Thermal felt in a mattress

Thermal felt (heat-pressed felt) is a non-woven material consisting of natural and synthetic fibers. It is one of the most popular materials used in combination with other materials in the production of modern mattresses.

Thermal felt (heat-pressed felt) is a non-woven material consisting of natural and synthetic fibers. It is one of the most popular materials used in combination with other materials in the production of modern mattresses.

The content of the article

Purpose of thermal felt in mattresses

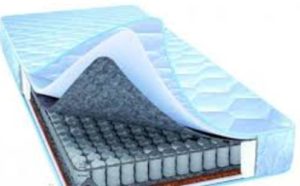

Thermal felt, used in mattresses with orthopedic properties, protects the coating. The design of the mattress provides for the separation of the spring block from the covering with a layer of thermal felt. Thanks to the properties of the material, uniform spring pressure on the human body is ensured over the entire surface of the mattress. The mattress gains comfort while maintaining the required level of firmness.

Thermal felt, used in mattresses with orthopedic properties, protects the coating. The design of the mattress provides for the separation of the spring block from the covering with a layer of thermal felt. Thanks to the properties of the material, uniform spring pressure on the human body is ensured over the entire surface of the mattress. The mattress gains comfort while maintaining the required level of firmness.

Thermal felt composition

The composition of the material is not strictly regulated, so product manufacturers independently establish the proportions of fibers of natural and synthetic origin. Wool, cotton, jute and flax fibers are used as natural raw materials, occupying up to 60% of the volume of thermal felt. The presence of synthetic fibers is limited to 35–40%. However, there are also examples of thermal felt where synthetics are not used at all, or where only synthetic components are present.

Among the fibers of synthetic origin, the most widespread are polypropylene and acrylic. Polypropylene has a number of worthy qualities: it is durable, reliable and resistant to high loads.Acrylic has a low level of thermal conductivity. In addition to these materials, a number of manufacturers use polyester and polyamide fibers as components in thermal felt.

Characteristics of thermal felt

Thermal felt is supplied in sheets just over 2 meters wide, which is wide enough to make a mattress, ensuring minimal waste. The main characteristics of thermal felt, which is popular among manufacturers and consumers, include:

Thermal felt is supplied in sheets just over 2 meters wide, which is wide enough to make a mattress, ensuring minimal waste. The main characteristics of thermal felt, which is popular among manufacturers and consumers, include:

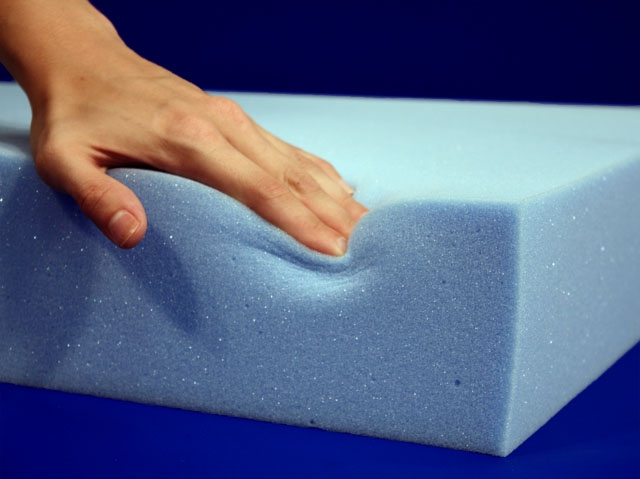

- Density of the material. The surface density of approximately 1 kg/sq.m provides a high level of tensile strength and low deformability. In the most traditional modifications of mattresses consisting of spring blocks, thermal felt acts as an insulating layer of polyurethane foam. This method of arrangement allows for comfortable operating conditions for the top layer of the mattress;

- Elongation at break and tensile load. These characteristics indicate the amount of stretch of the material and the amount of body weight that the mattress can withstand without fear of damaging the thermal felt;

- An indicator of durability, that is, resistance to physical wear. The material, having quality indicators, does not lose its properties over a long period of operation;

- Thickness. The indicator is 3 mm or more, it may vary depending on the manufacturer and models of mattresses produced;

Attention! It is a hygienically safe material, can be used by allergy sufferers and does not have a polluting effect on the environment when destroyed.

Production Features

The technology for producing thermal felt involves the use of specialized equipment - plucking and carding machines that perform operations to prepare fibers for further processing. Then the fibers are mixed and formed in a special machine, after which the material is bonded by needle punching (stitching method) or thermal bonding. To ensure reliability, many manufacturers use the thermal method after flashing. During the thermal bonding process, the workpiece is heated up to temperature 1900 WITH and perform pressing using a unit specially designed for this purpose. After melting the synthetic fibers, the material is reliably bonded.

The technology for producing thermal felt involves the use of specialized equipment - plucking and carding machines that perform operations to prepare fibers for further processing. Then the fibers are mixed and formed in a special machine, after which the material is bonded by needle punching (stitching method) or thermal bonding. To ensure reliability, many manufacturers use the thermal method after flashing. During the thermal bonding process, the workpiece is heated up to temperature 1900 WITH and perform pressing using a unit specially designed for this purpose. After melting the synthetic fibers, the material is reliably bonded.

Important! Experts recommend choosing mattresses from a mixture of thermal felt, natural and synthetic fibers. It is the filler of this composition that has appropriate hygienic properties, high wear resistance and strength.

Among the variety of fillings, many prefer to choose mattresses with thermal felt, taking into account their natural origin. Creating a healthy microclimate in the bedroom, natural felt is well ventilated, dries quickly and does not absorb odors. However, modern artificial analogues are not inferior to natural felt in terms of characteristics. They also have hypoallergenic properties, are breathable and have other advantages.