How to make a mattress

Sleep is a very important process in a person’s life, since a person’s well-being during the day depends on it. To have a sound and proper sleep, you need a comfortable sleeping place, which is not complete without a good mattress.

Sleep is a very important process in a person’s life, since a person’s well-being during the day depends on it. To have a sound and proper sleep, you need a comfortable sleeping place, which is not complete without a good mattress.

There are a large number of models on the modern market, but their prices are not affordable for everyone. It will be interesting to try to make a mattress with your own hands, but if you do not have sewing and creativity skills, then it is better not to experiment, but to buy a mattress in a store.

The content of the article

Spring mattress and its manufacturing technology

The work on making this product will take very little time if you listen to our advice. For the process you will need a set of materials:

- Independent spring block;

- Heat-set felt;

- Foam rims;

- Rubber-based adhesive;

- Case.

Provide yourself with a work desk large enough to accommodate your future mattress and make it comfortable for you to work on.

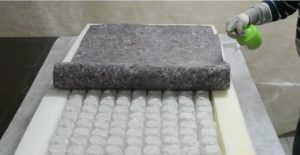

1 step

Take the 4 foam rims that come with the kit. Glue them together by covering the desired areas with glue.

Step 2

After the box is ready, place the spring block inside.

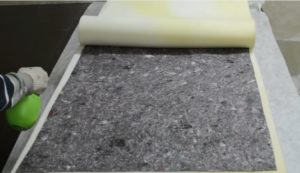

Step 3

Cover the entire top with glue, then spread heat-set felt in the middle. Then do exactly the same on the other side.

Step 4

Also spray glue over the entire surface, take a foam pad and cover the top of the mattress with it. Then do the same steps on the other side.

Step 5

Let the glue in the mattress dry for about 30 minutes, after which you can wrap the finished mattress with a cover.

Visual video:

Foam mattress and the secrets of its manufacture

For work you will need the following materials:

For work you will need the following materials:

- Foam rubber is the basis of the product, so its choice should be taken responsibly;

- Material for the cover;

- Felt;

- Glue for the base.

The main component of the whole process is the choice of foam rubber. Another name for the material is polyurethane foam. It is classified according to its softness. When choosing a material, you need to pay attention to its density - this directly affects the service life of the product.

The standard version is intended for children's mattresses. If the material is of increased rigidity, then it can withstand loads of up to 100 kg. Latex foam rubber is suitable for luxury furniture models.

Polyurethane is a common material that is most often used for making mattresses; it has the following advantages:

- Has low thermal conductivity;

- Does not burn on its own;

- Affordable price;

- Quick recovery of shape;

- Easy to care for;

- Vapor tightness;

- Moisture resistance;

- Lightness of the product.

Despite its advantages, doctors do not recommend using this material in its pure form, as it is too soft. When making a product, it is necessary to add additional elements, for example, coconut coir. Having decided on the choice of foam rubber and additional elements, you need to clarify the thickness of the mattress. It is calculated by weight.It should be understood that the greater the load on the product, the thicker the foam layer required. For example, for a thin person, you can make a layer thickness of 10 cm; it is perfect for comfortable sleep and supporting the spine. If the weight is more than 60 kg, then a little more foam is required, from 15 cm.

The material is classified according to its level of rigidity. Soft foam rubber is similar to a feather bed, it is comfortable, but harmful for constant use, as it negatively affects the spine. Medium hardness allows you to sleep comfortably and not harm your health. It quickly restores its shape and does not require additional elements that increase rigidity. An increased level of rigidity is achieved by adding coconut coir - this material is considered orthopedic.

After the correct selection of component materials, you can begin the mattress manufacturing process. A base is cut out, the dimensions of which must correspond to the sleeping area. It is desirable that the foam rubber is a single piece. But if you need to periodically fold it and put it away in a closet, then you can make several elements, along the cut of which there will be a bend that allows you to easily fold the mattress.

The cut pieces of material are covered with felt, and then a special cover is put on the product.

Important information: Foam rubber should not be cut using hot nichrome wire. This will affect the safety of the product as a whole. Foam rubber in contact with a heating element can release cyanide, which negatively affects the human nervous system even in minimal doses.

Making a mattress from foam rubber takes less time than a spring version, the main thing is to choose the right stiffness of the material.

More information about mattress fabric

The cover for the product is also an important aspect, the choice of which requires careful consideration. All materials are divided into knitwear and jacquard. Durable and wear-resistant materials are considered to be varieties with the addition of spunbond or synthetic padding with quilting.

The cover for the product is also an important aspect, the choice of which requires careful consideration. All materials are divided into knitwear and jacquard. Durable and wear-resistant materials are considered to be varieties with the addition of spunbond or synthetic padding with quilting.

Knitwear is distinguished by its structure and is made by connecting loops together, which makes it possible to enjoy its additional characteristics:

- The knitwear stretches well, which ensures a tight fit to the product;

- Has elasticity;

- Soft and pleasant to the touch.

Among the positive qualities, we can note the ease of care of a cover made of this material; in addition, it is quite durable and wear-resistant.

Jacquard is distinguished by its complex weaving. It has no lint, which ensures the mattress cover is perfectly smooth. A mixture of materials is used to produce fabric, which allows achieving a high level of density and relief. It is good to choose jacquard, which contains a large percentage of cotton. Jacquard is pleasant to the touch and is distinguished by its safety.

conclusions

Making your own mattress can take a lot of time and effort. But the product is worth it. The main thing here is to strictly follow the instructions and select the right materials. The advantage of making a mattress yourself is that a person can choose individual sizes, choose their own padding and choose the material for the front side of the product.