DIY thermal imager from a camera

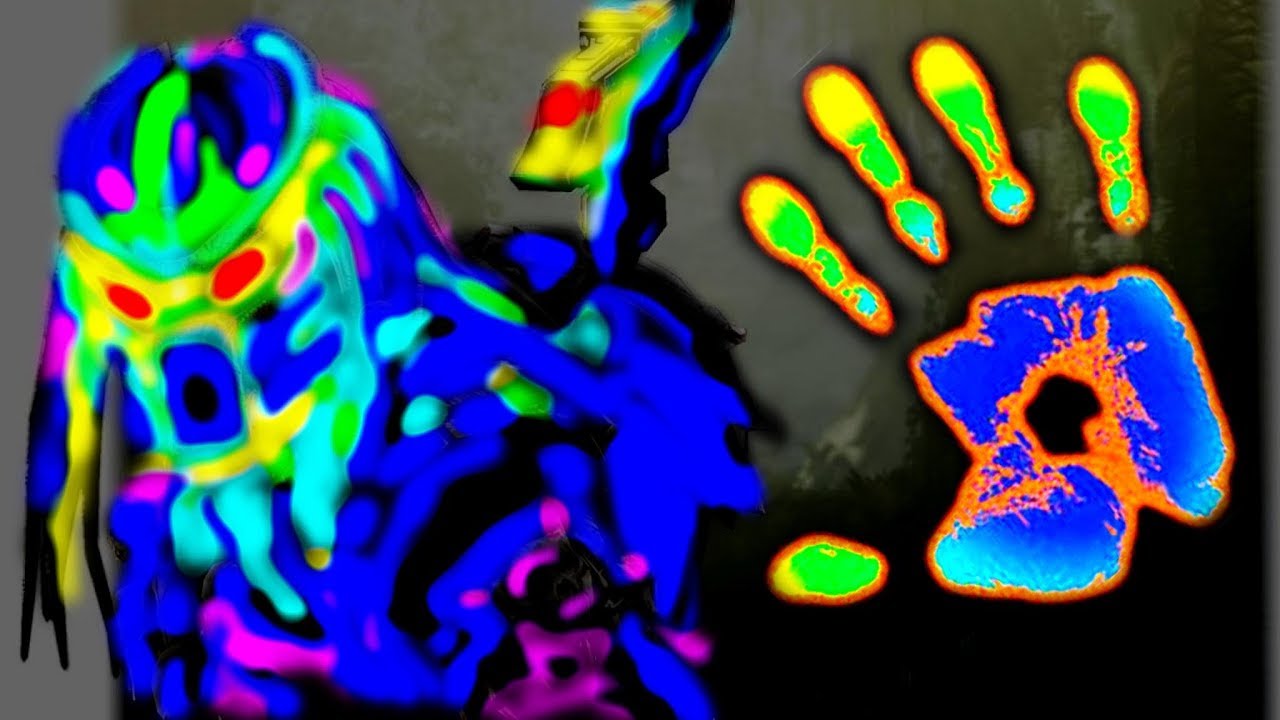

Many people probably watched the movie “Predator” and were a little jealous of the ability to see thermal radiation, like the notorious alien. It turns out that this feature can be used not only for hunting, but also in many areas of production and medicine. And this pleasure is not so expensive - a thermal imager, and you can make it with your own hands even from a camera a la a point-and-shoot camera. How to do this and where the device can be used is the topic of today’s article.

The content of the article

What can you use a thermal imager for?

In addition to special effects in science fiction films, the device finds the following applications:

- control of energy leakage — since poor contact causes heating of the conductors, a thermal imager makes it possible to easily identify this problem;

- grade thermal insulation properties buildings under construction;

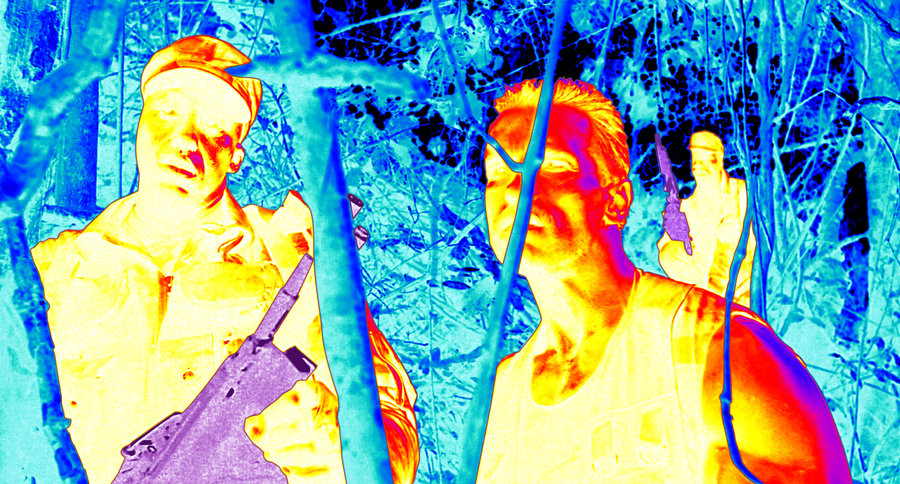

- as an alternative night vision device - to detect enemy manpower and equipment;

- from the rescuers — to detect fires, search for people, possible exits from premises and assess the situation;

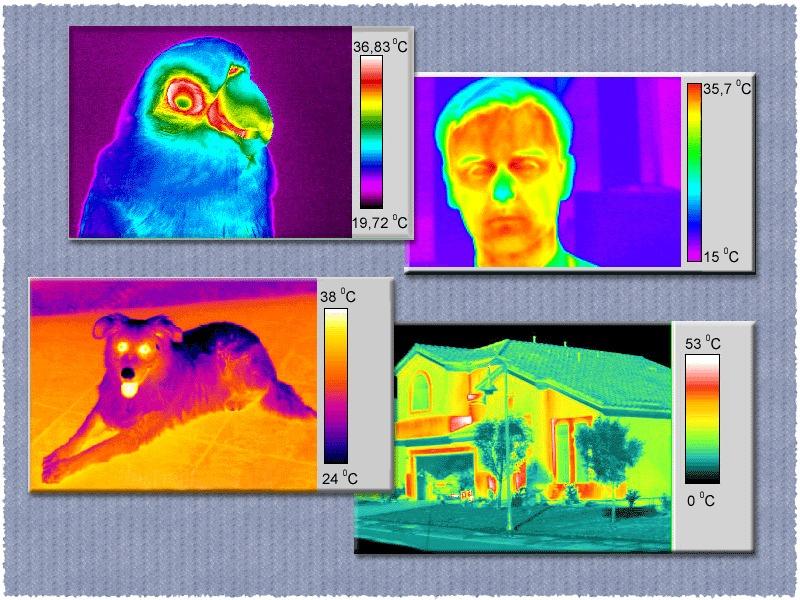

- in medicine — to identify people with elevated temperatures in a crowd and to identify pathologies of the body, including cancerous foci;

- in metallurgy and mechanical engineering — to get an idea of the heterogeneity of heating of objects.

In addition to the above, the thermal imager is used in astronomical telescopes, veterinary control and night driving systems.In short, the range of its use is definitely not limited to hunting.

Operating principle of the device

Without going into the jungle of physics, I will tell you: all bodies with a temperature above absolute zero emit heat. Mid-infrared (7-14 microns), invisible to the human eye, the maximum degree of radiation for bodies with a temperature of -50 to +50 degrees. The display of the thermal imager reflects a color picture of the temperature difference of the surface being studied. Color gradation occurs in the range colors of the rainbow from purple to red, depending on the degree of surface heating.

For some production processes temperatures of several hundred degrees are interesting. The wavelength of radiation in this spectrum is shorter - 3-7 microns. But according to the principle of operation, the devices used for measurements, regardless of operating temperatures, are completely identical.

If the body has a temperature of about a thousand degrees, auxiliary devices are no longer needed, the glow is visible to the naked eye.

Device operation includes three main stages:

- registration of radiation in the infrared range;

- converting recorded data into digital values;

- displaying the resulting thermogram, that is, a heat map of the surface of the observed object.

Modern devices allow such conversions and obtain images with virtually no delay, in real time.

How to convert a camera into a thermal imager

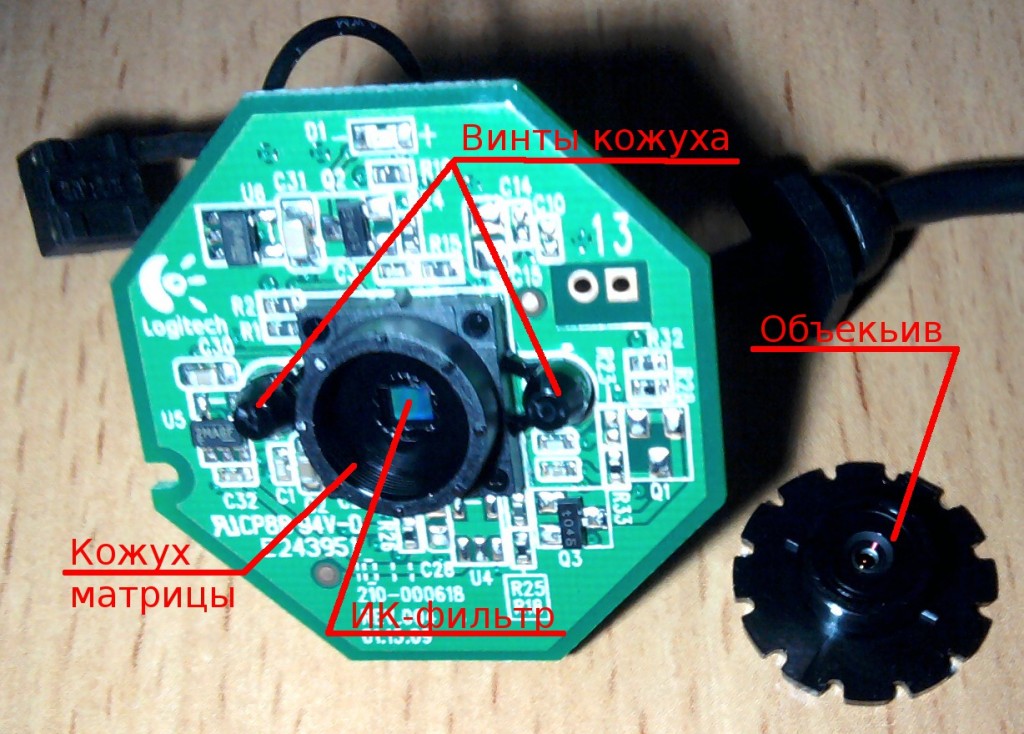

In fact, you won’t have to redo anything special. Initially, the camera matrix perceives infrared radiation. Another thing is that manufacturers put in them so-called thermal filters, which reflect or absorb infrared radiation falling on their surface.

In another way, this filter is called a thermal mirror, in the bourgeois version - "hot mirror". As a result, the spectrum perceived by the camera matrix becomes approximately identical to what the human eye sees.

If you remove the IR filter from the camera, it will begin to work as a thermal imager. You can (but not necessarily) install it instead visible spectrum filter. As practice shows, it does not play a special role and has virtually no effect on the operation of the device.

In addition to the camera, the following can serve as test subjects (or victims - depending on how the process goes) for the manufacture of a miracle device:

- smartphone;

- camcorder;

- Webcam;

- IR sensor.

I won’t describe the technology for converting them, since that’s a completely different story. And the technology for modification is more complicated, and the costs are an order of magnitude greater.

Why are thermal imagers so expensive and all with low resolution? Apparently manufacturers don’t understand that all this can be easily and simply set up. And here we have a guy who knows, but won’t tell anyone - well done, he probably works as a hero of the intelligence officers.

But do not forget that it will not work, since there is nothing to filter the background radiation. At most you can distinguish a piece of ice from magma, no adequate accuracy.

EEEEEEEEE... I'm an ass, both the author and Prosha - I have no words, they sit on the Internet and talk heresy. What they make from a camera and similar equipment to a thermal imager has a far from mediocre relationship, have you even held a converted device in your hands? There is no need to mislead users.

If you want a thermal imager with your own hands, buy an IR matrix, they are usually very expensive, and what I saw on the electronics market (by the way, there is one) is a maximum of 640 by 480 resolution, but there is a very small resolution for the money available. But in reality, a thermal imaging matrix doesn’t need much resolution; then it’s all a matter of firmware. There are a bunch of good guides on how to assemble and flash a real thermal imager, if you don’t need mega resolution and need to look at the wiring, corners of the house, batteries.

And what’s in the article is complete heresy, I screamed.

that's for sure.

for the author - well, you may see the near infrared, but what’s the point, the main meat is in the far infrared, which is precisely what microbolometer devices perceive. here 80x80 is expensive, not to mention 640x480, otherwise everyone is a fool, I’m the only one - d’Artagnan on a horse and in a white hat!

Lies. I have an old unnecessary camera lying around. I took it apart and removed the filter. AND…. All photos are in pink.

Mini thermal imagers for 5000 rubles appeared on the juma.

Converting a gas cylinder into a communications satellite, I won’t actually describe the nuances (long and expensive), but it should really work.

The whole point of the post: “you can do it, but of course I won’t tell you how”

Bredopost

I laugh at the article and at the stupidity of ignorance of elementary physics and electronics. In essence, what is described will turn out to be crap from a broken camera.

Since ordinary optical glass is opaque in the mid-IR range, the optics of thermal imagers are made from special materials. Most often it is germanium, but it is expensive, so chalcogenide glass and zinc selenide are sometimes used. For laboratory purposes, optics can also be made from certain salts, such as table salt, which are also transparent in the required wavelength range. Yes, and basically it’s optics, but not like a matrix.

The author gives you two.

Auto RU-

Thermal imagers have been made from cameras for a long time. The whole difficulty is that the glass of the lens absorbs infrared rays. And special materials for infrared lenses are incredibly expensive. Plastic, unlike glass, transmits infrared light. But no one will offer you a ready-made plastic lens; you’ll have to make it yourself. However, I have seen aspherical magnifiers for sale on the Internet. For the sake of cheapness, they are cast from plastic. They cost around two hundred rubles. All that remains is to make the body.