DIY mosquito net

With the arrival of warmth, through open windows and vents, “uninvited guests” - flies, midges, wasps, mosquitoes and other insects - begin to enter the premises. Plus, the wind brings dust, poplar fluff and various debris. Mosquito barriers on windows and balcony doors help protect your home from all these “delights”.

With the arrival of warmth, through open windows and vents, “uninvited guests” - flies, midges, wasps, mosquitoes and other insects - begin to enter the premises. Plus, the wind brings dust, poplar fluff and various debris. Mosquito barriers on windows and balcony doors help protect your home from all these “delights”.

The content of the article

Types of mosquito nets

Just 15 years ago, insects were prevented from entering the room using ordinary gauze or tulle, which were attached to the window with pushpins. Such “decoration” on the windows looks unaesthetic and will last only a few months.

Today, in any hardware store you can purchase a special mosquito net quite inexpensively. People call it a mosquito net or “mosquito”.

This mesh fabric is fiberglass coated with a thin layer of PVC. Easily attaches to wood, plastic, aluminum and combination surfaces.

The advantages of this material are:

- strength and long service life;

- resistance to temperature fluctuations;

- resistance to sunlight;

- high degree of protection against dust and insects;

- the ability to freely transmit light and air;

- environmental friendliness and absence of unpleasant odor;

- acceptable cost.

The mesh fabric most often has a width of 1.5 - 1.6 m. This indicator varies - each manufacturer has its own standards. Cells have different sizes. For windows, canvas with cells from 0.1 cm to 0.3 cm is most often used.

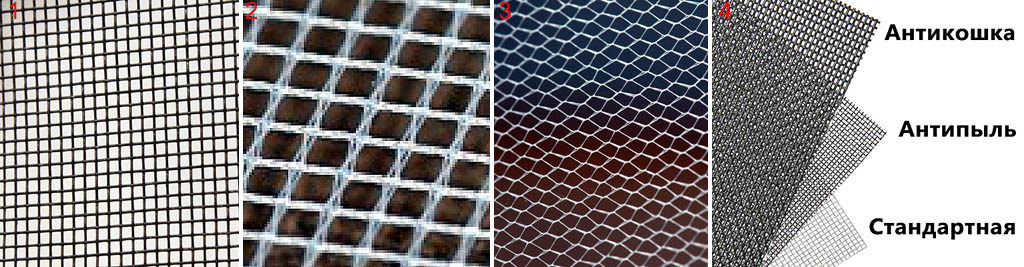

Manufacturers produce several types of mesh fabric, depending on its appointments:

- "standard";

- "external";

- "elite":

- “anti-dust” and “anti-pollen”;

- "anti-fly";

- "anti-cat";

- "maximum view"

Most modern windows are metal-plastic. They are equipped with mosquito barriers. Their design is designed in such a way that it does not impede the functioning of the windows at all; they are easy to install and remove and are inexpensive.

By installation location mosquito nets are divided into two groups:

- window;

- door

By mounting method:

- external;

- internal.

By construction types:

- frame (most popular);

- swing gates (like gates);

- sliding;

- roller shutters (roll);

- pleated (accordion-shaped).

We decide on the design and material of manufacture

If the mosquito net breaks during operation or flies away due to a gust of wind, and also if when installing windows it was decided to save on it, it is easy to make a mosquito net yourself, and it will cost very little.

In order to decide what exactly you need, you should consider a number of factors:

- type of building - private house or apartment building;

- on what floor is the housing located?

- type of window material – metal-plastic or wooden;

- opening method - rotary or folding;

- presence of pets;

- presence of construction experience.

Based on the above points, the type of structure, type of material and method of attaching the mosquito barrier are selected.

It is clear that if the apartment is on a high floor, then the internal fastening method will be suitable. In a one-story house, you can install nets outside.

If you live in the tundra, where there is a lot of midges, or in the steppe region, where there is a lot of dust, you should choose a mesh with a smaller cell size. If there is a cat in the house, then it is better to choose “anti-cat” canvas.

You need to decide on the color of the mesh. A light canvas blurs the picture outside the window, making it fuzzy and low-contrast. Gray, brown and black will make it clearer and less blurry, but dust and dirt will be visible on it, and green will be pleasing to the eye.

Attention! In pursuit of cheapness, you should not choose mesh of dubious quality or cheap Chinese; it is better to purchase fabric from well-known manufacturers. Low-quality material begins to crack and crumble after the first season of use.

If you decide to use a frame structure, you need to decide on the method of attaching the mesh to the frame. The most common and reliable is the Z-shaped profile. Plungers and staples are often used.

Taking measurements to make a window mesh

“Measure twice and cut once” - this proverb is very relevant in this case. Not only the appearance of the window will depend on the accuracy of the measurements, but also whether the mosquito barrier will be able to perform its task efficiently and will not become an obstacle when opening and closing the window.

Measurements are made using a tape measure or measuring tape.With the window open, measure the width and height of the window opening along the inner edges of the frame, from one sealing gum to the other.

The mosquito net is laid out on a flat surface. Markings are applied with a marker or pencil and a pattern is made.

Attention! When cutting the mesh, you can focus on the cells, in which case the cut line will be smooth.

Manufacturing process of mesh with frame

Fairly easy to implement - frame structures. This is the main reason for their widespread use.

Option No. 1 - from a cable channel

This option is the simplest and least labor-intensive compared to others. The dimensions of the frame - length and width have already been measured by us and the mesh has been cut out.

What you will need:

- cable channel - 1.5 x 1.0 cm (its length is selected in accordance with the perimeter of the window opening);

- plastic profile with U-shaped section;

- flat metal corners – 4 pcs.;

- aluminum rivets (diameter – 7–10 mm);

- riveter;

- drill with 4 mm drill bit;

- hacksaw for metal;

- miter box.

General assembly algorithm:

- Make markings on the cable channel along the length and width of the window opening.

- Saw off the pieces of cable profile at an angle of 45 degrees and remove the covers from them. For this stage of work, it is very convenient to use a miter box, which will allow you to saw off the profile at an angle of 45 degrees.

- On a flat surface, fold the future structure into a rectangle.

- Place metal corners in the corners and mark the holes.

- Drill holes and connect the structure using rivets.

- Place the mesh on the finished frame, making sure there are no folds, and close the lids.

- Use a hacksaw to saw off two pieces of a U-shaped profile with a length equal to the width of the frame.

- Fasten the pieces of the U-shaped profile to the window at the top and bottom so that the structure easily fits into them.

Option No. 2 - from a purchased kit

This option is more difficult to manufacture than the first and more expensive.

At a hardware store you need to purchase a ready-made kit for making a frame and a mesh. Prepare the necessary tools and assemble the frame according to the instructions.

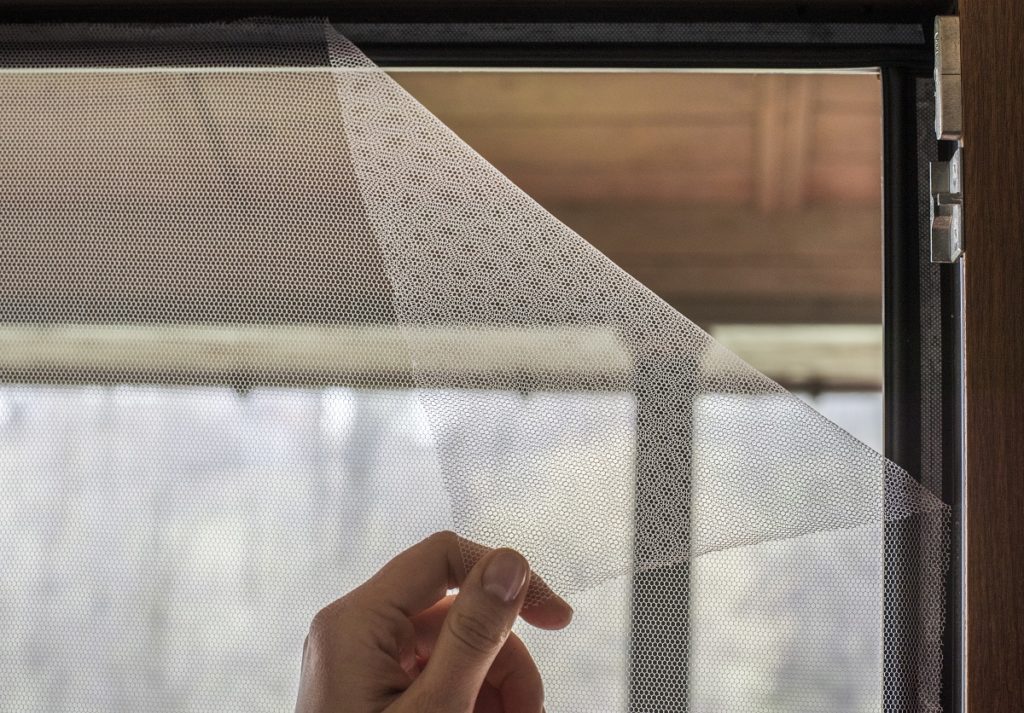

Features of manufacturing a frameless design

The cheapest way is to install a mosquito net directly on the frame. The easiest one to make yourself is a frameless or frameless mosquito net.

To make a frameless structure, it is necessary to make a gap on the mesh fabric of 20–30 mm. We remember that the measurements have been made and the “mosquito” has already been cut out.

Option No. 1 - in place of the sealing cord

What you will need:

- rubber or any other cord, or clothesline with a diameter of 0.4 cm;

- scissors;

- a tool for “pressing” the cord into the groove - the handle of a screwdriver or knife.

Manufacturing algorithm:

- Carefully remove the sealing cord from the groove so as not to damage it.

- If the window is no longer new, then dust and dirt have probably accumulated in the groove. Wash it with a damp cloth.

- Starting from the top corner, along the perimeter, the cord along with the mesh is pressed into the groove. In this case, it is necessary to maintain the uniformity and quality of the fabric tension.

Attention! The sealing gum is washed, dried and stored. In the fall, the cord with the mesh is removed from the window frame, and the sealing cord is placed in place. The mesh and cord are washed and put away until spring.

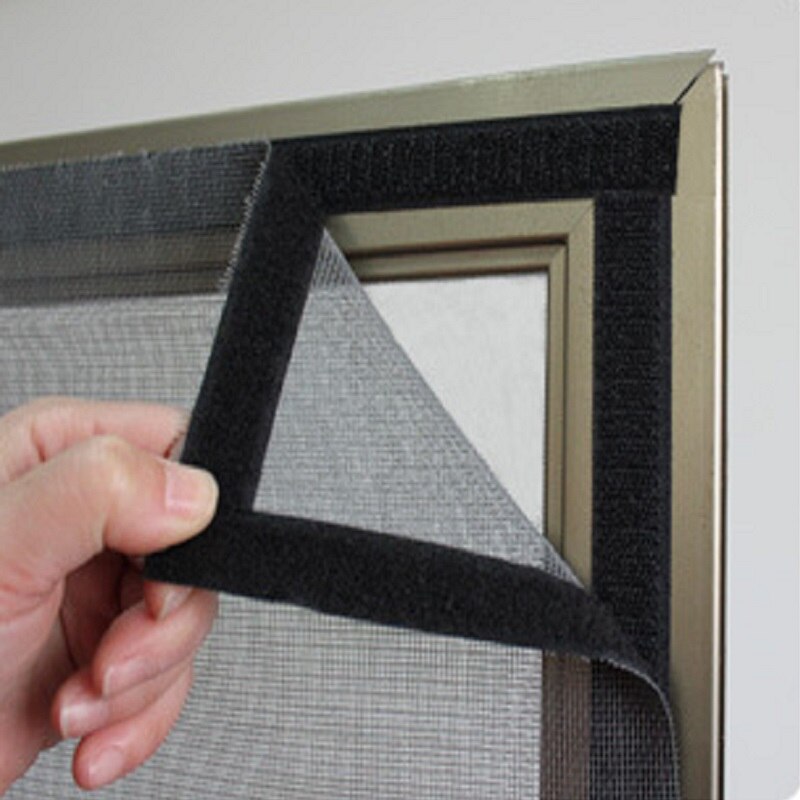

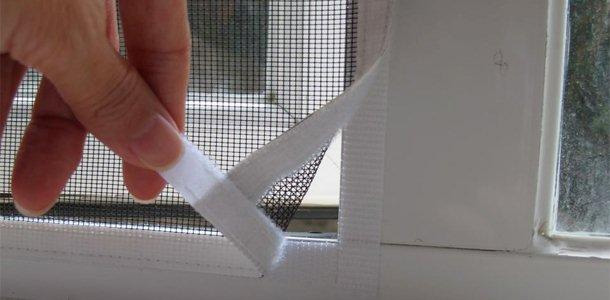

Option No. 2 - Velcro

What else will you need besides the mesh:

- tape measure or centimeter;

- contact tape - Velcro, its length = the perimeter of the window opening;

- glue or liquid nails;

- threads, needle;

- scissors.

Manufacturing algorithm:

- According to the measurements taken, cut the contact tape into 4 parts.

- Rinse the frame thoroughly and degrease it with solvent or alcohol.

- Place the sticky (spiky) part of the tape on the frame coated with glue.

- The other part is sewn around the perimeter to the mesh fabric manually or using a sewing machine.

- Connect both parts of the contact tape, and the mesh will be firmly fixed to the frame.

Attention! When sewing Velcro to the mesh, you should leave a piece of 3-5 cm; you can pull this “tab” to separate the mesh from the frame.

Self-made mosquito nets are easy to maintain. It is enough to wipe their surface with a wet sponge and detergent dissolved in warm water.

Attention! Before washing, blow off particles of dust, debris and fluff from the mesh fabric with a cold hairdryer or vacuum at low speed. The frame structure is easy to clean with running water from the shower.

A self-made “mosquito” will protect the house from “unwanted guests,” garbage, dust, and will protect against pets and birds falling out of windows, as well as from various objects, such as flowerpots, falling down.

As you can see, making a mosquito net is very easy and quick. You don't have to be a 3rd grade carpenter to do this. It will cost much less than a “ready-made” one!