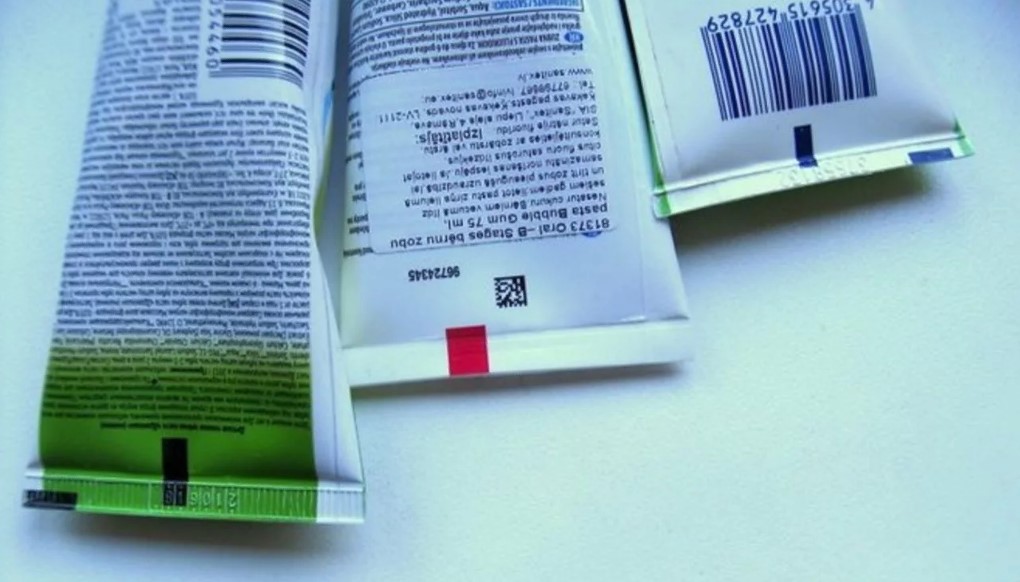

The square on the toothpaste package: check what color it is and what it means!

To keep your teeth healthy and beautiful, proper daily care is required. One of the essential oral hygiene products is toothpaste. Store shelves are overflowing with various tubes. You should know how to choose the right pasta and Why is the color of the box on packaging important?.

The content of the article

How to choose the right toothpaste?

Certain criteria allow you to purchase a safe product that will not harm your teeth. When choosing pay attention to the following points:

1. Compound. You should avoid products containing parabens, which can cause harm to the human body if used regularly.

Important! Fluoride is essential for teeth. However, pastes should be used with caution. Products with a high fluoride content can only be used as prescribed by a doctor.

2. Individual needs. The condition of teeth varies from person to person. There are also different pastes: for sensitive teeth, with a whitening effect, and others. When choosing a product, it is worth considering, in addition to its main action, the desired effect, as well as the condition of the oral cavity. If sensitivity is increased, conventional remedies will only do harm.

3. Expiration date and place of purchase. Be sure to check until what time the product can be used. Some people ignore this rule and purchase expired funds. For purchases, you should preferably choose pharmacies rather than supermarkets.

What do the squares on a tube of toothpaste mean?

In addition to the selection recommendations described above, there is an important nuance when buying pasta. On each package you can find squares of different colors. Many do not pay attention to them, but in vain. After all They are the ones who, like a litmus test, show and tell how safe this product is.

Green

Most of the composition has natural, healthy ingredients. Safe and most useful product. There are no chemical components in the product with a green square.

Blue

This means that the composition, in addition to natural components, also contains chemical ones. The product does not have a completely useful composition, however, it should not be considered unsafe.

Red

Signals about the presence of hazardous chemicals among the ingredients. Although their number in this case is minimal, you should refuse to use such a product.

Black

This square indicates the greatest danger.. The products he mentions have an almost entirely chemical composition. There are many harmful components among the ingredients. You should not use such pastes.

When choosing, it is worth studying not only the composition of the product, but also the color of the square on the package. This is especially true for children's pastes, where safety should be maximum. This will prevent harm to the oral cavity and the body as a whole. The same markings are on all creams; when purchasing, pay attention to the color of the squares.

The article is complete nonsense! Don't disgrace yourself... Blend-a-honey is the safest toothpaste. There is a program with Otar Kushinashvili, where hygiene items and products are tested. Bl.-a-Honey and Forest Balsam won among all other pastes. Ah, these squares mean the cutting line of the packaging and nothing more.

Well, you give it! This duck about the color of the square is already 5 years old. The myth has long been dispelled. This square allows automation at the factory to seal the tubes. That's all.

Santa probably comes to the author and the tooth fairy also believes in elves

I need to write something like this

The purpose of this funny fake is to attract visitors. And not just visitors - came/left, but also commentators.

And the goal was successfully achieved!

Nonsense! If you approach the choice of pasta based on this article, then they are all very dangerous! Basically all the tubes have black squares. And what is the point of manufacturers then applying them so that people don’t buy them? I understand that if these squares were drawn by some research institute based on the study of each batch, then it would be a different matter.

RAVE.

This is a mark for the machine that seals pastes. The same machine that makes tubes from tape from a drawn label. And the color is determined by the drawing itself. The most contrasting one is selected.

If you look at the blend-a-med photo, there are two colors. Blue and red. Of course the mark will be red. There is simply no other ink when printing. Another paint will cost more

An old joke, I already thought everyone was aware, but since people still fall for this bait (well, or here, and there are many more on the Internet), let’s put everything in its place. So what does the version sound like:

Have you ever noticed that every tube, for example, with cream, always has a square on the back side. They are: black, dark brown, dark blue, dark burgundy (generally dark colors); They also come in RED and GREEN. So what do they mean?

Dark squares mean that the product you are using is made entirely of CHEMICALS!

Red squares mean that the product is approximately 70% CHEMICAL and 30% NATURAL PRODUCT.

Green squares mean that the product you used is WITHOUT chemicals!!! Consists only of NATURAL SUBSTANCES

I’ll try to figure out why these squares are needed anyway.

It turns out that the whole point is in the printing production of the tubes themselves. The tube production process occurs as follows: first, the design of the future tube is developed, and then the developed design is introduced into production. But not all designers’ ideas can be reproduced on a color printing machine. For most machines there are only 4 colors - SMUK (Cyan Magenta Yellow Black). Therefore, the developed design goes to the pre-press department for further processing, where problematic design elements are processed: unnecessary colors are removed, replaced with spot colors, and other technological issues are performed.

Let's say the tube design includes an image and blue text. In this case, application is allowed, the image of blue color is made in color - (SMUK) with further processing.But applying text and barcodes in this way is prohibited; printing such elements by superimposing two colors on top of each other is unacceptable, since if the colors do not match, the text will not be readable and the barcode will not be read. For these reasons, at the prepress stage, the text and barcode are assigned a special spot color from the Pantone catalog. To recognize Pantone color, a photo mark (in the form of squares) is assigned; the photo mark must be the same color as the barcode.

Photo marks are also necessary for the following production reasons: horizontal - for precise cutting of the laminate sheet in height (when printing on a rolled laminate sheet); vertical - for precise positioning when soldering the tip of the tube (so that the solder is parallel to the image and text part, and not at an angle or perpendicular).

In order for the photo sensor to recognize a photo mark, there needs to be a contrast between the background and the mark. The maximum (desired) contrast is a white material and a black photo tag. If the design contains black, then both the photo tag and the barcode will be black; if there is no black in the design, then the maximum contrast color relative to the background is assigned. If the background is dark, then use a white photo tag. There are cases when there are no photo tags at all, and their role is played by design elements. Manufacturers often take risks by assigning a light color to the photo tag and barcode, since the barcode may simply not be considered a scanner in a store, and the photo sensor may not catch the tag when sealing the tip of the tube. To select the color of tags and barcodes, preliminary tests are carried out, but most often manufacturers do not take risks and release the product with black squares.

The process looks something like this: a continuous tape comes from a reel (foil on which a design is already applied on one side, for example, the inscription “toothpaste”). This tape goes into a machine, which cuts off a piece from it and makes a blank for the tube from this piece (rolls it around, glues or fuses the ends, etc.). Then toothpaste is poured into this unfinished tube, which goes along the conveyor with the screw cap down, and the top edge is “wrapped.” In fact, the color mark is necessary for precise positioning of the cutting location - so that the machine cuts the tubes in the right places and so that it doesn’t turn out that “tooth paste” is written on one tube, and “tooth paste” is written on the other, etc.

Hence the conclusion that the small squares and rectangles on the back of the tubes do not indicate the chemical percentage composition of the product, but serve for the printing production of the tubes themselves.

How old is this story about “squares”!!!! Truly there are no shortage of fools in Rus'!!! For those who are especially advanced, a square (stripe) serves as a mark for positioning the tube in the machine; the color is determined by the paint on the label!

The author doesn't care about any of this. Out of school habit, he simply copied it somewhere and posted it in his own name. He didn't even read anything.

That's right. I have been working on packaging equipment for many years and I confirm that this photo mark is needed only for the packaging machine and determines the place where the bag (tube...) needs to be cut and sealed. The color can be any determined by a photo sensor from those used on this particular package.

The square on the tube is printing markings. She has the same relationship to the composition of the paste as I have to ballet.