How to unscrew a nut with broken edges

It happens that the nut gets so stuck to the bolt that attempts to move it end with the edges on it simply being “licked off” by the wrench. It seems that the material is not bad - steel, but guess what... What should you do in this case? There are several methods for unscrewing a nut with broken edges. They will be discussed in the article.

The content of the article

Lubricant and spanner

If everything is not too advanced, you can try this technique:

- Metal brush Clean the surface of the threaded connection.

- Apply gasoline, kerosene, or lubricant like WD-40 onto the released nut and bolt. You can wrap them with a rag soaked in the specified composition and leave it like that for 20-30 minutes.

- After some time has passed, we try to unscrew the nut spanner wrench, just without fanaticism. The edges are already torn off, the key can jump off. In order for the rust scale to come off, you can lightly tap the connection with a hammer, just do not miss the nut or hit the thread.

Heavy Artillery - Gas Key

Due to the impressive leverage and comfortable grip, it may well be possible to cope with the task using gas key. But its dimensions, although they provide leverage, can prevent you from getting close to the threaded connection.

On a note! It is possible, and even necessary, to combine methods - treat the threads and nut with lubricant, and then use a gas wrench.

Grinder, file or hacksaw for metal

If there is absolutely nothing to grab onto, and the nut is no longer shaped like a hexagon, but like a cylinder, there is still a way out. Why not make the edges in a new way? The dimensions of the nut will already be smaller, but you can also take a wrench that matches the case.

Perfectly suited for such purposes grinder with metal disc. But this is a tool only for those who know how to use it. Whoever picked it up for the first time should immediately put it in its place and take it file or hacksaw. Or you can use a grinding wheel.

There will be more fuss with a hand tool than with an electric one, but most likely there will be no injuries. I think there is no point in describing how to make the edges - everything is already clear here. By the way, you don’t need to make all six faces. It is enough to remove the rounding on two opposite sides of the nut so that you can grab it with a wrench, or make something with a cross-section resembling a square.

Drill and pin

An alternative is to drill a hole of small diameter in the head of the bolt, into which to drive a strong faceted L-shaped pin. After this procedure, clamp the nut on the connection in a vice and, using the driven pin as a lever, remove the bolt.

Superglue or welding

If there is a nut of the same diameter and thread pitch as the one being unscrewed, why not connect them together using welding or superglue? After the connection has set, you can safely unscrew the welded (glued) nut. The main thing is not to damage the threads on the bolt during the welding process, otherwise the wrench is unlikely to help.

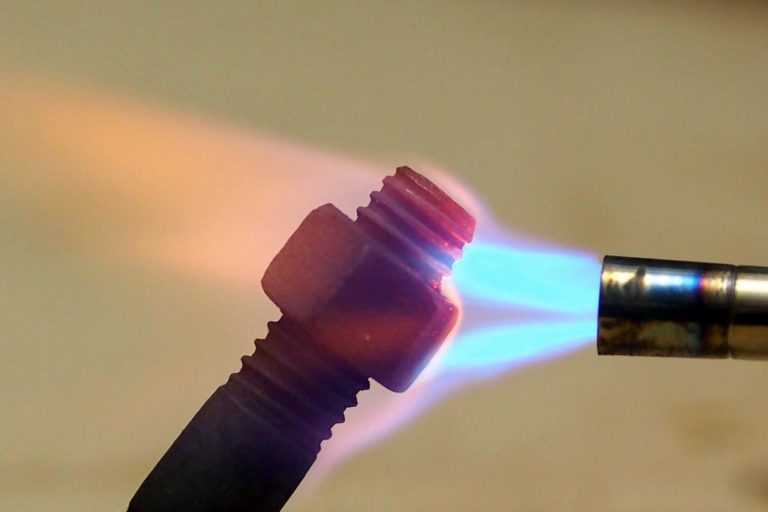

And if we’re already talking about welding, let’s mention another way to release threads: thermal. Its essence lies in the strong heating of the connection.When exposed to high temperatures, parts expand and the rust holding them loosens its grip. In addition, the bolt, expanding when heated, will slightly increase the internal diameter of the nut.

Then, after cooling, the diameter of the bolt will return to its previous dimensions, and a small gap between it and the nut will remain. I recommend injecting a little WD-40 into this gap to reduce friction. As a result, the trick of releasing the bolt may well work.

Hammer and chisel as the final argument

Let's say you tried the indicated methods, even tried to dance with a tambourine, but nothing worked. There remains one more technique, after which both the bolt and the nut can be thrown away with a clear conscience. We attach chisel to the thread, and hammer We apply a series of blows to it until the connection is destroyed.

If you have experience working with Bulgarian and you can get close to the thread with it, don’t waste time with a hammer and chisel. Cut the bolt calmly. However, as a result, it will not be possible to preserve the fasteners.

There are many more ways to solve the problem, each more exotic than the other. But if the described methods did not help, then others are unlikely to be useful.