How to unscrew a nut that won't come off

There are often cases when the nut sticks so tightly to the bolt that it is almost impossible to move it without stripping the thread. The main reason for this misfortune is the notorious metal corrosion. Over time, especially in a humid environment, oxidation of the threaded connection occurs. The second common reason is that a lot of dirt has accumulated on the threads, resulting in the same problem.

Whatever the reasons, the nut will not unscrew itself. We need to invent something. And what exactly is what will be discussed in the article.

The content of the article

Required Tools

In general, you can use a hammer, chisel and/or pliers, and with the help of this simple set and someone’s mother, convince the nut to move. But it’s better to follow the path of least resistance and use the following tools:

- spanners of the appropriate size;

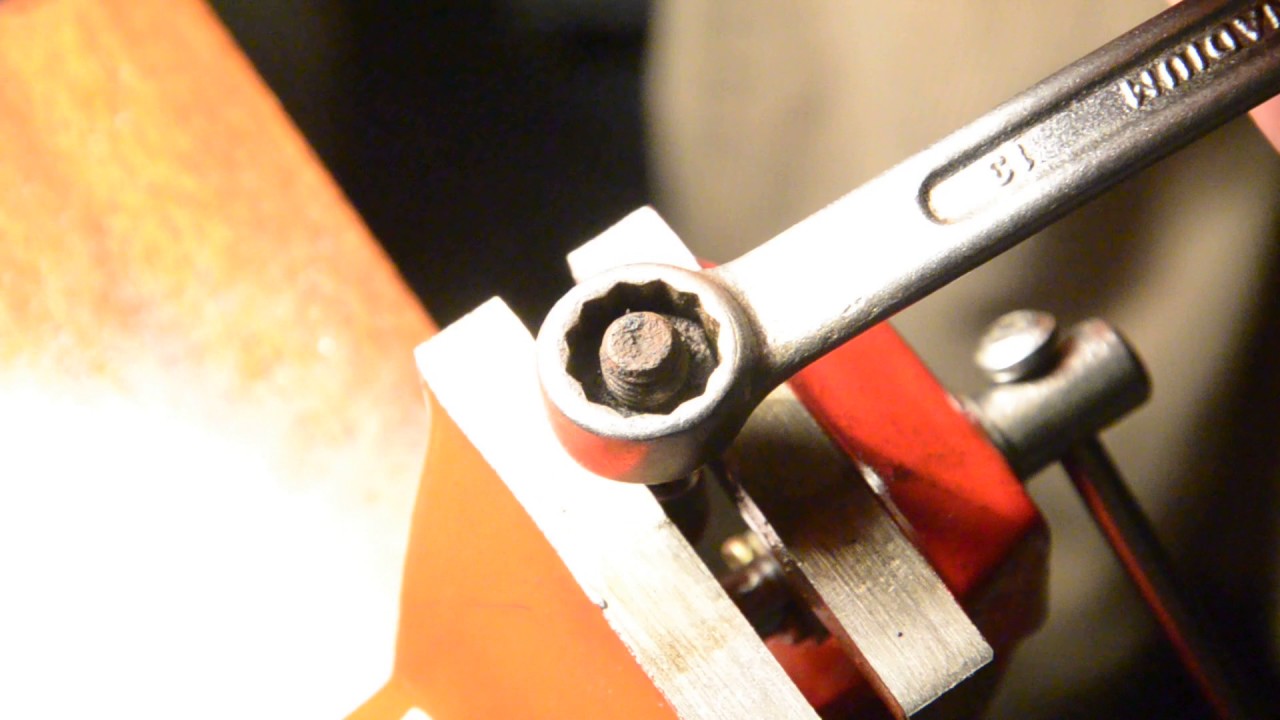

- socket wrench;

- a mechanical impact wrench and a set of sockets with a crank.

If you are not familiar with the above list, I strongly recommend that you get acquainted.

Precautionary measures

To prevent the process from ending in calling an ambulance, or at least applying bandages, follow these simple rules:

- use only serviceable tools;

- I remind you that the right-hand thread is unscrewed counterclockwise;

- make sure that the tool is securely fixed to the nut so that it does not break off at the most opportune moment;

- do not hesitate to use at least fabric gloves when working.

And of course, do not catch crows while working - be careful and careful.

Unscrewing methods

There are three main methods for unscrewing a stuck nut:

- dissolving rust and dirt;

- heating the nut;

- mechanical damage to the nut.

Let's deal with each of them in turn.

How to dissolve rust

The essence of the technique is a chemical effect on rusty threads and, as a result, a reduction in the friction force when unscrewing. It may be suitable for these purposes vinegar, alcohol, iodine, kerosene or gasoline. But it’s best to use a composition called WD-40, which is designed specifically for such purposes.

I will describe the methodology in detail:

- The nut is thoroughly moistened with the substance described above and allowed to stand for 15-20 minutes. Then they try to unscrew it. If this does not work, wrap it with a rag soaked in the composition used, or with a napkin. Again they wait for a while.

- Most likely, everything will work out, and success can be secured by hitting the nut with a hammer. Just don’t hit the bolt threads, otherwise you’ll make your task much more difficult. I recommend lengthening the wrench with a piece of pipe of a suitable diameter - the lever will be much stronger. It will be easier to move the nut out of place if you securely place the wrench on it and make a sharp jerk. Just don't pull clockwise!

- With a small thread diameter, it is very convenient to unscrew the nut by swinging, that is, working the wrench back and forth.

Heating process

Under the influence of high temperatures, metal tends to expand. As a result of such deformation, rust simply “looses its grip”, and the unscrewing process is greatly simplified.Suitable as a heating element construction hair dryer, gas burner, blowtorch - anything that produces a high heating temperature. Don't be afraid - you are unlikely to be able to melt the metal from which the fasteners are made.

How exactly to proceed:

- Warm up the connection thoroughly, and then try to get the process off the ground using a spanner wrench.

- Sometimes it happens that the edges of the nut are licked off, then the wrench is useless. In such cases, a socket head is welded to it, the entire structure is heated, and then it is unscrewed using a wrench.

Attention! Be careful when working - you can easily get a thermal burn, don't forget about gloves!

Mechanical impact

This method is resorted to if the previous two did not help or when there is no task to keep the connection intact. For work you can use hammer and chisel, grinder or hacksaw.

The essence of the technique is as follows:

- You can use a hacksaw or grinder to saw the nut along the axis of the bolt, and then removing it will not be difficult.

- There is another radical method - using a hammer and chisel. By driving it deeper, you can knock down the threads and increase the internal diameter of the nut. But this is completely, as they say, out of despair.

But the best way to combat acidification of compounds is to prevent it through timely applying lubricant. In this case, the service life of the fasteners will at least double.

- the best remedy for such purposes (much better than wd40) is Soviet simple dichlorvos. but the one they are releasing now is no longer suitable for these purposes. Apparently they changed the composition...

The author has never heard of nut-cutting nuts?

However, the methods outlined above are good, instead of wd they used to use brake fluid, by the way, I still use it and have never let me down, and it’s much cheaper than wd.

Did the author say something new?

Nothing new is said for me, but the methods are effective. It is possible without a mother if you have an aunt.

not everyone has them by the same author

said as with improvised means

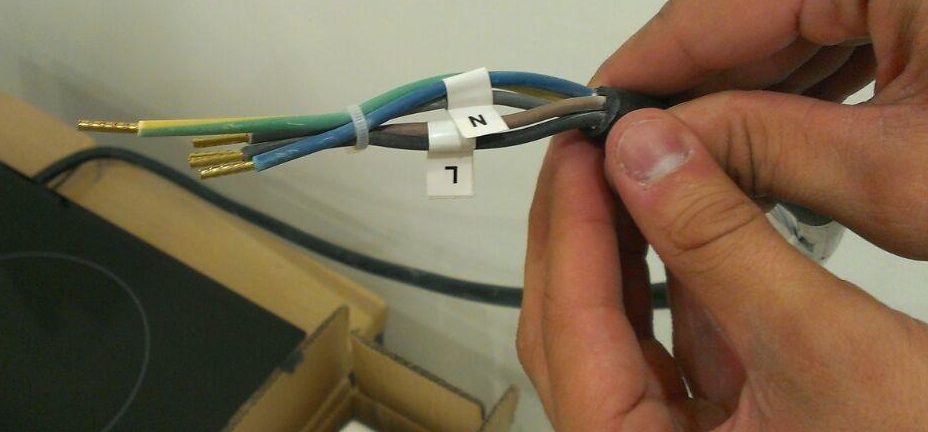

and why, judging by the photo?