How to cut glass at home without a glass cutter

Cutting glass with a professional tool is easy and convenient (especially after a number of unsuccessful attempts). But, firstly, not everyone has a glass cutter. And secondly, in the case of a one-time promotion or rare use, is it needed at all? After all, a professional instrument costs a lot, and a cheap Chinese one can disappoint with its “quality and durability.” And the result of the work too. Therefore, I propose to use methods that allow you to do it at almost no cost, and eat the fish without choking on the bone.

The content of the article

Twine

The point of the technique is to first heat the glass being cut and then cool it sharply. Under the influence of temperature changes, it will burst along the line of greatest contrast. The method is good if you need, for example, to cut a glass bottle or jar.

To do this, you need to soak the wool thread in alcohol, acetone, white spirit or some other flammable liquid. The twine is wrapped around the intended victim and set on fire. Then cool sharply with running water. If successful, you will hear a characteristic click. If it doesn’t work the first time, you need to repeat the ritual.

The technique may not work on bottles with thick walls, such as champagne cartridges. During the experiments, it’s a good idea to stock up on a fire extinguisher, otherwise the results may be very surprising, even until the emergency services and ambulance staff arrive.

Soldering iron

A straight cut is not always needed, and in this situation a file and soldering iron will help out. If you don’t have a soldering iron, a wood burning device will do.

The process is long but creative. First, mark the glass and use a marker to draw a cutting line on it. Then, at the edge, at the beginning of the mark, using a file, make a groove, which will serve as a guide. Having retreated a couple of millimeters along the line, use a soldering iron to heat the glass until a crack appears from the groove to the heating point. Then they retreat another couple of millimeters and repeat the process.

To make things go a little faster, the glass can be cooled with a damp cloth or dishwashing sponge.

Scissors

It’s worth mentioning right away that the technique allows you to cut thin glass, no more than four millimeters. When working, it is recommended to wear safety glasses and protect your hands with gloves. You will need a container with water, in which, in fact, everything will happen.

Water acts as a lubricant, allowing you to cut the desired shape using scissors. No matter what tool you come across will not work - you need something serious, like tailor's scissors. Cutting is carried out according to pre-applied markings. The cutting force is comparable to what is needed when working with hardboard.

One more nuance: the container must be deep enough so that the layer of water above the glass immersed in it is large. To what extent it can be verified empirically, you should first experiment with an unnecessary piece of glass.

Methods suitable for cutting plexiglass

The easiest way, without further ado, is to take a regular hacksaw for metal and make a neat cut according to the markings. You can use a grinder (if you know how to handle it).

If you need to perform shaped cutting, you will have to get sophisticated: a nichrome thread is connected to a 24-volt transformer, voltage is applied to it, and it burns a path of the desired shape in the plexiglass.

How to cut tempered glass

The only difference in processing regular and tempered glass is the fragility of the latter. The method with a grinder and a diamond disc is suitable, but you need to work extremely carefully. The method with a soldering iron may also be useful (depending on the thickness of the material), and the trick with water and scissors will definitely not work.

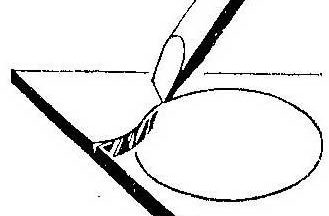

How to make a hole for a handle

There are several options - either drill using a drill with a pobedite nozzle, organizing a bath of plasticine with camphor and turpentine on the surface, or using the thermal method. To do this, apply fine wet river sand to the glass, and using a sharpened rod, make a funnel in it, into which molten solder or lead is dripped. After a couple of minutes, the sand and solder are removed.

Maybe someone will consider the list of methods incomplete - we have a lot of Kulibin methods, and there are many more options for solving the problem. But the advantage of the methods described, and in bold, is that they work.