DIY wood chipper

After cleaning, dry branches, roots, grass and other plant debris often remain in the garden plot. The question often arises: what to do with such waste? After all, the remains of trees, piled up, are an eyesore, and they take up a lot of space. And it’s not that it won’t work to burn them right away—it’s simply pointless. One way to productively get rid of them is to grind them into wood chips. Then, maybe, it will be useful for ignition or frying a kebab on coals (if the branch is thick), and in a pinch it will do for compost. To avoid large financial costs for factory units, you can make a branch chopper with your own hands.

The content of the article

Necessary materials

First you need to decide on the size of the structure and, of course, the engine. The choice largely depends on which branches are planned to be processedhow often and in what quantity.

Engine: petrol or electric

Each of them has its own advantages. So, gasoline has more power and is excellent for crushing large plant waste. It does not require power supply, so it can be moved anywhere in the garden. Its downside is that it spends a lot of fuel in fairly decent volumes.

An electric motor is inferior in power to a fuel motor, and its performance directly depends on the presence of a nearby outlet. But its weight is less than that of its gasoline counterpart, so transportation will be somewhat easier. Finding an electric motor will not be difficult, while for a gasoline one you will have to pay a good amount.

Frame design

The width of the frame is usually made about half a meter - it doesn’t make sense more. The height is determined depending on the height of the person who will use the unit. The length can be done, as they say, as God puts it in your heart. For structural rigidity, a transverse or diagonal strip is welded.

A small life hack: For ease of use, the shredder should be equipped with wheels.

Drive unit

The required power consumption is determined depending on the thickness of the wood. For processing branches up to 3 cm thick, an engine with a power of 2.5 to 3.5 kW is suitable.

Grass and thin twigs will be processed without problems by a unit with an indicator of 1.5 kW. The engine of a vacuum cleaner, grinder, and even some models of drills has this power.

Branches with a diameter of 3-5 cm can be powered by a 3-4 kW motor. This is exactly what a circular saw has.

Cutting mechanism

It is usually made up of several knives. You can make them yourself, for example, from high-speed steel R18. The classic option in this case is one-sided sharpening of the blades. You can give them, say, a diamond shape - quite practical.

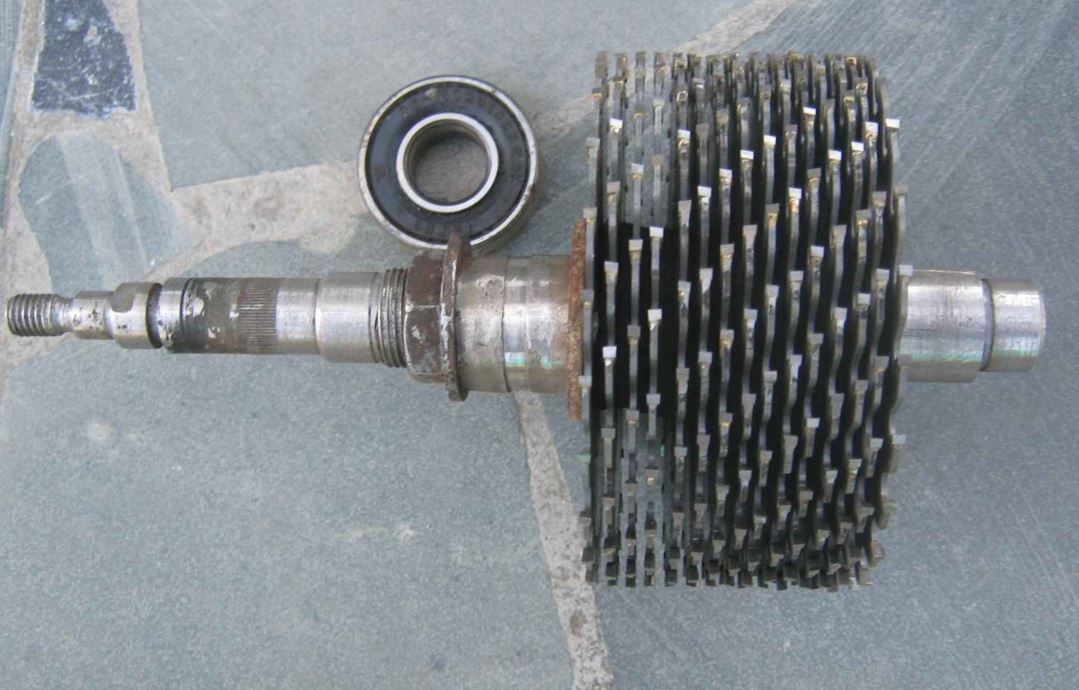

But why all this mouse fuss? If you decide to adapt an angle grinder for your purposes, you can take a circular disc for it and don’t further elaborate. An alternative is to attach a dozen circular saws or wood cutters to the electric motor shaft.

Bunker for disposal of recycled waste

It is attached to the bottom end of the housing. Recycled branches and grass are poured into it from the unit.

Having rummaged around the household and “scraped the bottom of the barrel”, you can probably find a sufficient number of elements suitable for homemade wood chip cutting. For example, metal corners, pipes, and channels are suitable for the frame. It is advisable to order some parts that need to be made on a lathe from professionals. To increase the torque of the crusher, you should use a flywheel mounted on the end of the shaft.

Crusher from washing machine

In fact, the washer is itself a storehouse of spare parts and hides in its depths most of the parts necessary for a garden shredder. Additionally, you only need knives and an extension cord. The motor of a washing machine has a small power - usually it does not exceed a kilowatt. Therefore, the crusher will be quite weak and suitable for grinding grass, straw and thin branches. There is no need to place any special hopes on her.

Sequence of the rework process:

- Trim the body to a comfortable height.

- At the bottom side, cut a hole with a grinder for a container for collecting crushed raw materials. This could be, say, a rectangle with dimensions 20*8 cm.

- Assemble the container itself, for example, from galvanized steel. You can select and adapt a ready-made container according to size.

- It would be necessary to make and attach legs, a stand or wheels to the structure. This is necessary to give it stability. And if you attach wheels, the problem of transportation around the site will be solved. The main thing is that it is not driven away by enterprising neighbors.

- Drill two holes with a diameter of 7 mm on the motor shaft. Place a bushing on it. The sleeve must have threads for bolts that will compress the knives on both sides.

- Place the knives on the shaft. Make sure that the fastening is secure - everything must be properly fixed, then there will definitely be no casualties.

- The electric motor is located in the lower part of the housing. To secure it, you can use bolts or studs with nuts.

- Inside the box, slightly above the hole for removing chopped plants, knives are attached to the shaft.

- The last step is to connect the extension cord. I think there shouldn't be any problems here.

Grinder grinder

This is the easiest and fastest way to build a branch chopper with your own hands. If you take a power tool with a power of 3 kW or more, the resulting crusher will be able to grind not only grass, but also branches with a diameter of up to 4 cm.

- Weld the stool frame. Make legs from steel corners and a shelf from a sheet of iron.

- Attach the grinder to the stool stand with clamps, shaft up.

- As a cutting mechanism, you can use a four-bladed trimmer disc or a circular disc with a large tooth.

- A large galvanized bucket with a pre-cut bottom is suitable for the protective casing. You can weld a similar structure yourself. The general principle, I think, is clear.

- Make a hole on the side, say 8*8 cm, and attach a sleeve to it through which sawdust will be unloaded.

- Now install the casing over the angle grinder and bolt it to the frame.

- Place a circular disc on the grinder.

Important! It is necessary to make the base stable and massive to avoid the device tipping over during operation.

You can place a bucket, barrel or any other container under the outlet hose for crushed products for easy collection.

The described models of wood chipper are not too difficult to make. The main thing is to have all the necessary parts on hand, otherwise you won’t be able to save money.But even if you have to spend money, the game is worth the candle.