How to sharpen a ceramic knife

Most users who prefer ceramic knives choose them for their convenience, sharp blade, and lack of the need for frequent sharpening. This type of knives dulls more slowly than their counterparts with a metal cutting strip.

Most users who prefer ceramic knives choose them for their convenience, sharp blade, and lack of the need for frequent sharpening. This type of knives dulls more slowly than their counterparts with a metal cutting strip.

The content of the article

Rules for sharpening a ceramic knife

Ceramics require careful handling due to the possibility of chipping, after which it is impossible to restore the blade. The ceramic knife should not be used to chop ice or frozen food in the freezer. It also does not withstand the bending that can occur, for example, when opening cans.

Although there is no need for frequent sharpening, it still occurs from time to time. As a rule, this happens 1-2 times a year. If you take care of the blade, it can last up to two years without sharpening.

Attention! When cutting food with a ceramic knife, you should not use ceramic or glass boards. Dropping it on a tile or stone floor may cause chips or complete splintering.

Ceramic blades are used for precise cuts, so most models are sharpened on one side. Universal blades with two wedge-shaped triggers are less common. Sharpening them is a more labor-intensive process.

How to sharpen a ceramic knife

To produce cutting strips, a ceramic alloy with zirconium dioxide is used, obtained at temperatures above 1500°C.In terms of hardness, zirconium ceramics is close to diamond. This big plus becomes a problem when choosing a method for sharpening a knife. According to the laws of physics, a hard material can be sharpened with the same or higher hardness index.

For ceramic knives, only diamond-coated tools are suitable. Today, there are several ways to sharpen zirconium ceramic blades:

- A special diamond-coated sharpener is a bar, the sides of which are strewn with crumbs of different grain sizes - large and fine.

- A manual sharpener is a device in which sharpening is done using discs. The tilt angle adjusted by the manufacturer protects the blade from damage.

- Electric diamond sanders are a professional tool for quick sharpening using two sharpening wheels. There is an adjustment option to adjust the strip thickness and inclination. Operates on rechargeable batteries or regular batteries.

- Sharpening machines - can be used by replacing a regular abrasive wheel with a diamond-coated disk.

- Musat is a device in which a diamond-coated hard metal rod is inserted into the handle. The rods can be cylindrical or polygonal.

- Diamond paste is an abrasive paste with a diamond grain size of no more than 5 microns. Not suitable for initial sharpening, used for final finishing.

Attention! When choosing a sharpener, you should pay attention to three indicators: the type of knives being processed, the sharpening angle, and the maximum thickness of the blade being processed.

Scheme for sharpening a ceramic knife

The scheme depends on the chosen method.

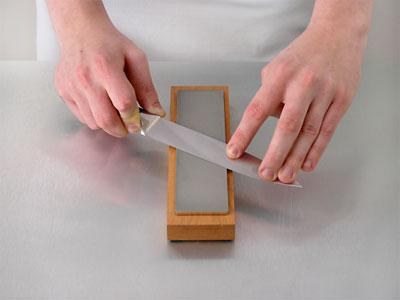

- Grindstone:

- 30 minutes before starting work, moisten the stone well;

- Carry out basic sharpening on the side of the block with a large coating without pressing hard;

- Position the blade perpendicularly, but taking into account the sharpening angle;

- If there are two wedge-shaped slopes, turn the blade over and make movements in the opposite direction;

- Turn the block over onto the reverse side with a fine coating and fine-tune the blade to perfection.

Reference! A diamond-coated sharpening stone must have a handle, without which the process is almost impossible for a user without skills.

Manual sharpener with discs:

- Place the blade into the slot;

- Using translational movements, move it “back and forth” several times;

- If you need to sharpen both sides, turn the knife over to the other side. Do the same manipulations.

Electric sharpener:

- Set blade angle and thickness options;

- Insert the blade into the slot on the device shaft;

- Turn on the device and move the knife 3-4 times in the “back and forth” direction.

Reference! An electric sharpener guarantees complete safety for the user from possible cuts and reduces the risk of knife damage to zero.

Musat:

- Place the grinder perpendicular to the table or with a slight slope;

- Without sudden movements, smoothly lower the blade from top to bottom and vice versa;

- Repeat the movement many times.

Reference! Musat is not suitable for sharpening dull blades. It is suitable for regularly maintaining the knife in excellent working condition.

Grinder:

- Install a disc coated with 80 microns for primary sharpening;

- Press the blade against the disk and carefully move it several times from the handle to the end of the knife. It is necessary to work at a low rotation speed, taking into account the manufacturer’s sharpening degree;

- Turn the blade over when sharpening on both sides. Repeat the operation.

- Change the disk to another one with a coating of 40 microns. Perform finishing and polishing.

Reference! The sharpening machine allows you to eliminate small chips on the blade.

Diamond paste:

- Cut out a piece of thick fabric (leather, tarpaulin) or cardboard;

- Apply a layer of paste on it;

- Grind evenly over a long period of time until the ceramic strip is perfectly smooth.

If you have absolutely no skills, it is better to sharpen a ceramic knife in a service workshop.