DIY hot smoked smokehouse

The smell of smoked food, lard, fish and sausage... An intoxicating aroma that just makes your mouth water and your stomach begin to rumble. The taste is simply amazing. But the price for these products is also amazing. Not every person can afford to enjoy hot or cold smoked dishes every day.

Their cost is still incommensurate with the volume of wallets of many of our compatriots. But why not refuse such a tasty treat? Of course not! You just need to make your own smokehouse. It is perfect for a private home or country house. But how to build it? We will try to figure this out.

The content of the article

Features of hot smoked products

And what kind of technology is smoking? What are its features?

Reference. This method of cooking has been known since time immemorial. Smoking refers to the heat treatment of foods. In this case, the heating of the product occurs not due to open fire, but due to smoke. In order for the technology to be followed correctly, you need to pay attention to the temperature, how much smoke is in the smoking chamber, how evenly the heating occurs and whether the product is enveloped in smoke on all sides.

Smoking has many beneficial properties, thanks to which it remains one of the favorite cooking methods. The positive properties include the following:

- all pathogenic microbes present on food products that can cause damage to our body are destroyed;

- smoking allows more nutrients to be preserved inside the product, which are destroyed under the influence of fire;

- food subjected to such processing can be safely stored for a very long time - the fact is that the smoke acts as a preservative.

The taste of the product directly depends on the wood chips, or rather on the type of wood from which the wood chips are obtained. Only at first glance it seems that the tree is simply burning, in fact, each of its varieties burns in its own way and has its own unique aroma. For each dish you need to select your own wood chips:

- Alder chips are well suited for meat and vegetable dishes;

- oak chips go well with pork or beef, and with all red meat;

- for bear meat, elk meat and venison, willow chips are used, and fish that live in swampy bodies of water are smoked on it;

- Various vegetables, berries and nuts are smoked on cherry wood chips.

What types of smokehouses are there for home?

There are many different options for smokehouses and they all differ in their design features. It all depends on what the user’s needs are and how well he knows how to build. But the most common are the following three types:

- shaft or vertical smokehouse;

- horizontal tunnel type smokehouse;

- chamber type smokehouse.

Vertical smokehouses are the simplest in terms of construction, and they do not require much space for installation. Outwardly, they look like a classic-looking hut, on the very top of which food is hung. There are some weaknesses in this design. The main disadvantage is the inability to smoke by fumigation, and the formation of smoke is difficult to regulate.

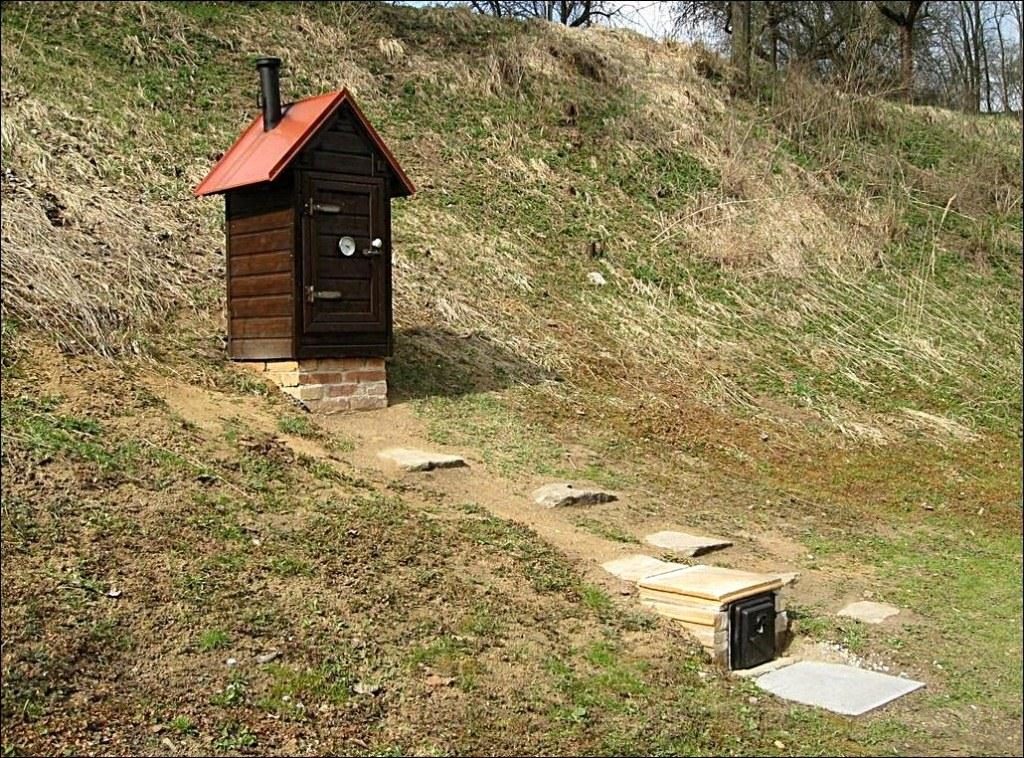

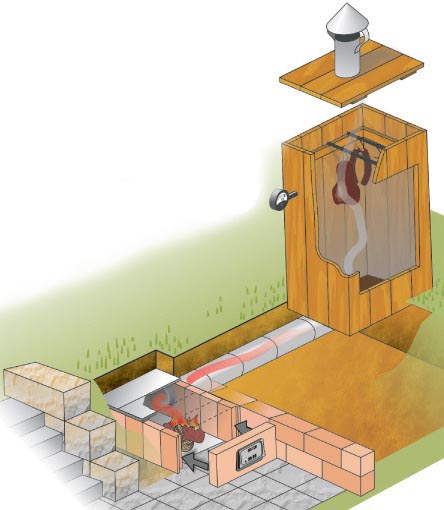

It will take much longer to build a horizontal smokehouse and require a lot of work with the soil. To install such a structure, you still need to find a convenient place - the slope of a ravine is best suited. The firebox is located inside a special chamber, which is of a semi-closed type. This allows you to smoke in different weather conditions. By changing the length of the chimney, you can make hot or cold smoked products.

The simplest design is for a chamber smokehouse. But despite this, it has considerable dimensions. It reaches a height of one and a half meters, and a meter in diameter. The main thing is to maintain the correct angle of inclination; it can range from ten to thirty degrees.

Construction of a home smokehouse and operating principle

Whatever size or shape you plan to make your smokehouse, in any case it must meet certain parameters:

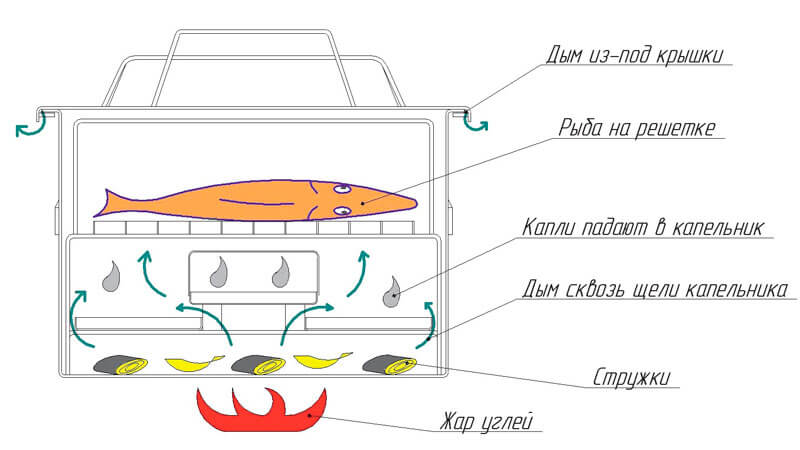

- it must contain a container or smoking compartment (products are placed or hung here);

- Naturally, the products need to be placed on something or hung by something, and therefore, a grate or even several are needed, or hooks;

- It is imperative to provide a collection of fat where it will drain from the product - fat should not fall on smoldering wood chips;

- You can do without a thermometer, but it makes it easier to control the temperature, so let it be.

How does all this work? Those products that are placed in the smoking chamber are enveloped in smoke on all sides.Smoke comes from smoldering wood chips. If we do hot smoking, then in addition to smoke we also receive heat treatment. After all, the smoke reaches a temperature of one hundred degrees.

Reference. Being surrounded by smoke, the products absorb its components, which gives a unique taste and aroma.

As with any process, hot smoking has its own rules that must be followed in order to obtain a product with excellent taste:

- the smoke should evenly envelop all products;

- there should be light smoke in the chamber, which contains a very small amount of harmful substances, this can be achieved by adding oxygen;

- the smoke must circulate well - this affects the speed of cooking and the taste of the product.

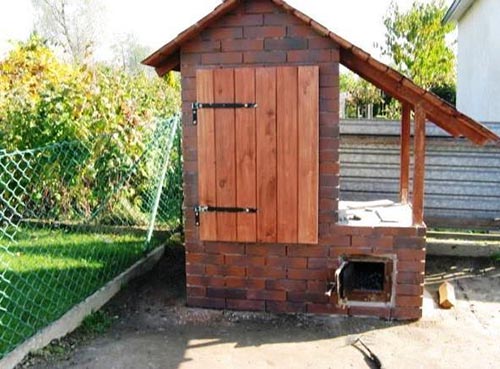

How to make a home smokehouse out of brick: drawing and photo

It is best to initially make a smokehouse with two chambers. Thanks to this, we can use different types of smoking at the same time. As soon as we decide on the place where our creation will be located, we will need to put the construction site in order. After this, we will definitely plan all future work.

We describe all the work step by step and draw a drawing by hand, marking all the necessary dimensions on it. In the plan we indicate what tools and devices will be needed for the work. These are the actual elements of the smokehouse, the type of brick and its quantity, doors, grates and a metal lid. In addition, we indicate the required material, which includes clay and foundation components.

Important! It should be remembered that ordinary masonry bricks are not suitable for a smokehouse. Be sure to purchase fireproof one.

If you strictly follow all the work technology, then your home smokehouse will delight you with appetizing and healthy dishes for a long time.When making masonry, each stage must be checked against the building level.

We carry out the work in the following order: first of all, of course, we make a base in the form of a foundation, after that we select a more suitable ordering scheme, and also decide how the smoke supply will be arranged.

Construction of the foundation

The foundation will be a cushion of concrete mixture, inside which we will lay a reinforcing lattice.

The technology for creating a foundation is simple. We dig a hole that will be larger than the smokehouse itself. The depth of the pit should be at least forty centimeters. We fill the bottom with sand and crushed stone. We lay a reinforcing mesh on top of them.

Before laying the mesh, we level and carefully compact the bottom layer. Fill everything with concrete solution and wait until it hardens. For waterproofing, we lay roofing felt.

We build a brick foundation

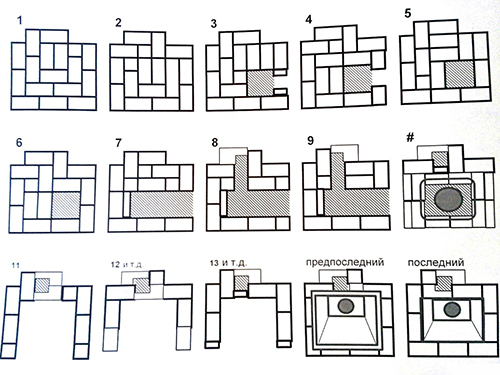

Our smokehouse is a fairly solid thing, so we should take the laying of bricks seriously. It is best to choose one of the proposed schemes for laying bricks.

As soon as we decide on the layout of the future structure, it’s time to start work: take a trowel and apply a mortar on top of the foundation base.

Advice. The mixture is prepared from fine sand and cement. We start from the fact that we have one part of cement and four parts of sand. Having mixed everything thoroughly, we begin to add water. At the same time, do not stop stirring until the mixture turns out thick. We apply the solution to the brick poker and place it vertically on the previously applied mixture. Then we gradually move towards the junction.

We continue to lay the brick, based on the diagram. Remove excess mortar from the bricks with a trowel. We make sure that the seams of the bricks do not coincide with each other.There must be a whole brick on the seam. This way our masonry will be stable and will not fall apart after a short period of time. Builders call this bandaging.

Making smoke supply

This is an indispensable attribute of the smokehouse if you plan to do cold smoking.

To do this, you first need to dig a trench. We make it fifty centimeters wide, thirty centimeters deep and the same length. We thoroughly compact the bottom. We lay the first row of bricks and fasten them with mortar. The vertical wall should be twenty-five centimeters in height.

At the top of the trench we make a house-type ceiling. Let the solution harden. When it completely hardens, we fill the trench with earth all the way to the smokehouse. The height of the earthen layer is approximately fourteen centimeters.

Important. Make sure that the chimney does not enter the smokehouse more than thirty centimeters.

First testing

Before we begin the permanent operation of our structure, we need to check it. During the check, all the “jambs” will immediately emerge and can be eliminated.

This is done in a simple way: pour sawdust into the desired compartment - it is better to use cherry or apricot. Let's make a fire. Place fish or meat inside. We close the chimney and wait a little until everything inside is filled with smoke. We wait until the thermometer reaches sixty degrees, after which we open the chimney.

Let it work for thirty minutes in normal mode. We extract our finished product. If the surface is golden and hot, it means we did everything right. We can praise ourselves and start preparing flavorful hams. Or other products.

Other options for do-it-yourself hot smoked smokehouses

If you don’t really want to engage in long and tedious construction, then you can adapt an ordinary two hundred liter barrel for a smokehouse. The volume can be changed both up and down, it all depends on your needs:

- First, we clean the entire barrel of paint; you can also clean it mechanically, but it will be much faster to do it with fire. You can throw the barrel itself into the fire or just light it inside. Let her burn for two hours.

- Now we make holes in the walls where the gratings will be installed. You also need to manufacture and install the inner glass.

- According to the diameter of the barrel, we cut out a lid from a sheet of iron, in which we make a hole for installing the chimney. In order for the lid to tightly close the barrel, you need to come up with weighting agents (for example, several bricks). It is better to use steel for the lid, but it can also be made from plywood.

If the barrel is made of wood, then the technology for its manufacture is no different, only between the inner metal glass and the outer casing you need to lay a material that is not afraid of fire and protects from heat.

Now we can install grates, fill in wood chips, and place our products. The barrel is heated from below over a fire or using a gas burner.

You can also make a smokehouse from a cylinder, but this is somewhat more troublesome. And all the gas needs to be released, the internal cavity must be thoroughly washed, after which you need to make a door. A hacksaw or jigsaw cannot cope with thick walls; here you will need an autogen.

Now you need to place the grates and tray inside the cylinder. The smoke itself will come from the outside.You will have to cut off its lower base in half. We weld a firebox from sheet iron and fix it under the cylinder.

Very often, old refrigerators serve as good homemade smokehouses. Anything resembling plastic must be removed from the unit. You won't need a freezer either. You can heat the wood chips with an electric stove. It should be placed at the very bottom, wood chips should be placed and turned on.