Do-it-yourself wooden cold smoked smokehouse

Few people will enjoy delicious and aromatic smoked meat or fish. Of course, you can purchase ready-made products in the store. But they are not comparable to what you can cook yourself.

For this you will need a smokehouse. You can make it yourself. To make a smokehouse, you don’t have to purchase expensive materials and spend a lot of time.

The content of the article

Advantages and disadvantages of a cold smoked wood smokehouse

To make smokehouses at home, wood is often used as a material. Such devices have their own advantages and disadvantages.

The advantages are:

- low cost of materials for manufacturing;

- simple preparation and assembly process;

- light weight of the finished product; if necessary, the smokehouse can be moved to any place;

- wood has excellent thermal insulation, which makes the smoking process stable;

- The materials used are completely environmentally friendly.

There are significantly fewer disadvantages of a wooden smokehouse:

- wood is not highly hygroscopic, so the smokehouse is afraid of high humidity;

- The finished smokehouse cannot be coated with varnish or paint.

Attention! In order for the product to last for many years, it is necessary to choose non-resinous hardwood as the manufacturing material. For example, beech or oak.

Design Features

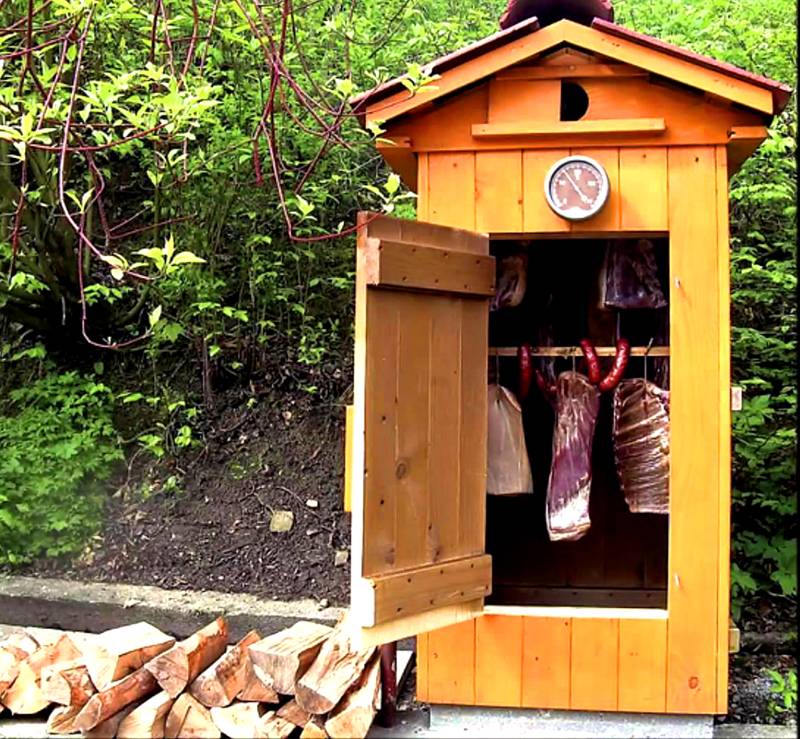

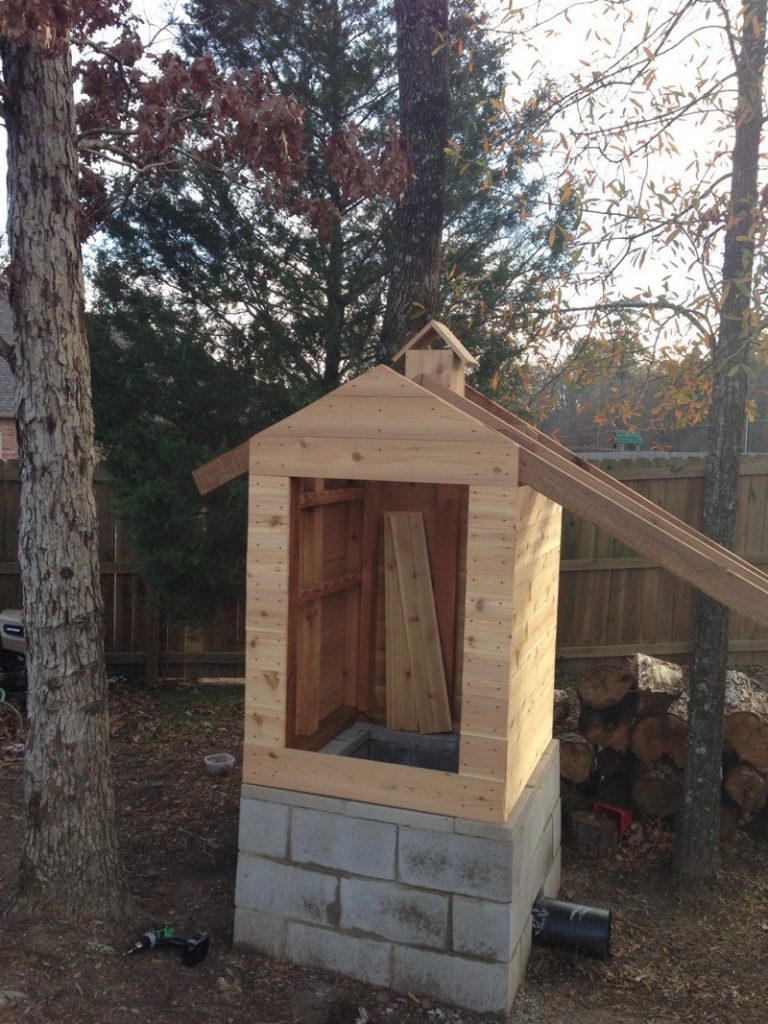

The main feature of a wooden smokehouse is its design. Such structures are made in the form of small houses.

The stove is located at some distance from the chamber and is connected to it by a pipe.

Important! The pipe and firebox must be completely sealed. This is required by fire safety regulations, since even a small spark can lead to a fire.

The pipe must be at least three meters long. Otherwise, the smoke will not have time to cool to the required temperature.

The chamber is equipped with hooks or brackets. Products will be placed on them.

Do-it-yourself wooden cold smoked smokehouse

A wood smokehouse is quite simple to make, has a pleasant appearance, is absolutely safe, and if high-quality materials are used and properly executed, it can last for many years. To build it you will need the following materials and tools:

- Not resinous wood. You can use: birch, alder, oak, linden or pine. You can also use plywood of sufficient thickness, clapboard, or small blocks. The material must first be impregnated with an antiseptic.

- Nails or screws.

- Sealant.

- Sheets of metal or corrugated sheets. They are necessary for making the roof.

- Temperature sensor.

- Fittings: hinges, door handle.

- Hammer, hacksaw, drill.

Algorithm for making a wooden smokehouse:

- The first step is to dig a hole of the required dimensions: depth - 0.5 m, width - 1 meter.

- Sand and crushed stone should be poured into the hole.

- Bricks should be laid along the perimeter of the pit and filled with cement mortar.

- Lay out a low base from bricks and place a connecting pipe in it.

- A small recess should be made at the end of the pipe. Then lay out the floor and walls with bricks. The walls must be located above the pipe.

- Make a firebox door. The top of the door must be covered with bricks or a slab. First, a sheet of metal should be laid under them. All gaps and joints must be carefully treated with a special composition for ovens or refractory clay.

- Next, you can begin making the camera. For convenience, it is better to do this at the place where it will be installed. First you need to make a frame. Then nail the prepared boards to it.

- You need to install a chimney in the roof and then sew it up.

- In the chamber you need to make fasteners for the hooks on which the products will be placed. The grooves can be made from a board of suitable size, giving it the required length and width. The board needs to be sawn, and then holes with a diameter of about 4 cm must be drilled in it. The prepared products should be placed on the walls of the chamber in several rows.

- The next stage is assembling the door. It needs to be assembled and hung on pre-placed loops. You need to secure the handle and latch to the door. All cracks must be sealed with sealing material.

- The roof is being made. It can be gable or single-pitch. If the first option is chosen, then triangles must be made from the blocks. These will be the guides. They should be secured with screws or nails to the top of the frame. Then you need to nail the boards onto the guides and sheathe the resulting structure with iron.When making a pitched roof, guides are not required - the boards are nailed close to each other. The pipe needs to be brought out through the roof.

- You need to install a “fungus” on the pipe.

- To ensure better thermal insulation, the resulting structure must be sheathed with clapboard.

- All cracks should be plugged with tow.

- The joints on the roof are treated with sealant.

- You need to install gratings on the prepared grooves. The distance between them should ensure good air circulation.

- A temperature sensor must be installed on the wall or doors of the smokehouse.

Attention! The required temperature for smoking is from 90 to 120 degrees. Since this is a fairly high temperature, there is a risk of fire. It is extremely important to follow fire safety regulations. Therefore, it is advisable to place a fire extinguisher or a box of sand next to the smokehouse.

A cold-smoked wooden smokehouse has many advantages. Anyone with minimal carpentry experience can do it themselves. The monetary and time costs are small. At the same time, the quality of the resulting products will exceed any store-bought analogues.