How to connect a boiler to a boiler

Today, many, especially owners of private households, are concerned about the availability of hot water in their homes. It is an integral part of comfort, practicality and convenience. The issue of ensuring uninterrupted hot water supply is solved in various ways. The most popular is the so-called indirect heating boiler (IH). According to the technical specifications, this option is more convenient to use when compared with flow-through heaters.

Today, many, especially owners of private households, are concerned about the availability of hot water in their homes. It is an integral part of comfort, practicality and convenience. The issue of ensuring uninterrupted hot water supply is solved in various ways. The most popular is the so-called indirect heating boiler (IH). According to the technical specifications, this option is more convenient to use when compared with flow-through heaters.

The content of the article

How does a boiler connected to a heating boiler function?

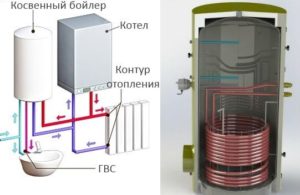

An indirect heating device from the outside is very similar to a storage device that runs on electricity. But, for the operation of the BKN, a heating boiler is required. The operation of an indirect heating heater is based on the principle of a thermos. Its contents, i.e. water, are heated by a heat exchanger located inside. Due to the fact that there is no direct heating, the water heater is called indirect.

An indirect heating device from the outside is very similar to a storage device that runs on electricity. But, for the operation of the BKN, a heating boiler is required. The operation of an indirect heating heater is based on the principle of a thermos. Its contents, i.e. water, are heated by a heat exchanger located inside. Due to the fact that there is no direct heating, the water heater is called indirect.

When the heating device is interfaced with the BKN, any coolant circulates, which leads to heating of the water in the latter. The movement of water occurs through two pipes - one that supplies and one that returns.The supply pipe evenly supplies hot water to the radiators and boiler. After passing through the boiler, the water returns through the return pipe to the boiler. It turns out that the contents of the boiler are heated like a battery.

The advantages of BKN are:

- high power and high efficiency;

- independence from electricity;

- various options for heating sources.

REFERENCE! BKN are wall-mounted and floor-mounted. If the boiler is large in volume, then it can only be floor-standing. Water heaters placed on the wall must be mounted strictly vertically. An unevenly secured boiler can create problems during operation.

The water heated in the heater can be consumed as needed simultaneously from different taps in different rooms.

IMPORTANT! The quality of the boiler has a direct impact on how quickly the water heats up - the better it is, the faster the process goes.

The temperature of the water inside the heater is always close to the degree of heating of the coolant circulating in the coil. If the boiler temperature is set to maxs +50°C, then the water in the tank will heat up to +50°C, no more. If you need the contents of the tank to heat up more, you can purchase a combination water heater. It differs in that, in addition to the coil that heats the water, it has a heating element, which raises the temperature to the intended level. Combined water heaters are a good fit for solid fuel boilers because the water continues to be warm when the fuel has already burned out.

There are water heaters both equipped with built-in control and without it. If there is control, the boiler can be connected to a heating system that includes boilers without control.The boiler is equipped with a temperature sensor and independently controls the movement or shutdown of hot water passing through the coil. To activate the operation of such a device, it is necessary to connect the supply and return pipes from the heating to the appropriate inputs. Next, you should supply cold water to the upper outlet and take care of connecting hot water. After this, the tank is filled and the water is heated.

Indirect heating devices are most often installed with automated boilers. Each manufacturer includes instructions with the water heater with diagrams for the correct installation of the device. They can also be connected to non-volatile boilers, but this requires special circuits and appropriate instructions.

BKN can work in conjunction with dual-circuit or single-circuit heating devices.

Connecting the heater to a dual-circuit device

For operation in small houses, as a rule, a double-circuit boiler is used. It is installed in close proximity to the place where water is used to avoid large heat loss.

For operation in small houses, as a rule, a double-circuit boiler is used. It is installed in close proximity to the place where water is used to avoid large heat loss.

Connection to a double-circuit boiler is carried out in several stages:

- choose the right place and install the heater (if it is suspended, secure it properly);

- correctly connect devices and combine them into a single system;

- to plug.

The boiler and the boiler are installed at a short distance from each other and are connected by an automatic device. This connection requires a circulation pump.

ATTENTION! The water heater must be connected to either a gas or solid fuel heating device.When working with an electrical device, the boiler will take on most of the electricity. As a result, there will be problems with heat.

Connecting a heater to a single-circuit device

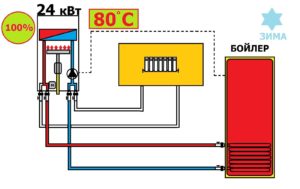

To provide hot water supply (DHW) to large, two-story houses, houses with a boiler room on the street, only a single-circuit boiler with a boiler is suitable. DHW will cost much more, but in this matter, saving is not the best solution.

To provide hot water supply (DHW) to large, two-story houses, houses with a boiler room on the street, only a single-circuit boiler with a boiler is suitable. DHW will cost much more, but in this matter, saving is not the best solution.

The BKN is installed behind the heating boiler. This is due to the fact that when the coolant is heated, more +90°C, there is a serious thermal load. It is better to make this piping area from steel or copper. The process of piping the water heater must be carried out in accordance with the procedure presented in the manufacturer's instructions.

The heater and boiler are connected using two pumps. The water is accordingly distributed into two pipelines. The presence of a check valve in front of both pumps ensures that flows of different heating do not change each other’s performance. Hot water is only available from the boiler.

General recommendations for connecting a boiler

When buying a boiler, you need to base your choice on previously obtained calculations from specialists:

- about the area of heat exchangers;

- thermal capacity of water;

- coil lengths and configurations;

- about current consumption (if a heating element is installed).

When connecting the heater, please note:

- when choosing the volume of the boiler, keep in mind that there are about 20 liters of water per person;

- To prevent the boiler from breaking due to electrical pressure changes, there must be a protection device and grounding;

- if the boiler is connected directly to electricity (without using a socket), high-quality sealing and non-flammable wires are used;

- a hydraulic accumulator must be placed at the point where hot water exits to absorb water shocks and compensate for thermal expansion;

- the socket should be located near the boiler, in case the heating is turned off (in this case, you can use the heating elements of the boiler for heating);

- install taps on the supply and return pipes to turn off the boiler in case of repair work (the heating will continue to work);

- In order to heat up faster, it is necessary to fix the boiler above the level of the radiators.