How does an indirect heating boiler work?

It is difficult to imagine comfortable living conditions in the 21st century without hot water supply. Constant interruptions in the work of public utilities force us to increasingly experience discomfort. The use of boilers for heating water solves this problem. The presence of autonomous communications in an apartment or private household allows you to use the heating system to prepare hot water using an indirect heating boiler.

The content of the article

Design features and operating principle of BKN

A boiler or heater is a tank designed to increase the temperature of water in an apartment or house. It is a barrel-shaped or rectangular container. Heaters are made of metal or heat-resistant plastic. There are several types of such equipment:

- direct heating;

- indirect;

- combined.

Direct type boilers heat water using an energy source: electric heating element or gas. Indirect heaters work due to the heating system. Combined ones have two methods of heating water. This is convenient when using the equipment all year round. In winter, hot water is prepared using an indirect heat exchanger, and in summer using a heating element.

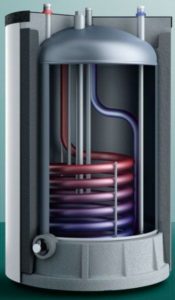

Water heaters are made of heat-insulating materials, which allows maintaining the temperature of the treated water for a long time. Unlike direct-type boilers, the internal cavity of indirect boilers is equipped with a coil.Coolant is supplied to it from the heating element (boiler) of the heating system.

How does an indirect heating boiler work?

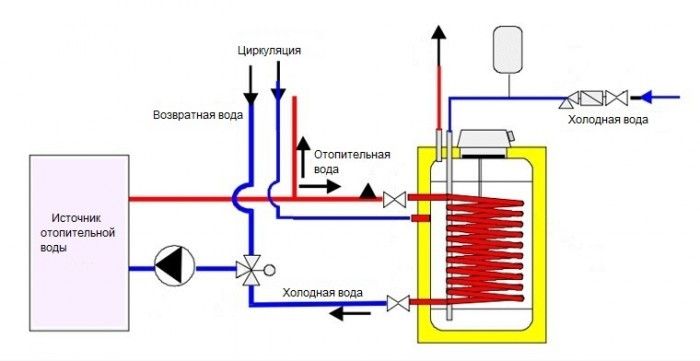

The heat exchanger installed inside the heater is the heat source for preparing hot water. The heating circulation pump constantly supplies coolant to the coil in a closed circuit. The water in the tank heats up quickly because the heat exchanger spiral occupies most of the internal space of the tank.

Using pipes, the tank cavity is connected to the cold and hot water supply lines, and the coil is connected to the heating system. The spiral is made of brass or steel for greater heat transfer. Hot water is drawn from the top of the tank.

Using pipes, the tank cavity is connected to the cold and hot water supply lines, and the coil is connected to the heating system. The spiral is made of brass or steel for greater heat transfer. Hot water is drawn from the top of the tank.

The heat supply is controlled using valves installed on the connected networks and a heating pump. When you open the supply and return taps connected to the boiler, the heat exchanger begins to heat up. Water is supplied and withdrawn to the heater in the same way.

IMPORTANT. Installation of input and output connections to utility networks is carried out in accordance with the requirements of the equipment manufacturer. Changing the order when connecting the pipes will not allow the heater to operate in the desired mode.

Cold water is supplied to the boiler. The heat exchanger carries out heating, after which, thanks to the pressure of the main line, hot water is supplied to the consumer. Depending on the temperature of the heating system coolant, different levels of heating of the consumed water will be provided. The simplicity of the design of the indirect type heater allows it to be used for a long period of time.The absence of intense heat sources contributes to minimal maintenance requirements.

Types and model varieties of equipment

There are indirect type boilers that heat water only using a heat exchanger. But there are a large number of models equipped with heating elements for using the heater in the summer. These modifications are convenient for home use and are in great demand.

There are indirect type boilers that heat water only using a heat exchanger. But there are a large number of models equipped with heating elements for using the heater in the summer. These modifications are convenient for home use and are in great demand.

These models are divided by installation method:

- Wall-mounted – the heater is attached to the wall using brackets. Such a boiler is usually made up to 200 liters. The possibility of installation under the ceiling expands the possibilities of free space under it.

IMPORTANT. The choice of fasteners and location should provide reliable support for the installation of equipment. Not every wall can withstand 250-300 kg of lateral load.

- The floor-standing version can heat a larger amount of water - up to 1000 liters. Requires dedicated space or installation in a separate utility room.

Boilers are also distinguished by the shape of the tank:

- horizontal - has greater capacity and takes up a lot of space;

- vertical - takes up little space, but I would like to increase the internal volume.

An important characteristic that allows the consumer to measure the capabilities of the boiler is the capacity of the heated water. The model range provides for the production of indirect type heaters from 75 to 1 thousand liters. Depending on the required amount of heated water, equipment is selected.

An important characteristic that allows the consumer to measure the capabilities of the boiler is the capacity of the heated water. The model range provides for the production of indirect type heaters from 75 to 1 thousand liters. Depending on the required amount of heated water, equipment is selected.

Another characteristic of indirect boilers is the thermal power of the heat exchanger. The value of this indicator takes into account the rate of heating of water at different coolant temperatures.

Pros and cons of the device

Any equipment has its positive and negative sides.

Let's look at the advantages first:

- long service life due to the simplicity of the design;

- no energy consumption when using the heating system;

- fast heating due to the fact that the power of the heat exchanger is several times higher than the power of electric heating elements;

- possibility of installing an additional electric heating element for all-season use;

- high water heating performance.

Now let's touch on the disadvantages:

- dependence on heating operation; when it is turned off, the indirect properties of the heat exchanger become unclaimed;

- the cost of boilers is very high, so not everyone will allow such pleasure in their abode;

- Floor-standing design takes up a large amount of space.

Considering the constant need for hot water, it makes sense for owners of autonomous heating to think about the possible purchase of an indirect water heater. Overcoming the price barrier will pay for itself in 2-3 years, due to the lack of costs and comfortable use of the equipment.