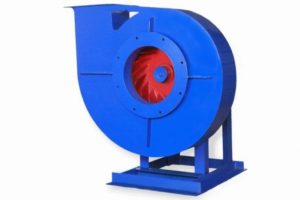

Industrial exhaust fan

Ventilation is forced air exchange in a room in order to create favorable conditions for humans. An industrial exhaust fan is designed to remove exhaust air outside the room through special air ducts. It is suitable for production facilities, warehouses, supermarkets, food factories, agricultural facilities, offices and cottages with a powerful ventilation system.

Ventilation is forced air exchange in a room in order to create favorable conditions for humans. An industrial exhaust fan is designed to remove exhaust air outside the room through special air ducts. It is suitable for production facilities, warehouses, supermarkets, food factories, agricultural facilities, offices and cottages with a powerful ventilation system.

The content of the article

What is it intended for?

An industrial exhaust fan is one of the elements of the climate system. It is suitable for supply, exhaust and supply and exhaust mains. The equipment can operate in one of two modes: pumping or pulling air flow, depending on which direction the blades are directed. The performance and efficiency of the system as a whole will depend on the correct calculation of performance and selection of the type of device.

Important! An industrial fan must remove from the workshop gases, fumes and toxic substances that are dangerous to humans and arise during production processes.

Tasks of industrial ventilation equipment

An industrial fan is installed at industrial facilities to increase the efficiency of air exchange. It is much more powerful than its household counterpart, so it is suitable for ventilating large areas. A wide range of cooler types and configurations allows you to select equipment for ventilation systems of any complexity. Industrial models are designed to solve the following problems:

An industrial fan is installed at industrial facilities to increase the efficiency of air exchange. It is much more powerful than its household counterpart, so it is suitable for ventilating large areas. A wide range of cooler types and configurations allows you to select equipment for ventilation systems of any complexity. Industrial models are designed to solve the following problems:

- local removal of metal and wood shavings, dust from the working surface of machines;

- removal of flue gases, injection of steam into the boiler room;

- local removal of dust and slag during welding work;

- intake of dusty air during production processes with increased dust formation;

- general air exchange in a large area in accordance with sanitary standards;

- transportation of grain by air flow, including the removal of processing waste.

What parts do industrial duct fans for ventilation consist of?

The main structural elements of a fan include a housing and an electric motor, which runs a turbine consisting of many blades (impeller). They have low aerodynamic drag.

The flow rate and efficiency depend on the power of the electric motor. Exhaust smoke removal coolers are introduced as an additional component of the climate system. They are subject to increased demands on performance and reliability.

How does an industrial hood fan work?

The fan power is determined by the rotation speed of the impeller.The size of the blade ranges from several tens of centimeters to several meters, depending on the type of equipment. The turbine is made of high-quality plastic, stainless steel or aluminum alloys. It is quite light, so it does not require large amounts of electricity to rotate.

The fan power is determined by the rotation speed of the impeller.The size of the blade ranges from several tens of centimeters to several meters, depending on the type of equipment. The turbine is made of high-quality plastic, stainless steel or aluminum alloys. It is quite light, so it does not require large amounts of electricity to rotate.

In most models of industrial devices, the power does not exceed 800 W. The units are connected to a 220 V power supply or a three-phase network, depending on the type of cooler.

Classification of industrial exhaust fans

Industrial fans are distinguished by the type of mounting and equipment design. There are models for local cleaning of workplaces and general air conditioning. Exhaust models are suitable for supply and exhaust systems, as they provide air inflow and outflow; they differ in the type of fastening.

By type of fastening

Window models are installed into a window opening or window. They are low noise, light weight and small in size. A check valve is installed on the outside of the cooler to prevent air from entering the room. Industrial devices are connected to a three-phase network.

Window models are installed into a window opening or window. They are low noise, light weight and small in size. A check valve is installed on the outside of the cooler to prevent air from entering the room. Industrial devices are connected to a three-phase network.

Floor-standing appliances belong to large-sized installations on wheels. The fan can be easily moved around the area. The unit does not require a permanent connection to the air duct. The inclination is adjusted using handles.

Duct fans are suitable for ventilation and air conditioning systems with ducts having a round, square or rectangular cross-section. They are installed directly inside the exhaust duct.

Ceiling coolers are suitable for buildings with high ceilings. They are introduced into air conditioning systems to uniformly equalize air temperature. They are compact, low noise, and do not interfere with the design of the room.

By equipment design

Axial models for hoods are a wheel in a cylinder that rotates. Such devices are sold in standard sizes or made to order for any ventilation systems. Coolers are used in many areas of activity. They are installed into the ventilation duct quite simply and do not require frequent preventive maintenance.

Radial models are characterized by increased productivity. They are designed to remove flue gases and toxic substances. These include devices of the “snail” type. As the turbine rotates, air flow enters the rotor. Gradually rotating inside the housing it comes out of the device. In this case, the air stream is cleaned of foreign impurities.

What are radial fans for hoods (industrial)?

Radial fans are capable of moving large volumes of air masses. They got their name due to the arrangement of spiral blades. The impellers are bent forward or backward. The movement of air in the housing occurs due to the centrifugal force, which is created inside the rotor with the help of working blades. There are roof and duct models. The ventilation intensity is controlled by changing the voltage supplied to the electric motor. The range includes high and low pressure devices.

Radial fans are capable of moving large volumes of air masses. They got their name due to the arrangement of spiral blades. The impellers are bent forward or backward. The movement of air in the housing occurs due to the centrifugal force, which is created inside the rotor with the help of working blades. There are roof and duct models. The ventilation intensity is controlled by changing the voltage supplied to the electric motor. The range includes high and low pressure devices.

Roof fans are installed outside the premises, so they do not violate the integrity of the interior and save internal space in the room. They are mainly used for smoke removal. The visor on the cooler prevents water from getting inside the case. Channel models are represented by classic snail-type coolers, centrifugal and dust models.

What should you know before installing an exhaust fan in an industrial building?

The fan is selected in accordance with the type of ventilation - for injection, exhaust or combined action, as well as the diameter, configuration and location of the ventilation duct. When choosing a specific model, you must consider:

- area and volume of the room, its architectural features;

- number of air ducts, their configuration, temperature conditions;

- the length of time it must operate;

- number of workers, workshop workload and location of workplaces;

- Features of equipment operation that affect air quality and microclimate.

Important! When calculating the need for fresh air, take into account the influx of clean air in an amount of at least 20–30 m2/h per 1 person.

It is recommended to install filters in the ventilation ducts, which will allow for less frequent preventive cleaning of the air duct. Dampers with direct or electric drive are necessary to block some parts of the air duct in order to limit the backflow of air flow. To heat air masses, air heaters are additionally provided.

Popular companies producing industrial exhaust fans for business

The assortment includes fans of domestic and imported production. Models differ in the presence of various additional options, so they are perfectly integrated into air conditioning systems. The Shuft brand offers window and axial coolers that are silent in operation and easy to install. The manufacturer occupies a leading position in the production of industrial models.

The assortment includes fans of domestic and imported production. Models differ in the presence of various additional options, so they are perfectly integrated into air conditioning systems. The Shuft brand offers window and axial coolers that are silent in operation and easy to install. The manufacturer occupies a leading position in the production of industrial models.

The “Mess” model range is distinguished by its durable metal body made of high-quality steel and low noise.The TYWENT brand represents a wide range of industrial and domestic fans of various types. Manufacturers "SAMA" and "SAVIO" offer rooftop models, high-pressure washers, pressure coolers, and radial fans. The “Dospel” line includes household and industrial appliances, including overhead models.