Ventilation tube

The content of the article

- What requirements must ventilation pipes meet?

- Characteristics of pipes for ventilation systems by their cross-section

- Plastic ventilation pipes

- Metal ventilation pipes

- Straight-seam and spiral-flow pipes for ventilation, their originality

- Insulated ventilation pipes

- Textile ventilation pipes

- How to calculate the required diameter of ventilation pipes

- Features of installation of ventilation pipes

What requirements must ventilation pipes meet?

The problem of ensuring ventilation and creating a healthy microclimate arises especially acute during the construction of a country house or cottage. Manufacturers today offer a large selection of a wide variety of pipes used in the construction of a ventilation system. In order not to make a mistake in choosing, you need to consider what functional properties are important for them.

The problem of ensuring ventilation and creating a healthy microclimate arises especially acute during the construction of a country house or cottage. Manufacturers today offer a large selection of a wide variety of pipes used in the construction of a ventilation system. In order not to make a mistake in choosing, you need to consider what functional properties are important for them.

Good ventilation ducts are valued for:

- maximum tightness;

- creating minimal noise during use;

- sufficient spaciousness in which air masses do not stagnate;

- thermal insulation of materials, allowing not to influence the temperature in the premises;

- ability to combine with the interior.

Let's take a closer look at their features and properties.

Characteristics of pipes for ventilation systems by their cross-section

Externally, the difference between the products is immediately noticeable, depending on whether they have a round or rectangular cross-section. Ventilation that provides air inflow or outlet, regardless of its draft, allows for both pipe configurations. The specific choice depends on the room parameters:

- For small rooms with low ceilings, a rectangular section is preferable.

- For large residential and industrial premises with high ceilings, a round section is more suitable.

Important! If a rectangular ventilation pipe is installed in a residential area, it must be additionally insulated. This will reduce the noise created when the air mass collides with obstacles in the form of corners.

Round pipes

- Size: The industry produces products of different diameters. Small diameters include diameters of 100 mm - 500 mm, large ones are considered to be 500 mm - 2000 mm.

- Straight connection length: 2.5 – 6 m.

Rectangular pipes

- Size: from a minimum of 100 mm x 150 mm to a maximum of 1600 mm x 2000 mm.

- Straight section length: maximum - 2.5 m.

Reference! The connection (as well as the routing or rotation) of rectangular and round air ducts is made with special elements that exactly correspond to the specific cross-sectional size.

In addition to the configuration, the properties of products depend on the material (plastic or metal) used in their production.

Plastic ventilation pipes

Types of plastic pipes

Air ducts made of plastic are becoming more and more popular. The material used, the presence of not only rigid but also bendable products allows you to design the necessary configurations, ensures noise reduction, and can be easily combined with the interior features.

A variety of polymers are used in their manufacture.

Plastic pipes and their characteristics

Plastics, PVC

Products made of plastic or polyvinyl chloride (PVC) differ from others in the lowest price, which is combined with absolute tightness, low noise levels, environmental friendliness and safety for people. The cross-section and shape of the products are varied, but installation is possible only in conditions that do not allow the material to be heated above 160°.

Polyethylene

Features of polyethylene ventilation pipes include antistatic properties, protection against ultraviolet radiation, black color, and high strength. They can be used under different temperature conditions. The pipes will safely withstand frosts down to - 40° and high temperatures up to + 80°.

Polypropylene

The advantage of polypropylene products is their wear resistance. They perform well at high humidity, easily tolerate aggressive environments, and are resistant to combustion. At the same time, they cannot be used at low temperatures, because frost causes polypropylene to become brittle and break easily.

Polyurethane

Polyurethane air ducts are very flexible. They provide quiet ventilation, tolerate heating up to 280° without releasing substances harmful to health, but cost more than other materials.

Fluoroplastic

A special polymer material, fluoroplastic, is characterized by super strength.Therefore, pipes made from it can be installed in rooms with different temperature conditions (from -40° to +140°); an aggressive environment with alkali or acid fumes will also not damage fluoroplastic.

Metal ventilation pipes

Metal is a traditional material used for air ducts before the advent of plastics. And nowadays, metal products for ventilation have not lost their attractiveness. They are distinguished by strength and reliability, good aerodynamics, and sanitary safety.

Metal is a traditional material used for air ducts before the advent of plastics. And nowadays, metal products for ventilation have not lost their attractiveness. They are distinguished by strength and reliability, good aerodynamics, and sanitary safety.

Types of metal pipes

In the production of ventilation air ducts, different types of steel sheets are used (galvanized, stainless, black steel), as well as aluminum. Various materials give products functional features.

Characteristics of metal pipes

Cink Steel

The thickness of galvanized air ducts is from 0.5 mm to 1.2 mm. Temperature range - from -40° to +80°. Thanks to the zinc layer, the products do not corrode, so they are used in places of high humidity. Not recommended in aggressive environments.

Stainless steel

Thickness: from 1 to 5 mm. Temperature range - from -40° to +500°. Resistance to various temperatures makes it possible to use stainless steel products in industrial production for ventilation of any premises, including aggressive environments.

Black steel

Thickness: 1.2 – 1.5 mm. Temperature range - from -40° to +800°. Products made of black steel are not particularly flexible, but are extremely durable. They are not afraid of high temperatures; the metal makes the products fire-resistant.

Aluminum

For air ducts, aluminum foil with a thickness of 0.55 mm is usually used. Temperature range - from -40° to +130°.

Aluminum air ducts are characterized by particular flexibility and lightness. They are characterized by antistatic, anti-corrosion, strength and tightness. A limitation of use is less resistance to high temperatures.

Straight-seam and spiral-flow pipes for ventilation, their originality

According to the production method, there are 2 types of metal ventilation products.

According to the production method, there are 2 types of metal ventilation products.

Straight-seam

Straight-seam air ducts are made of steel sheets. A blank of the required size, cut from a metal sheet. Then, on special machines, the sheet is rolled up, giving it the shape of a pipe, and then connected with a welding seam or a seam lock to ensure tightness.

Spiral filling

For spiral-filling products, it is not sheet metal that is used, but metal strip. The machine curls it into a spiral, creating a durable air duct.

Both production methods make it possible to produce reliable ventilation pipes with similar technical parameters.

Important! The production of spiral loading pipes is less expensive, since it does not require additional procedures for fastening the metal sheet. Therefore, such products are cheaper.

Insulated ventilation pipes

To increase wear resistance, ventilation air ducts with a diameter from 102 mm to 506 mm are subjected to additional insulation. It is made of a special protective coating that has several layers: plastic, special insulation - mineral wool, polyester, metallized aluminum foil.

Insulation increases the thickness to 2.5 mm. Insulation protects the head of the insulated duct in winter, providing additional sound insulation.

Textile ventilation pipes

Supply ventilation ensures the necessary supply and distribution of air into the room. For uniform distribution of air flows, textile air ducts, which have appeared recently, are used. Special technical textiles make them light and comfortable in everyday life.

Supply ventilation ensures the necessary supply and distribution of air into the room. For uniform distribution of air flows, textile air ducts, which have appeared recently, are used. Special technical textiles make them light and comfortable in everyday life.

They are easy to install or clean. They have antibacterial properties, are durable, resistant to humidity or chemical vapors, and perform well in temperatures from -40° to +280°. An additional advantage for residential premises is their decorative nature and variety of colors.

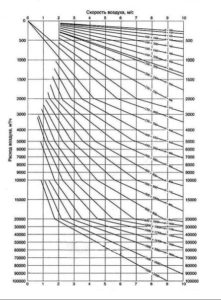

How to calculate the required diameter of ventilation pipes

When choosing an air duct for ventilation, it is necessary to consider what volumes of air must move through it. This will help calculate the required diameter, allowing air to move freely without forming stagnation.

To independently calculate the diameter of the air duct, you need to know the volume of air flow through.

Calculation algorithm

Determining the volume of the room - VTo - the area of the room multiplied by its height.

Determining the volume of the room - VTo - the area of the room multiplied by its height.- We determine how much air should move in 1 hour - n. To do this, we turn to special SNIPs, from which we learn:

- living quarters: 3 m³ per 1 m²;

- kitchens: from 60 to 90 (with a gas stove with 4 burners) m³ per hour;

- bathroom, toilet - 25 m³, combined bathroom - 50 m³ per hour.

- Finding the air exchange rate O=n x VTo.

- We determine the diameter using a special diagram.

Important! To calculate the diameter, you can use special programs that facilitate calculations.

Features of installation of ventilation pipes

You can install the air ducts yourself; it does not require special training.

Duct Installation Tips

Don't start fixing the ductwork right away. Pre-assemble it indoors, creating the desired configuration and determining the most suitable place for mounting.

Don't start fixing the ductwork right away. Pre-assemble it indoors, creating the desired configuration and determining the most suitable place for mounting.- The use of flexible products requires more than just pre-assembly of the product. The flexible air duct must be specially stretched. This will help prevent sagging of the excess length of the product.

- Remove excess by making final calculations taking into account the chosen mounting location.

- For reliable sealing, treat all joints with sealant before connecting them.

- Use brackets for mounting.

Important! When working with galvanized pipes, prepare in advance additional parts for fastening (angles, studs, nuts, bolts, etc.).