Overheated water in the heating system: why it happens and why a return pipeline is needed

Superheated water is a liquid in a heating system heated to a boiling point corresponding to a given pressure. This is a clear deviation from the norm, which a return pipeline helps eliminate. The coolant flows through it into the mixing chamber, where it connects with the direct flow and thereby cools it. The main causes of overheated water and ways to prevent this phenomenon are described below.

The content of the article

What does superheated water mean and why is it formed?

Superheated water in a heating system is a liquid heated to a critically high temperature, at which it can boil even under conditions of high pressure. Essentially, this is an emergency situation that can lead to an accident. In a central heating system, the coolant has the following temperature:

- 130-150 degrees at the hottest point (directly at the place of heating by the boiler at the thermal power plant);

- 110-120 degrees at the exit from the boiler room or thermal power plant;

- 95-105 degrees – at the entrance to an apartment building;

- approximately the same level should be in the radiators of each apartment (but not higher).

It is clear what kind of water is in the central heating radiators. In terms of temperature, it approximately corresponds to 100 degrees, i.e. this is essentially the boiling point. But in fact, the boiling process does not occur due to increased pressure.If even under such conditions the liquid begins to boil, it is already overheated water. The reasons for its occurrence may be:

- clogging of boiler filters;

- the formation of an air lock inside the pipe (for example, due to loss of tightness, improper repairs);

- low water flow rate due to malfunction of the circulation pump;

- clogging of heat exchangers, for example, scale formation;

- incorrect installation of individual elements of the heating system, for example, an elevator.

How to reduce the temperature of overheated water

This phenomenon is rarely observed in a central heating system, since the temperature in each area is automatically controlled. Obviously, to cool the water, you need to lower the temperature in the boiler or turn it off completely for a while.

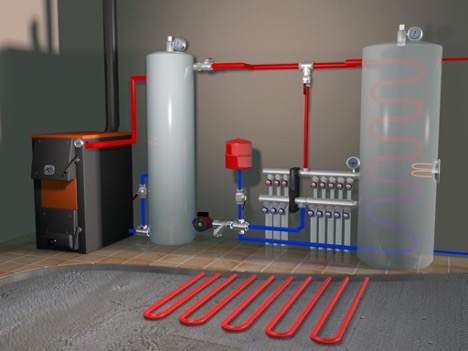

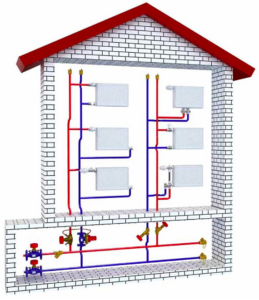

But this measure cannot be considered effective if the heating circuit lacks such an important element as a return pipeline and an elevator. The return pipe (return) drains water from the radiators after significant cooling by about 20-30 degrees. The minimum temperature should be 63 degrees, although 70 degrees or higher is common.

Moreover, the cooled liquid in the return line does not go into the sewer, but closes onto the pipe. The junction of the direct and return circuits is equipped with a special metal element - an elevator. As can be seen in the diagram, it ensures the connection of two coolant flows in the mixing chamber.

Moreover, water from the heating network enters through a narrowing device - a nozzle (shown in red). It not only ensures the mixing of two flows, but also increases the pressure. This difference is necessary to ensure a strictly defined rate of water circulation.Typically, elevators are installed only in apartment buildings. Heating in private houses is equipped with a circulation pump, which provides the required flow rate.