Do-it-yourself ozonator

Why make an ozonizer at all and what is it? Let's start in order. Ozone is one of the variants of the existence of oxygen in nature, consisting of a combination of three atoms. Under normal conditions it appears as a blue gas. It was discovered by the Dutch physicist M. van Marum in 1785 as a result of experiments on passing electric sparks through air. The term “ozone” (Greek: smell) was proposed in 1840 by the German chemist H. F. Schönbein.

The properties of ozone are such that when it decomposes, a large number of active oxygen molecules are released, which have a detrimental effect on pathogens, fungi, and viruses, promoting the speedy healing of wounds. To create ozone indoors, household appliances - ozonizers - were developed.

When assembling an ozonizer with your own hands, you need to remember that ozone is produced in three ways:

- In the case of passing through oxygen O2 powerful electric discharge is the simplest and most common method.

- In case of irradiation of O2 with powerful ultraviolet radiation.

- As a result of synthesis in the presence of catalysts, this is the least common method due to the high cost of chemical reagents.

The content of the article

- Scheme for making a homemade device

- Useful recommendations on how to make an ozonator correctly and quickly

- Safety precautions when making an ozonizer for your home with your own hands

- What is the difference between an ozonizer manufactured in an industrial environment and a home-made device?

- Pros and cons of homemade household ozonizers

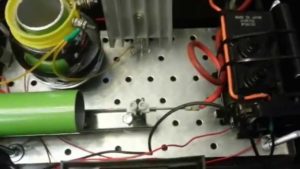

Scheme for making a homemade device

On the diagram

| Name | Denomination | Qty | Note |

| VT1 Bipolar transistor | KT805AM | 1 | |

| VT2 Bipolar transistor | KT361A | 1 | Denomination with any letter |

| R1 Resistor | 100 Ohm | 1 | 1–2 W |

| R2 Resistor | 56 kOhm | 1 | |

| R3 Resistor | 1 kOhm | 1 | |

| R4 Resistor | 260 Ohm | 1 | |

| R5 Resistor | 100 MOhm | 1 | |

| T1 Transformer | TVS110PTs16(TVS110PTs15) | 1 | From TV |

| У1 Voltage multiplier | UN9/27–1.3 | 1 | From TV |

| Voltage multiplier (self-assembly) | |||

| VD2–VD5 Diode | KTs105G(7GE350AF) | 4 | With eg. up to 8 kV |

| C2–C4 Capacitor | 320 pF | 4 | With eg. up to 20 kV |

Necessary tools and materials for creating a household ozonizer

Tools you may need are a soldering iron with tin and solder, pliers, a drill with a thin drill, small tools like a knife and tweezers.

Tools you may need are a soldering iron with tin and solder, pliers, a drill with a thin drill, small tools like a knife and tweezers.

In addition to a 220 V power outlet, you will need:

- voltage converter, there are many circuits for self-assembly on the Internet, you can choose whichever one you want;

- inductive coil;

- an emitter through which ozone will be created;

- housing, so that the emitter looks like a full-fledged device, and also so that it does not fit with your hand or any other part of the body where you should not get into.

All of the listed components can be assembled with your own hands if you wish, if you have skills in radio engineering.

If you don’t want to bother with the converter, a factory-made dimmer will do for this purpose.An ignition coil from a Zhiguli or Zaporozhets is suitable as an inductive coil; it will only need to be equipped with two capacitors with a capacity of 2 μF for 630 volts.

The emitter will need the following parts:

- two getinaks plates with dimensions 100X100X3 mm;

- four getinax strips with dimensions 100X10X4 mm;

- two aluminum plates 80X80X1 mm;

- glass 80X80X2 mm.

The plates serve as outer planes. In the central part there is glass, on top of which there are insulating strips on both sides. On top of them are aluminum plates with terminals. The result is a design with a gap between the plates, where ozone will be created due to the corona discharge. During assembly, contact between the aluminum plates should be avoided.

You will also need high voltage wires and insulators. The housing is assembled from available materials or purchased of a suitable size after successful testing of the device.

Sequencing

Before you start using the assembled device, you should ensure that it is working correctly. Firstly, a working device produces the characteristic sound of a working transformer, crackling. Secondly, during operation, a faint bluish glow should appear in the gap of the emitter. And thirdly, there should be a characteristic smell of ozone in the air.

Before you start using the assembled device, you should ensure that it is working correctly. Firstly, a working device produces the characteristic sound of a working transformer, crackling. Secondly, during operation, a faint bluish glow should appear in the gap of the emitter. And thirdly, there should be a characteristic smell of ozone in the air.

During operation:

- When processing the air in the room, the unit is turned on for 20–30 minutes, and you must leave the room.

- Upon return, the device is immediately de-energized and the room is ventilated.

- It is prohibited to use the ozonizer in damp rooms or those containing large amounts of conductive dust.

Important! It is necessary to exclude children from accessing the ozonizer.

Useful recommendations on how to make an ozonator correctly and quickly

If you have no experience as an electrician or radio technician, the most useful recommendation would be to go to a hardware store and buy a factory-assembled ozonizer. If everything is not so bad with skills, then before assembling the unit, you should familiarize yourself with the design of ready-made devices, and take a ready-made working diagram instead of reinventing the wheel. An ozonizer is a high-risk device, so it is better to learn from the mistakes of others than from your own. The time spent getting acquainted with ready-made, working devices will more than pay off.

Important nuances of assembling a homemade household ozonizer

The most important point is the assembly of the emitter. It is necessary to correctly select insulating materials, and also make sure that the aluminum plates of the emitter do not contact each other, otherwise a short circuit may occur with the ensuing consequences.

The most important point is the assembly of the emitter. It is necessary to correctly select insulating materials, and also make sure that the aluminum plates of the emitter do not contact each other, otherwise a short circuit may occur with the ensuing consequences.

It is mandatory that the finished device is mounted in a durable, non-electrically conductive housing. The question here is no longer about aesthetics, but about the safety of using the ozonizer.

An important nuance is the qualifications of the person collecting the ozonizer. It is strongly recommended not to assemble such electrical appliances by an amateur, otherwise things may not reach the point of improving the air quality - the person who assembled it will need to be restored to health.

Device installation rules

Installation is carried out in the following sequence:

- mains power supply;

- voltage converter with capacitor at the output;

- low voltage coil winding;

- Power is supplied via high voltage wires to the second capacitor, and then to the emitter.

Air is supplied forcefully to a vertically installed radiator by means of a fan.

Safety precautions when making an ozonizer for your home with your own hands

As already described above, assembly must be carried out by a qualified specialist, ideally an electrician with 4th approval group. General safety requirements should not be neglected:

As already described above, assembly must be carried out by a qualified specialist, ideally an electrician with 4th approval group. General safety requirements should not be neglected:

- Do not assemble the device or install individual elements when the power supply is turned on.

- Do not use faulty or uninsulated power tools.

- Avoid contact with wet surfaces and ozonizer elements at the same time.

- Use standard power tools.

- Do not use so-called “bugs” as fuses, that is, non-standard homemade fuses.

- Make sure that the socket and electrical wiring are in good working order and reliable.

What is the difference between an ozonizer manufactured in an industrial environment and a home-made device?

The differences between homemade devices and industrial ones are different for each specific case. It’s worth starting with the fact that a factory-assembled ozonizer is manufactured according to a specific, tested design and meets a number of requirements regarding operational safety. It also has the stated parameters - power consumption, performance, and is equipped with clear operating instructions and has a warranty period. However, its price can be many times higher than the cost of the elements used in the homemade device. And it is far from a fact that a factory device is superior in performance and reliability to a homemade one.

The differences between homemade devices and industrial ones are different for each specific case. It’s worth starting with the fact that a factory-assembled ozonizer is manufactured according to a specific, tested design and meets a number of requirements regarding operational safety. It also has the stated parameters - power consumption, performance, and is equipped with clear operating instructions and has a warranty period. However, its price can be many times higher than the cost of the elements used in the homemade device. And it is far from a fact that a factory device is superior in performance and reliability to a homemade one.

Pros and cons of homemade household ozonizers

The biggest advantage of making a homemade device is its low cost compared to its factory counterpart.Sometimes the difference in price can be not even several times, but tens of times. Further, with the right approach, you can assemble a device that is economical in terms of energy consumption, safe to use and productive. The third plus is complete freedom in terms of design. You can assemble an original, stylish and productive device, one of a kind.

Disadvantages - to assemble such devices yourself, you need a wealth of experience and theoretical knowledge. There are no declared parameters; everything is often selected experimentally. There is no factory warranty or operating instructions - the nuances of the device’s operation are also tested in practice.