DIY water boiler

When choosing a heating boiler among well-known and not so domestic and foreign manufacturers, you can easily make a mistake and buy a low-quality product at a huge price, so in such situations, it is quite possible to make a heating boiler with your own hands, at home using improvised means. At the same time, you can save money and spend it on something more valuable and important.

When choosing a heating boiler among well-known and not so domestic and foreign manufacturers, you can easily make a mistake and buy a low-quality product at a huge price, so in such situations, it is quite possible to make a heating boiler with your own hands, at home using improvised means. At the same time, you can save money and spend it on something more valuable and important.

The content of the article

How to make a heating boiler yourself

Making your own water boiler is quite simple. The most popular material for creating heating boilers today is sheet steel with a density of 5 millimeters. Fireproof stainless steel is best suited for this purpose; if the boiler is made from another metal alloy, it can quickly lose its ability. When making a boiler, it is important to take into account the future or existing method of circulating coolant in the heating system.

If it flows by gravity, you will need to raise the water tank as high as possible, and large-diameter pipes will be required for distribution. And not only on the supply side, but also on the return side.

Important! This is due to the fact that the resistance to the movement of the coolant is inversely proportional to the diameter of the pipes.If the size of the pipes is insufficient, then you will not be able to do without installing a circulation pump.

Necessary materials

As soon as you have finished counting the amount of materials, you can move on to design and installation. In order to begin assembling the heating boiler, you will need the following materials:

- Steel corners.

- Small metal grill.

- Door made of cast iron.

- Large metal sheet.

- Cast iron pipes.

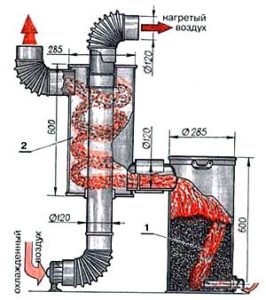

Water boiler diagrams

All boilers are divided into several different types, depending on the type of fuel used.

Wood boilers for heating

Wood-burning boilers are considered the most popular due to their fairly simple design and low price of the required materials. In addition, the type of fuel is considered the cheapest and most accessible. You can make such a boiler literally in one day, without putting a lot of effort into it.

Pyrolysis boilers

These boilers operate at high temperatures, in the range of 300-800 degrees, while burning wood, which, due to a lack of oxygen, decomposes into wood coke and pyrolysis gas. One stack of firewood will be enough for 12 hours, while for standard heating boilers this figure is three times less. Such boilers will not require a large amount of expensive material, and making it will not be a problem.

Waste oil heating boilers

The boiler is melted, put into operation and waste oil begins to flow onto a special heat-resistant tray, which evaporates literally in a matter of minutes, as a result of which the resulting combustion gases begin to heat the coolant and generate heat.In addition to used oil, you can also use diesel fuel, but this will be more expensive.

Electric heating boiler

A heating element inside the pipe, located vertically, the return is attached to the base of this pipe, and the supply is attached to the top.

Step-by-step instruction

Instructions with step-by-step steps for creating a boiler at home:

- You need to remove the valve from the old cylinder; for this you need to use a regular hammer.

- Next, in the upper part of the cylinder you need to make a cylindrical hole for the future door.

- Using the corners, you need to construct a frame on which the door will subsequently be attached. When the frame is ready, weld it to the cylinder.

- Make a small hole in the door and frame. It is best to go from the bottom of the structure and then attach the grate to the hole you made.

- Four identical strips of metal need to be welded to a piece of cut iron to form a box, but without a lid.

- The welded metal box must be attached to the bottom of the boiler. In the future, this box will serve as an ash pit.

- Also, metal legs need to be welded along the edges of the boiler so that the heat does not damage the floor covering.

- In the upper part of the entire structure, make a hole for the chimney and attach the chimney pipe.

Everything is quite simple and easy, and most importantly, it does not require a lot of time, effort and money.