Construction of a solid fuel boiler

Creating a warm, cozy microclimate in a country house during the cold season becomes possible thanks to the presence of well-chosen heating equipment. The use of solid fuel boilers is becoming more popular every year. This is due to rising prices for the resources used to operate heating systems. The availability of coal and firewood is displacing more expensive energy sources such as electricity, gas, and liquid fuels.

Creating a warm, cozy microclimate in a country house during the cold season becomes possible thanks to the presence of well-chosen heating equipment. The use of solid fuel boilers is becoming more popular every year. This is due to rising prices for the resources used to operate heating systems. The availability of coal and firewood is displacing more expensive energy sources such as electricity, gas, and liquid fuels.

The content of the article

How does a solid fuel boiler work?

The body of units for burning wood and coal is made of steel. It has a rectangular shape, and the dimensions depend on the thermal power. Like any furnace equipment, inside the frame from bottom to top there are: an ash pan, a combustion chamber, a water jacket, and in the upper part there is a pipe for removing combustion products.

The body of units for burning wood and coal is made of steel. It has a rectangular shape, and the dimensions depend on the thermal power. Like any furnace equipment, inside the frame from bottom to top there are: an ash pan, a combustion chamber, a water jacket, and in the upper part there is a pipe for removing combustion products.

Through the lower door of the unit, ash is removed, it also regulates the draft - and, accordingly, the thermal power of the boiler. The firebox is separated from the ash pan by grates, which are made of cast iron. Thanks to the use of such material, the service life of the grates is increased. The combustion chamber is equipped with a separate door through which firewood is loaded into the unit.

The use of different materials in the manufacture of water jackets divides solid fuel equipment into models:

- with cast iron heat exchanger;

- with a steel jacket.

The complexity of the design of heat exchangers depends on the functions assigned to the boiler, power and purpose. Units that have a large number of multidirectional passages of combustion products in the internal cavity of the jackets are equipped with special dampers. The opening or closing of these dampers regulates the air flow of hot masses during fuel combustion.

Some heating equipment manufacturers install cast iron burners on the upper surface of the body, which are used in everyday life for cooking. Such units are called stove boilers.

The outlet pipe for the chimney is equipped with a special damper, which is used to regulate the flow of hot air flows during combustion directed into the exhaust gas channel.

REFERENCE! There are models designed for heating baths. The top surface of such sauna stoves is designed to place stones that heat the air, and a heat exchanger heats running water for use.

How does a solid fuel boiler work?

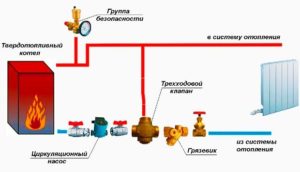

The principle of operation of wood-burning boilers is that, after loading fuel into the chamber, it is ignited and the firebox is closed. For combustion, air leaking through the grate is used. Under the influence of natural draft, hot flows of exhaust gases pass from bottom to top, along the cavities of the water jacket. Due to the high temperature of the combustion products, the heat exchanger heats up, and the smoke is removed through the outlet pipe - into the chimney.

The principle of operation of wood-burning boilers is that, after loading fuel into the chamber, it is ignited and the firebox is closed. For combustion, air leaking through the grate is used. Under the influence of natural draft, hot flows of exhaust gases pass from bottom to top, along the cavities of the water jacket. Due to the high temperature of the combustion products, the heat exchanger heats up, and the smoke is removed through the outlet pipe - into the chimney.

The use of dampers with which the unit is equipped allows you to regulate the combustion process. When the boiler is ignited, all dampers are opened, thereby providing access and removal of a large amount of air necessary for the operation of the boiler.As the firewood or coal burns, first close the ash pan damper, and after stabilizing the combustion, close the heat exchanger, ensuring the required movement of hot air masses through the internal cavity of the equipment. The damper on the chimney pipe is covered only when the closed ash pan damper cannot contain the increase in coolant temperature.

ATTENTION! Manufacturers of solid fuel units do not always provide the smoke exhaust pipe with a damper! In this case, the damper is installed on the chimney.

To maintain a constant combustion temperature, thermostats are used, which, depending on changes in coolant parameters, control the lower damper of the boiler. Install the regulator at the top of the water jacket. Due to the rigid connection, with the help of a lever and a chain, the position of the gate changes when the thermal head is turned, which reacts to fluctuations in the temperature of the coolant.

The design of most solid fuel units involves manual loading with firewood or coal. Manufacturers of modern equipment offer consumers models with automatic fuel supply. This technique is popular when using granulated briquettes, specially made for combustion during the preparation of the coolant.

Types of boilers according to operating principle

Burning wood or coal in the combustion chamber can occur using various methods. The use of one method or another divides solid fuel equipment into several categories.

Classic

The name itself speaks about the method of burning fuel that is familiar to furnace equipment. The firebox is loaded with wood, ignited, the door is closed and the air supply is regulated using a blower manually or with a thermostat.The hot air, rising, heats the water jacket of the boiler and exits through the chimney. The power of the classic unit is regulated by the air damper of the ash pan. But even with the gate completely closed, the combustion process will continue, only with less intensity.

The name itself speaks about the method of burning fuel that is familiar to furnace equipment. The firebox is loaded with wood, ignited, the door is closed and the air supply is regulated using a blower manually or with a thermostat.The hot air, rising, heats the water jacket of the boiler and exits through the chimney. The power of the classic unit is regulated by the air damper of the ash pan. But even with the gate completely closed, the combustion process will continue, only with less intensity.

This method is popular in the manufacture of low-power household boilers. Due to the simplicity of the design, craftsmen who independently manufacture a heating unit often resort to using this technique. The smooth surfaces of the internal cavities make it easy to maintain and clean the internal surface from ash and soot.

Long burning

The main disadvantage of using a solid fuel boiler is the need to frequently add firewood to the firebox. To increase the time interval between downloads, various technologies have been developed. One such method is called long-burning.

A feature of this method is the gradual layer-by-layer combustion of a large amount of stored fuel. Slowing down the combustion process is achieved by changing the directions of the flow of hot air masses in the internal part of the heat exchanger. Depending on the number of oncoming flows, long-burning units are:

- two-way;

- three-way;

- multi-pass.

Heat exchangers with a large number of strokes are used in high-power industrial boilers from 100 kW. Long-burning household equipment is made with a two- or three-pass water jacket.

Solid fuel mine-type units have found wide application in everyday life. The design feature of which is that the blower is located in the upper part, and the chimney originates at the bottom. Such boilers have one heat exchanger stroke from top to bottom.Combustion occurs in a direction unusual for the laws of physics, due to the opposite direction of thrust. The big disadvantage of such equipment is the constant need to clean the smoke outlet pipe located in the lower part of the housing. Due to the unusual direction of the work process, wood burning occurs very slowly.

In addition to long-burning boilers that use natural draft in a slow mode to increase the time intervals between fuel loadings, there are units with forced regulation of air flows using fans. The complexity of selecting equipment, and subsequently controlling the movement of hot air flows, makes boilers with forced movement of exhaust gases not very popular.

Pyrolysis

A type of long-term combustion is the division of the heat transfer process into the combustion of solid fuel and the afterburning of pyrolysis gas. The firebox of such boilers is divided into two chambers: in the first, the wood smolders slowly with a lack of oxygen, due to this, secondary gas (hydrocarbon, nitrogen, carbon monoxide...) is released, which burns in the second part of the combustion chamber.

A type of long-term combustion is the division of the heat transfer process into the combustion of solid fuel and the afterburning of pyrolysis gas. The firebox of such boilers is divided into two chambers: in the first, the wood smolders slowly with a lack of oxygen, due to this, secondary gas (hydrocarbon, nitrogen, carbon monoxide...) is released, which burns in the second part of the combustion chamber.

To slow down combustion in pyrolysis units, reverse draft is often used, similar to that created in a shaft-type unit. Or they use special smoke exhausters that regulate the movement of combustion products inside the heat exchanger. Air is supplied to the second combustion chamber for combustion of secondary gas. The internal cavity of such equipment has high aerodynamic resistance, which allows the fuel not to flare up in the first chamber.The working process in the second compartment burns all harmful gases, the formation of which is typical for normal combustion.

IMPORTANT! The operation of pyrolysis boilers does not allow the use of fuel with a moisture content above 30%! Excess moisture will interfere with the process of releasing secondary gases!

The double combustion process increases the efficiency of the solid fuel unit. The use of less wood or coal compared to conventional boilers makes the consumer think about the possibility of using such technology to heat their own home.

On pellets

Expensive equipment includes long-burning equipment that uses granular fuel as a resource. The complexity of the design is due to the presence of a hopper for loading and a mechanism for feeding pellets into the firebox. The amount of time (up to 7 days) of autonomous operation of the unit depends on the size of the loading container; it has the shape of a truncated cone, where there is a hole for connecting to a screw or other type of mechanism that portions the briquettes into the firebox, as needed.

Expensive equipment includes long-burning equipment that uses granular fuel as a resource. The complexity of the design is due to the presence of a hopper for loading and a mechanism for feeding pellets into the firebox. The amount of time (up to 7 days) of autonomous operation of the unit depends on the size of the loading container; it has the shape of a truncated cone, where there is a hole for connecting to a screw or other type of mechanism that portions the briquettes into the firebox, as needed.

The operation of all components and mechanisms of such a unit is controlled automatically. Modern models are even equipped with a mechanism for cleaning the ash pan from ash. The only thing the consumer needs to do is load the bunker and light the pellets. Similar designs are used when using wood chips, coal briquettes and other types of bulk fuel.

IMPORTANT! The loading tank and feeding mechanism designed for one type of fuel cannot be used for firing with other raw materials not provided by the equipment manufacturer! Such a violation will damage the boiler!

The use of different combustion and loading methods deprives solid fuel boilers of the need for frequent loading, while significantly increasing the cost. A large selection of heating equipment allows the consumer to correctly assess their own needs and make an informed choice.