Installation of a pellet boiler

Not every house building has the opportunity to connect to the main gas pipeline, and the cost of energy resources increases every year. Therefore, consumers are increasingly using solid fuel boilers for space heating. The most popular varieties among them are pellet.

The fuel for pellet boilers is special pressed pellets made from wood and agricultural waste, called pellets.

Advantages of pellet boilers:

- High efficiency from 87 to 97%;

- There is a small amount of ash, so the unit can be cleaned once a week;

- Autonomy. There is no need for a constant supply of fuel. By placing the pellets in the fuel compartment, from which they automatically enter the stove;

- Long service life - more than 25 years;

- Environmental friendliness.

The content of the article

Rules for installing pellet boilers

Before installing pellet heating, you should first calculate the heat loss and select the required performance, depending on the heated area of the room. General requirements for the installation of pellet units are given below.

Before installing pellet heating, you should first calculate the heat loss and select the required performance, depending on the heated area of the room. General requirements for the installation of pellet units are given below.

Pellet equipment should be installed in a separate room, such as a garage or basement; if this is not available, an extension should be made. The flooring in the boiler room, according to the requirements, should be made of durable and non-combustible material.For example, concrete can also be lined with metal sheets. The place where the boiler will be installed must have a concrete elevation 10–20 centimeters high.

The boiler room must be heated, have an air temperature not lower than +10C˚, with moderate humidity in order to extend the life of the equipment. Equipment must be easily accessible so that repairs and maintenance can be carried out easily. Ventilation in the room should be designed in accordance with the power specified in the equipment passport.

Installation of equipment is carried out on the basis of design documentation, in accordance with SNiP and safety requirements. Installation work must be carried out by appropriately qualified personnel.

IMPORTANT: Unscrupulous connection, piping or adjustment of the heating device can lead to an increase in fuel consumption, a decrease in efficiency, as well as failure of boiler parts.

Installation instructions for a pellet boiler

Of course, you can install the unit yourself if you have special knowledge, but it is better to seek qualified help from a specialized organization that has a construction license.

Of course, you can install the unit yourself if you have special knowledge, but it is better to seek qualified help from a specialized organization that has a construction license.

The main and important stage during installation is professionally executed design. This is followed by the following steps for installing heating equipment:

- Preparatory stage. Includes preparation of the boiler room, construction of a platform for the boiler, installation of a chimney, ventilation;

- Installation of the heating unit on a hill;

- Connecting the heating system pipes and hot water supply to the boiler;

- Connecting the smoke exhaust duct;

- Setting up and starting up the heating device.

Preparatory work

The boiler room should be prepared - the base should be leveled and strengthened, which should support a weight of up to 200 kilograms. According to the requirements, the boiler is installed vertically, so there should be no slope. The base must have a fireproof surface.

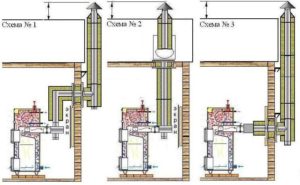

Electrical wiring is needed to automate the heating device and to illuminate the boiler room, which will provide convenience during operation. Construction of a sandwich type chimney with a height of at least 5 meters. A chimney and ventilation are also installed.

Boiler installation and piping

Installation and strapping occurs in the following sequence:

Installation and strapping occurs in the following sequence:

- The delivered boiler is mounted on the podium;

- The fuel compartment and the auger feeding pellets are mounted;

- The distribution comb is connected;

- The expansion tank and shut-off valves are being installed;

- The boiler is connected to a circuit supplying coolant and a return circuit.

Chimney connection, start-up and commissioning

After the system has been filled with coolant (water, ethylene glycol or propylene glycol), it should be connected to the chimney. Moreover, the diameter of the chimney must correspond to the diameter of the outlet pipe. And the height of the chimney is in accordance with technical requirements.

After the system has been filled with coolant (water, ethylene glycol or propylene glycol), it should be connected to the chimney. Moreover, the diameter of the chimney must correspond to the diameter of the outlet pipe. And the height of the chimney is in accordance with technical requirements.

The appropriate diameter will provide good traction regardless of wind strength and air temperature. Good traction is the key to efficient operation of pellet equipment. But this type of boiler is afraid of strong draft, but too little draft will not work. Therefore, to solve this problem, a traction stabilizer or a slide valve is used.

Most often, the chimney is made of a metal pipe, in which hatches are constructed for further cleaning.The chimney should also be equipped with a device for draining condensate and insulated. An important step is pressure testing; if it is done poorly, pyrolysis gases will leak, which will lead to a decrease in efficiency.

Afterwards, a test start-up and adjustment is carried out. A malfunctioning device will lead to the following problems: the boiler will smoke, smoke, go out and the pellets will not burn completely.

IMPORTANT: Adjustment work in pellet units should be carried out upon first start-up.