The gas boiler goes out, what should I do?

Gas boilers are the most popular and widely used in autonomous heating systems. Despite their efficiency and ease of operation, there are often cases when heating equipment goes out during the cold season, which entails a rapid decrease in room temperature. It would be natural to contact a specialist to fix the problem, but what to do if the gas boiler goes out and the technician is unable to arrive quickly? In this case, it’s worth trying to figure out what happened in order to understand why the wick goes out and eliminate the problem yourself.

Gas boilers are the most popular and widely used in autonomous heating systems. Despite their efficiency and ease of operation, there are often cases when heating equipment goes out during the cold season, which entails a rapid decrease in room temperature. It would be natural to contact a specialist to fix the problem, but what to do if the gas boiler goes out and the technician is unable to arrive quickly? In this case, it’s worth trying to figure out what happened in order to understand why the wick goes out and eliminate the problem yourself.

The content of the article

For what reason might a device suddenly go out?

The gas boiler in your house goes out, you don’t know what to do? Stopping automatic fuel supply is possible for many reasons. The most common of them is strong wind, however, this problem is familiar only to owners of private houses. In this case, the check valve, under the influence of air pressure, becomes closed, which causes an immediate stop in the gas supply.

NOTE.If the boiler blows out frequently, the chimney should be reconstructed. Perhaps its installation was carried out in deviations from the rules and regulations, or the ventilation design does not correspond to technological parameters.

The main reasons why modern boilers stop working:

- activation of the flow sensor due to stopping the coolant;

- reduction or complete cessation of air supply;

- electrical voltage surge or lack thereof;

- malfunction of the draft sensor or failure of the thermocouple;

- weak draft in the chimney;

- interruptions in gas supply.

If the boiler suddenly extinguishes, it is necessary to check one by one all the reasons that lead to the problem, starting with the presence of draft in the chimney.

Causes of attenuation of heating equipment and their elimination

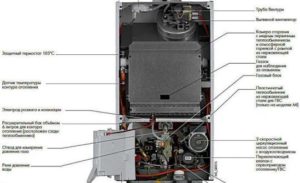

Gas boilers are a complex system with many different devices and sensors, and the breakdown of one element leads to a complete stop in the operation of the device as a whole. For example, incorrect setting of the igniter requires adjustment of the pressure (the problem is indicated by “separation” of the flame), failure of the circulation pump requires repair or replacement of the part.

IMPORTANT. Many boilers are equipped with outdated automation that does not operate in the event of reverse draft, which is extremely dangerous because it accumulates combustion products inside the premises, thereby poisoning the residents.

It may not be possible to notice the attenuation of the boiler immediately, because most often it is located in a separate room. This is fraught with the fact that the problem is detected by cold batteries and a decrease in the temperature in the home.

Insufficient gas pressure

A common situation in which the boiler extinguishes is caused by a lack of gas.The reason may lie in low pressure within the network or equipment failure. The latter includes depressurization of fasteners, which entails gas leakage and a decrease in its pressure, which causes the system to operate and shut down. In addition, the gas meter may break down, the boiler mechanism may become jammed, and the gas supply may be further interrupted.

ADVICE. To detect leaks, use an ordinary soapy sponge - bubbles will appear in places of depressurization.

Chimney malfunctions

An equally common cause is the formation of ice on the pipe as a result of cooling and settling of condensate. Gradually, its layer becomes thicker, traction decreases, and the automatic system stops supplying fuel. Solving the problem is not difficult - just thoroughly clean the chimney and effectively insulate it.

Another consequence of the problem can be backdraft - increased or changeable wind enters the pipe, blowing out the boiler. To avoid this, the pipe should be replaced taking into account its height, which should be at least 50 cm above the ridge.

Incorrect fan operation

The fan is installed to forcefully remove smoke from the combustion chamber and is controlled by a pressure sensor, which, if a malfunction occurs, makes it impossible to operate the heating equipment. It is easy to detect a breakdown:

- the discharge turbine rotates slowly or has stopped, and the motor is noisy;

- appearance on the breakdown indicator in the form “Delay in rheostat operation”.

The causes of failure include a malfunction of the inductor, wear of the bearings, imbalance of the turbine, low power or its complete absence, etc. The best solution in this case would be to contact a specialist who will repair or replace failed components.

Unstable power supply

Jumps in the network cannot be predicted, while a low voltage level leads to the attenuation of the gas boiler, and the restoration of the normal level leads to its restart. In most cases, owners will not notice anything, however, such changes have a detrimental effect on the condition of the equipment and reduce its service life.

ADVICE. To avoid turning off the boiler due to surges in the network, it is recommended to install a voltage stabilizer or an uninterruptible power supply.

Malfunctions due to severe frosts

Severe frosts lead to the rapid appearance of ice growths on the tip, which entails a cessation of oxygen access and further extinguishing of the gas boiler. It is simply impossible to knock them down, because the ice is not only outside, but also inside. The solution is to dismantle the head and defrost it in a bathtub or other container. At this time, the boiler can be started, but only under constant control and with the gas shut off in the main burner.

Self-repair of a gas boiler when it goes out

Wall-mounted boilers, equipped with an open or closed combustion chamber, are complex devices, but fixing the breakdown with your own hands is still possible, like with other types. The boiler may not work for 3 reasons:

- complete shutdown of the device;

- no ignition when turned on and the indicator and display light up;

- ignition and subsequent extinguishing of the burner.

Manipulations should be carried out in accordance with the instructions for the device, which usually indicate the main malfunctions and how to deal with them.

ADVICE. First of all, it is recommended to check the voltage, since, for example, a banal operation of the machine can cause its absence.

If the voltage is normal, you need to remove the front panel using a screwdriver, and then check all the fuses in the block. If you find a faulty one, you should replace it, which may help and the boiler will work, otherwise contact a specialist. He should also be called if a thorough inspection reveals burnt elements on the board, broken wires and leaks. Some problems can be fixed even if you lack experience and skills:

- clean the clogged mud pan;

- pump up the air if the pressure in the tank is low;

- eliminate leaks and add water to the normal level;

- adjust the circulation pump by loosening the screw in the center and bleeding the air.

Of course, an ordinary user will not be able to eliminate a complex malfunction, however, a simple malfunction can be easily resolved, which will avoid significant heat loss, save money and nerves. The components of success are strict adherence to recommendations and instructions, as well as confidence in your actions.