Do-it-yourself heat accumulator for heating boilers

Most of those homeowners who use an autonomous heating system in their homes prefer to install solid fuel boilers. Making such a purchase under the influence of intrusive advertising, few people know that these units have a number of features. In particular, in order to maintain a comfortable indoor microclimate, such a device must be heated around the clock. If the boiler goes out, the coolant cools down and the temperature in the house quickly drops. Installing a heat accumulator significantly increases the efficiency of the entire heating system and also reduces the cost of purchasing fuel. The boiler can only be serviced at a convenient time without feeling a change in the microclimate in the house.

Most of those homeowners who use an autonomous heating system in their homes prefer to install solid fuel boilers. Making such a purchase under the influence of intrusive advertising, few people know that these units have a number of features. In particular, in order to maintain a comfortable indoor microclimate, such a device must be heated around the clock. If the boiler goes out, the coolant cools down and the temperature in the house quickly drops. Installing a heat accumulator significantly increases the efficiency of the entire heating system and also reduces the cost of purchasing fuel. The boiler can only be serviced at a convenient time without feeling a change in the microclimate in the house.

The content of the article

Features of the heat accumulator and why it is needed

The main task that the heat accumulator is designed to solve is the accumulation of thermal energy and its return at a time when the boiler stops producing it. For example, when all the fuel has already burned out. In addition, such a device not only allows you to maintain optimal air temperature, but also guarantees the availability of hot water.

The main task that the heat accumulator is designed to solve is the accumulation of thermal energy and its return at a time when the boiler stops producing it. For example, when all the fuel has already burned out. In addition, such a device not only allows you to maintain optimal air temperature, but also guarantees the availability of hot water.

Thermal accumulators are used in conjunction with solid fuel boilers, as well as electric ones.With proper installation, the homeowner has every chance of reducing energy costs by 20-25%.

Principle of operation

Representing a well-insulated reservoir, the heat accumulator operates according to a simple scheme. A pipe from the boiler is connected to it from above, through which water flows. At the bottom there is a pump that supplies gradually cooling water back to the heating system. Thus, cold water is replaced by newly heated water. Any boiler works in cycles - turning off and turning on. If there is a heat accumulator, even during the passive period - i.e. until the next fuel is added, the batteries and water remain warm for some time, thanks to the flow of hot water into the system from the tank.

Possibilities

A consumer who uses a heat accumulator can operate the boiler with greater comfort. It is enough to heat it only once a day, and the temperature remains stable for twenty-four hours.

Do-it-yourself heat accumulator: diagrams and description of the process

If you decide to create a heat accumulator with your own hands, you must:

- Calculate the volume of the container.

- Determine a suitable design - the container can be cylindrical or rectangular.

- Prepare the necessary materials and components.

- Assemble and check the device for leaks.

- Connect the container to the heating system.

IMPORTANT! Before calculating the volume of the tank, it is necessary to decide how much area can be allocated for its installation.

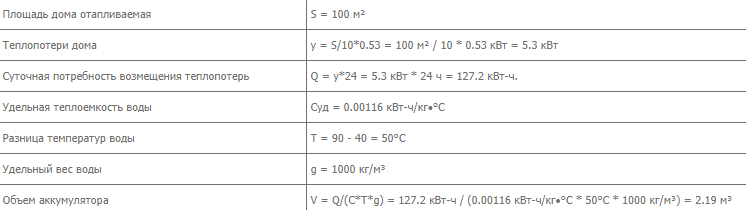

The volume of the tank will determine how long the heat will remain in the room during the period the boiler is turned off. The photo shows the calculation of the volume for a room of 100 m²:

The optimal storage device for storing heated coolant will be a cylindrical container with convex bottoms. This shape allows you to store a fairly large volume of water. Such containers can only be manufactured in a factory.

A home craftsman will make the task much easier if he finds an opportunity and uses a ready-made container. For this you can use:

- Cylinders for storing and transporting gas.

- Unused containers that are intended for use under pressure.

- Receivers that were installed in the pneumatic system of railway transport.

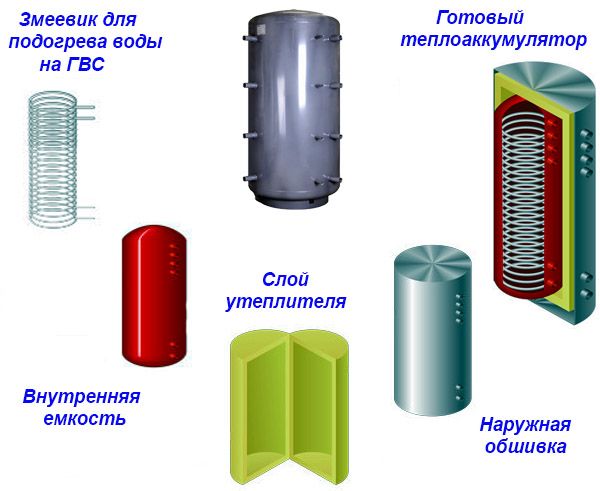

But, of course, the use of homemade tanks is also acceptable. For their production, rolled sheets with a thickness of at least 3 mm are used. Inside the container there is an 8–15-meter copper tube, 2–3 cm in diameter, pre-bent into a spiral. At the top of the tank there is a pipe for discharging hot water, and at the bottom for cold water. Each is equipped with a tap to control the flow of liquid.

The normal operation of a thermal accumulator is based on the movement of hot and cold coolant inside, while the battery is “charging”. It must be carried out strictly horizontally, and at the moment of “discharge” - vertically.

To ensure such movement, it is necessary to ensure that several simple rules are followed:

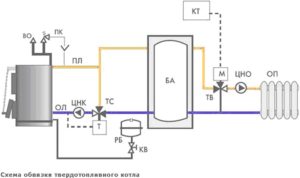

- The boiler circuit must be connected to the storage tank via a circulation pump.

- The heating system is supplied with working fluid using a separate pump unit and mixer, which includes a three-way valve - it takes the required volume of water from the storage tank.

- The pump unit, which is installed in the boiler circuit, cannot be inferior in efficiency to the unit that supplies the working fluid to the heating devices.

Insulation of the heat accumulator

How are containers insulated? To solve this problem, basalt wool, the thickness of which is 60–80 mm, is considered the best option. Polystyrene foam or extruded polystyrene foam is not recommended. Another reason why cotton wool is used is its fire safety. Thermal insulation is installed between the container and the metal casing, which is made from sheet metal - it must be painted.