Gas boiler service life

There are things without which it is difficult to imagine our daily existence. One of the most necessary heating appliances in a private home is a gas boiler.

There are things without which it is difficult to imagine our daily existence. One of the most necessary heating appliances in a private home is a gas boiler.

The content of the article

Types of boilers

In the modern world there are many types of gas boilers. They can be classified according to functionality and type of installation.

By functionality

Gas boilers are divided into 2 groups.

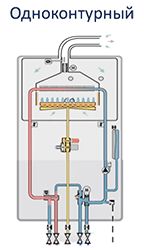

- Single-circuit: used only for space heating.

- Double-circuit: in addition to the heating function, it is also a source of hot water.

REFERENCE. Single-circuit boilers can also serve as a source of hot water. To do this, you need to purchase a special device - a boiler.

However, such a tandem is almost always more expensive than a simple double-circuit boiler.

According to installation principle

Wall mounted

This placement principle requires special technical characteristics from the equipment. As a rule, wall-mounted boilers are assembled from lighter metals and lightweight materials. This does not have a positive effect on the reliability of the equipment.

When purchasing wall-mounted boilers, be prepared for frequent repairs and constant maintenance!

Floor mounted

These gas boilers are much more practical and reliable. They are more powerful than their wall-mounted counterparts and are capable of heating large areas, but they also weigh more. The operation of such a boiler often requires a separate room due to the large number of different equipment.

Boiler service life determined by the manufacturer

Each manufacturer assembles its products from a variety of materials. Accordingly, the service life of a specific gas boiler model may vary greatly.

Important! As a rule, equipment manufacturers set a service life of 10-12 years.

The duration of operation depends on the model, operating conditions and type of boiler.

However, application practice shows that with proper care, the life of the boiler can be significantly extended.

In addition to timely maintenance, many factors influence the longevity of the boiler.

These include:

- hardness of water;

- equipment class;

- pressure;

- factors and operating conditions;

- the type of room in which the boiler is installed and much more.

The influence of the class and price of the device should not be underestimated. In the so-called “low” class, low-quality Chinese materials are used.

The lack of an electronic display reduces overall operating efficiency. In the middle and premium segments, much higher quality European-made parts are used. Expensive models have a self-diagnosis function and finer functional settings, which has an extremely positive effect on the functioning of the device.

Parts that affect service life

Devices of different types and price categories use materials of different quality and characteristics.Some details have the greatest impact on the long and productive operation of a gas boiler.

Thermal conductor material

The wear rate of a gas boiler, as well as the efficiency of its operation, depends on the material of the heat conductor.

- Floor-standing boilers use parts made of steel and cast iron - they are more reliable and resistant to wear.

- In wall-mounted equipment, copper radiators are used to reduce weight. This material is highly dependent on water quality and is susceptible to corrosion.

Radiator type

It is worth noting that in addition to the material of manufacture, the durability of the radiator is also influenced by the type of its design.

In the production of boilers, 2 types of radiators are used.

- Serpentine: this type of radiator is excellent for descaling. It is easy to maintain and durable. To restore its functionality, simply remove it and clean it. After this, you can continue to operate the boiler.

- Bithermal: cannot be cleaned. The cost of replacing it in case of failure is a large part of the amount spent on the boiler itself.

Pump

Another part that is constantly in contact with water. Its durability depends primarily on the hardness of the water used in the boiler.

Advice. A regular, or even better, polyphosphate filter, which purifies the water from harmful salts, can save the pump.

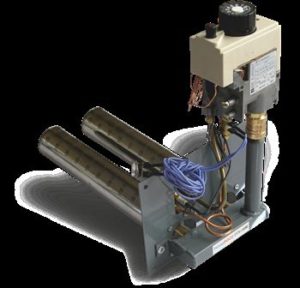

Burner type

The operation of the entire gas system also depends on the type of burner installed. They work on the atmospheric or forced principle.

Atmospheric principle

It takes air directly from the room where the gas boiler is installed. The product obtained as a result of combustion is removed through the hood.In this type of device, a lot of soot and other harmful deposits accumulate, which complicates the operation of the system and increases the load on its parts.

Coercive principle

The air comes from the street. Combustion products in such a burner device are forced out through a special chimney, which is more efficient from an operational point of view.

Reference. The presence of electronic elements also adversely affects the service life of a gas boiler.

Features of use that affect service life

In addition to the installed parts, operating conditions also have a special impact on the durability of the device.

- The boiler should be selected according to the parameters of the room in which it will operate. It is especially important to choose a device with a peak power reserve of 15–20% of that planned for operation.

- The data of the premises itself also plays an important role. Gas boilers are afraid of corrosion and rust. As a result, it is necessary to exclude the presence of moisture and avoid excess air pressure.

- The key to a long service life of the device is good, high-quality water. Hard water contains a large amount of salts and is the main cause of scale formation on parts in contact with water. This greatly affects the performance of the device as a whole. Dealing with hard water is very simple - you need to install any filter that purifies the water. It is best to use polyphosphate filters designed specifically for heating systems.

- The decisive factor in the struggle for the performance of the gas system is the correct calculation of the device power required for constant operation. If you take it “back to back”, then the work resource will quickly be exhausted.The parts of the device will become unusable after some time. Therefore, it is necessary to have a power reserve of at least 20% of the calculated one. This will prolong the stability and performance of the device.

Thus, by carrying out timely maintenance and taking all the above measures, you can achieve stable and productive operation of the gas boiler for a period of more than 15 years.