Connection diagram for a solid fuel boiler with an electric boiler

In the absence of gas, the cheapest way to heat a private residential or garden house is to install a solid fuel boiler. However, this option is associated with a number of negative aspects. The main one is the need to constantly add fuel to the firebox. If this is not done in time, the fire will go out, which will lead to a rapid cooling of the house or even freezing of the entire pipeline system. There is also the opposite problem - the possibility of overheating of the coolant, since it is very difficult to regulate the combustion intensity in some boiler models. Risks can be reduced by installing a combined system of two types of boilers: solid fuel and electric.

In the absence of gas, the cheapest way to heat a private residential or garden house is to install a solid fuel boiler. However, this option is associated with a number of negative aspects. The main one is the need to constantly add fuel to the firebox. If this is not done in time, the fire will go out, which will lead to a rapid cooling of the house or even freezing of the entire pipeline system. There is also the opposite problem - the possibility of overheating of the coolant, since it is very difficult to regulate the combustion intensity in some boiler models. Risks can be reduced by installing a combined system of two types of boilers: solid fuel and electric.

The content of the article

How to connect a solid fuel boiler to an electric one

Currently, mass production of combination boilers has been established, which can operate on both wood and electricity. Such units are very efficient and economical, despite the fact that their efficiency is approximately 5% lower compared to analogues that use only one type of fuel. Such equipment is not cheap, but many also cannot afford to heat it exclusively using electricity. Sometimes it is more profitable to independently assemble a system of two boilers of different types.

The leading role in this combination is played by the wood-burning apparatus (as an alternative to wood, for example, coal or peat can be used). When a fire burns in the firebox, it provides hot water supply and heating of the premises. Electrical equipment is turned on only if the coolant temperature drops below a certain level (usually set to 50°C). Despite its auxiliary role, such insurance is very important for several reasons:

- even if the wood burns out completely, the temperature in the house will not drop significantly;

- the cooled coolant, flowing through the return pipeline, promotes corrosion and forms condensation on the walls of the chamber, which mixes with soot. As a result, a plaque that is difficult to remove appears;

- the emission of combustion products into the atmosphere is reduced.

Liquid circulation in the system is ensured by two hydraulic pumps (one for each boiler).

Important! A more powerful pump should be installed on a solid fuel boiler than on an electric one (for example, 0.6 atm versus 0.5 atm). Otherwise, the circulation may unplannedly go in a small circle. As a result, the coolant may boil, followed by pipe rupture in the stagnation area.

To prevent the devices from interfering with each other’s operation, check valves are installed at the supply outlets.

Important connection details

For the system to function effectively, it is necessary to make preliminary calculations. First of all, you should find out whether it is possible in principle to install such equipment in a given building. Low or unstable voltage in private homes is not uncommon. Under such circumstances, installing an electric boiler may be completely useless.

Important! When choosing an electric boiler, it is necessary to take into account the state of the electrical wiring in a particular house, as well as the total power of all electrical appliances in it, otherwise, when the heater is turned on, a short circuit may occur or the circuit breaker will constantly turn off.

The correct choice of hydraulic pumps is of great importance. When purchasing, you need to pay attention to their parameters. Low-power devices will not be able to provide the necessary circulation of liquid. Accurate calculations should be made taking into account the diameter and length of the pipelines.

For more economical operation of the system, a heat accumulator is often built into it. This is, as a rule, a container in which water for domestic hot water is accumulated. It prevents the cooled liquid from directly entering the solid fuel boiler.

Connection diagram of a solid fuel boiler to an electric one

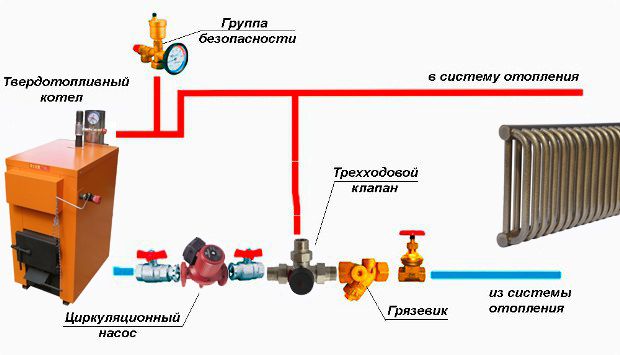

Boiler piping is carried out in parallel. Each of them is equipped with a hydraulic pump and a check valve, which does not allow water to circulate between the two devices and prevents leakage from the water jacket in the event of an accident.

A thermostat is installed in the small circle of the wood boiler. When the temperature drops, it directs the liquid to the electric boiler. In addition, the system contains sensors. They can be of two types: to measure the temperature of the coolant in the pipe or the air temperature in the room. When the specified parameters are reached, the sensors transmit a signal to the automation, which turns on the heating elements. They temporarily become the main source of heat.

The principle of operation of the circuit is quite simple. The liquid heated by the solid fuel boiler flows through pipes into the radiators.From there, using a pump, it returns back through a sensor, thermostat and check valve to reheat. If the flame goes out and the temperature drops below critical, the pump of the wood-burning unit will turn off based on a signal from the sensor, and the thermostat will block the access of the coolant to the tank, directing it in a small circle through the electric boiler. At the same time, the heating elements will automatically start working.

The main disadvantage of heating with solid fuel is the need for constant monitoring of the process. Modern long-burning stoves allow you to load fuel 1-2 times a day, however, this is not always possible (for example, in the case of a long absence of owners). In this situation, the combined circuit will maintain the set temperature in the house until the residents return.

True, just install a 3-way valve for mixing.

Why scratch your right ear with your left foot. Place two boilers in series with one pump, without complicated valves. As soon as the temperature is at b.t. the boiler will drop, the heating elements will turn on, the temperature will rise, the heating elements will turn off.