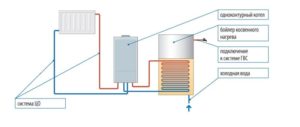

Connection diagram for a double-circuit boiler

Indeed, it is possible to connect and install a double-circuit boiler yourself. It is important to adhere to certain requirements and remember that the approach to each device is considered individual. All possible features of the connection diagram for a double-circuit boiler will be discussed below in the article.

The content of the article

How to connect a double-circuit boiler correctly

How to piping a double-circuit wall-mounted heating boiler with your own hands? First, you need to understand what the operating principle of the presented design is. Operation is carried out due to two circuits that do not affect each other in any way.

How to piping a double-circuit wall-mounted heating boiler with your own hands? First, you need to understand what the operating principle of the presented design is. Operation is carried out due to two circuits that do not affect each other in any way.

They are both responsible for the correct operation of the coolant. Only one of them guarantees operation without interruptions in the heating system, while the other provides the same, but in the hot water supply system.

Connecting a double-circuit boiler is quite simple. The first step is to hang the unit on the wall. Next, you will need special brackets, which are usually included with the heating equipment.

This is done using self-tapping screws and plastic dowels. And also, to install them, you need to arm yourself with a building level and a plumb line. Thanks to them, it will be possible to make the connection exactly along a horizontal line.

As you can see, there is nothing complicated about this, so the final step - hanging the boiler itself on the fasteners is not difficult. And all that remains to be done in the future is to connect it with the necessary parts, purchase a chimney and connect it to the network.

What should be the piping of a double-circuit wall-mounted boiler?

To avoid maximum pressure levels, it is necessary to first secure the device from blockages and make the correct piping. The best option will depend on the type and model of the boiler.

To avoid maximum pressure levels, it is necessary to first secure the device from blockages and make the correct piping. The best option will depend on the type and model of the boiler.

Features of piping a double-circuit boiler with an indirect heating boiler

The ideal situation is when the piping scheme of a double-circuit heating boiler is such that the boiler is installed together with the boiler, and not in an already existing system. During installation, it is advisable to adhere to the following rules:

The ideal situation is when the piping scheme of a double-circuit heating boiler is such that the boiler is installed together with the boiler, and not in an already existing system. During installation, it is advisable to adhere to the following rules:

- The surface selected for installation should be as flat as possible;

- The location of the additional element should be chosen close to the central structure, and also ensure accessibility;

- Install filters to equip yourself with the best quality water;

- For long-term operation, it is necessary to equip all circuits with a ball valve.

And in order for functioning to occur at the highest level, it is recommended to include in the harness:

- Pumps to improve circulation;

- A filter system or a sump for purifying cold water;

- Check valve to prevent movement in the opposite direction;

- Three-way mixing valve to prevent excess liquid from entering;

- Two-way thermostat;

- For high hot water consumption, you can purchase an additional flow-through heat exchanger.

Tying a double-circuit heating boiler with polypropylene

When piping a double-circuit heating boiler with polypropylene, it is best to use a manifold and hydraulic arrows. In this case, you do not have to resort to the use of metal pipes of considerable length, since the liquid rarely reaches temperatures from 70 to 80 degrees Celsius. For each circuit, a circuit with circulation equipment should be made.

When piping a double-circuit heating boiler with polypropylene, it is best to use a manifold and hydraulic arrows. In this case, you do not have to resort to the use of metal pipes of considerable length, since the liquid rarely reaches temperatures from 70 to 80 degrees Celsius. For each circuit, a circuit with circulation equipment should be made.

This is necessary to guarantee safety and reliability. In this case, the main load will fall on the auxiliary pumps when pumping coolant. In the place where cold water is supplied, it is advisable to install filters to supply both fine and coarse purification.

IMPORTANT! To prevent polypropylene from bursting, you should first attach it to the outlet.