Do-it-yourself draft regulator for solid fuel boilers

Working independently in any field means constantly saving money, enjoying the process and often achieving satisfactory results. Installing and adjusting the traction is not considered a labor-intensive task. However, it is worth considering some nuances and knowing the exact algorithm of actions. Do-it-yourself draft regulator for solid fuel boilers - this article will discuss this.

The content of the article

Basic information - design

Of course, you first need to understand what we are dealing with and why the regulator itself is needed. First of all, it is considered important to ensure the influx of cold air masses. They must be saturated with oxygen. To provide presence, a special valve is installed on the lower part. As for the principle of operability, it is the need for a drive. Moreover, it is he who will guarantee the formation of an angle for opening the damper. Speaking about the combustion chamber, it is worth mentioning the temperature sensor. The last of them transmits a signal to the device to open or close the mechanism. However, if quite strong heating occurs, the damper closes slightly, which leads to a decrease in the intensity of the combustion process. When normalized, the part is reopened and activity resumes to its full potential. Thus, fuel economy should be mentioned since it only burns when it is actually needed for the design.

Of course, you first need to understand what we are dealing with and why the regulator itself is needed. First of all, it is considered important to ensure the influx of cold air masses. They must be saturated with oxygen. To provide presence, a special valve is installed on the lower part. As for the principle of operability, it is the need for a drive. Moreover, it is he who will guarantee the formation of an angle for opening the damper. Speaking about the combustion chamber, it is worth mentioning the temperature sensor. The last of them transmits a signal to the device to open or close the mechanism. However, if quite strong heating occurs, the damper closes slightly, which leads to a decrease in the intensity of the combustion process. When normalized, the part is reopened and activity resumes to its full potential. Thus, fuel economy should be mentioned since it only burns when it is actually needed for the design.

ATTENTION! An individual regulator is selected for each boiler.

Regulators can be:

- Mechanical.

- Electronic.

Installing the draft regulator yourself

So, what will you need to get the job done:

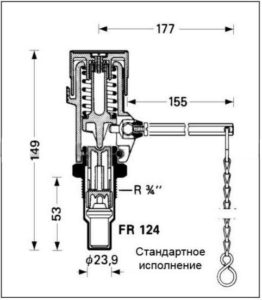

- Steel spring.

- A sheet whose thickness should be about 3–5 millimeters.

- Chain.

- Aluminum pipes in the amount of two pieces.

- Tap.

When all the necessary items have been collected, you can begin the main course of work:

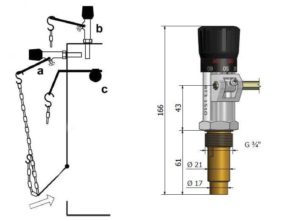

- Two pipes must be placed as close as possible to the wall of the unit.

REFERENCE! Moreover, one of them should be placed with a tap and the first lever, and the second - between a regular lever and a product with a spring.

- The next step is to connect the chain to the part that contains the damper.

- All possible fasteners must be cut out using a grinder. This is made from steel sheet.

- As for the lever axis, this is the location between the fasteners and other parts.

Thanks to this algorithm of actions, the following move is ensured:

- Initially, the tap ensures the displacement of each tube.

- Thanks to this, the upper part heats up, after which the lever rotates to the required angle.

- This pushes the second lever.

- Further, a component of the system lowers the chain, which helps tilt the damper.

Setting up the draft regulator

In general, using the instructions that come with the device, you can easily understand the design settings. However, in case of its loss, a step-by-step list of moves is provided:

- First you need to light the boiler. Then open the door, but most importantly, do not attach the chain to it.This is necessary in order to create access for air masses.

- Then loosen the screw that secures the position on the adjusting mechanism.

- After which you can set a certain temperature by turning the handle.

- When the value is reached, it is advisable to attach the actuator to the damper. It should be a little open.

- Finally, secure the screw.

The main thing is to periodically monitor the thermometer and not rush to change the settings. In addition, the distance of the chain is important - less than 1 millimeter. Some models of the device are characterized by a certain delay, since the coolant is unable to extinguish at lightning speed.