Flushing the gas boiler heat exchanger

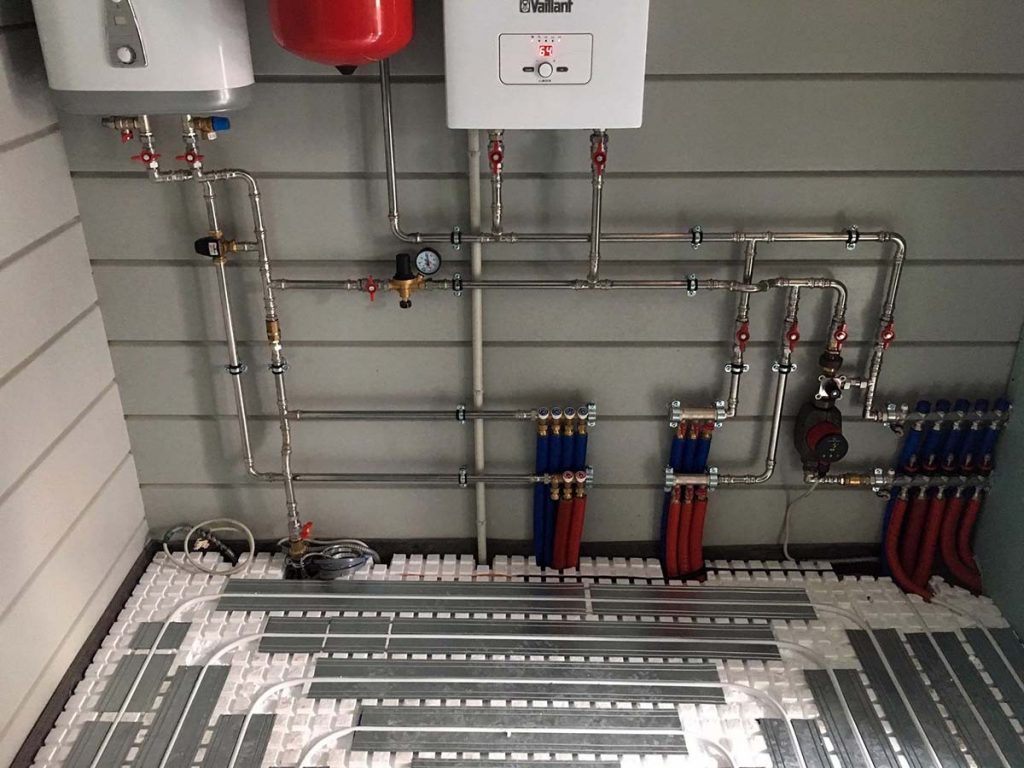

The task of any gas boiler is to heat the coolant as efficiently as possible and supply it to the heating system and to heat water for hot water supply. During operation of the boiler, gas combustion products are deposited on the outer walls of the heat exchanger, and the coolant - most often ordinary tap water - clogs the inner surface of the tubes with its deposits. This leads to significant losses in boiler power and, accordingly, an increase in gas consumption, and in the future, if preventive maintenance is not performed, it can lead to boiler failure. For efficient operation of boiler equipment, periodic cleaning of the boiler and all its working elements is necessary.

The task of any gas boiler is to heat the coolant as efficiently as possible and supply it to the heating system and to heat water for hot water supply. During operation of the boiler, gas combustion products are deposited on the outer walls of the heat exchanger, and the coolant - most often ordinary tap water - clogs the inner surface of the tubes with its deposits. This leads to significant losses in boiler power and, accordingly, an increase in gas consumption, and in the future, if preventive maintenance is not performed, it can lead to boiler failure. For efficient operation of boiler equipment, periodic cleaning of the boiler and all its working elements is necessary.

The content of the article

How often should the boiler be cleaned?

Every year after the end or before the start of the heating season, a preventive inspection of the boiler is recommended for leaks, removal of dust, dirt, and cobwebs. Once every two to three years it is necessary to clean the gas nozzles, heat exchanger and chimney.

Every year after the end or before the start of the heating season, a preventive inspection of the boiler is recommended for leaks, removal of dust, dirt, and cobwebs. Once every two to three years it is necessary to clean the gas nozzles, heat exchanger and chimney.

How to clean a boiler yourself: step-by-step guide

To carry out this work you will need the following tool:

- screwdrivers “+” “-”;

- set of open-end wrenches;

- gas key;

- vacuum cleaner;

- metal brush and soft bristle brush;

- rags.

Now let's get straight to the step-by-step cleaning guide.

A preventative inspection of the boiler begins with checking for gas leaks. To do this, a soap solution is prepared and all gas pipe connections from the tap to the burner in the boiler are soaked in the soap solution. If a leak is detected, you must call a specialized company to fix the problem. Under no circumstances should you try to fix a gas leak yourself. If the gas pipeline is in order, you can continue servicing the boiler.

A preventative inspection of the boiler begins with checking for gas leaks. To do this, a soap solution is prepared and all gas pipe connections from the tap to the burner in the boiler are soaked in the soap solution. If a leak is detected, you must call a specialized company to fix the problem. Under no circumstances should you try to fix a gas leak yourself. If the gas pipeline is in order, you can continue servicing the boiler.- All threaded connections are checked for leaks; if rusty streaks or hanging drops of water are detected, it is necessary to disassemble the assembly and replace the gasket.

- Before starting to disassemble the boiler, it is imperative to turn off the gas supply valve, close the valves on the inlet and outlet pipes of the hot water supply and heating, and turn off the power to the boiler.

- At the initial stage, the boiler body is disassembled. This opens access to the combustion chamber. To quickly and correctly dismantle the boiler elements, in order to avoid making mistakes, you must be guided by the boiler passport and carefully study the equipment diagram.

- After removing the outer casing, use a vacuum cleaner and brush to remove all dust and dirt from the internal space, and clean all internal elements from dust and dirt.

- Check the pressure in the expansion tank. For this you need a regular car pressure gauge. If the pressure is below 1.5 atmospheres, then using a car pump it must be raised to the required value.

- At the bottom of the combustion chamber, the injectors are cleaned with a brush and rags, and all debris and dust are removed.

Cleaning the heat exchanger of a gas boiler is the main task

The main element of the boiler is the heat exchanger. The heat in the house depends on its operation, the hot water in the tap in the kitchen or bathroom, and gas costs are directly dependent on the quality of the heat exchanger. Therefore, special attention must be paid to cleaning it.

The main element of the boiler is the heat exchanger. The heat in the house depends on its operation, the hot water in the tap in the kitchen or bathroom, and gas costs are directly dependent on the quality of the heat exchanger. Therefore, special attention must be paid to cleaning it.

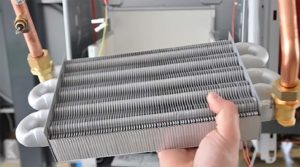

Types of heat exchangers and how to clean them

The main materials from which heat exchangers are made:

- steel;

- cast iron;

- copper.

Each material has certain advantages and disadvantages. The most versatile is the heat exchanger made of steel. This is the most accessible material. Main advantages:

- cheapness;

- light weight;

- high plasticity.

It is plasticity that prevents thermal stresses from arising in places where the material is actively heated, which prevents the formation of cracks. However, the main disadvantage is low corrosion resistance, which reduces the service life of steel heat exchangers, entails the second one - to extend the service life, manufacturers are forced to increase the wall thickness and diameter of the tubes, which leads to an increase in the amount of coolant, the size of the device and, as a consequence, an increase in fuel consumption for heating it.

It is plasticity that prevents thermal stresses from arising in places where the material is actively heated, which prevents the formation of cracks. However, the main disadvantage is low corrosion resistance, which reduces the service life of steel heat exchangers, entails the second one - to extend the service life, manufacturers are forced to increase the wall thickness and diameter of the tubes, which leads to an increase in the amount of coolant, the size of the device and, as a consequence, an increase in fuel consumption for heating it.

Cast iron heat exchanger It is practically not subject to corrosion, but has very low ductility and high weight. Low ductility leads to stresses appearing at the interface between strong heating of the metal of the device and its warm part, leading to the occurrence of cracks. This problem is solved by installing a three-way valve, which mixes hot coolant with cooled coolant, which allows liquid to enter the heat exchanger at the required temperature.

Cast iron heat exchanger It is practically not subject to corrosion, but has very low ductility and high weight. Low ductility leads to stresses appearing at the interface between strong heating of the metal of the device and its warm part, leading to the occurrence of cracks. This problem is solved by installing a three-way valve, which mixes hot coolant with cooled coolant, which allows liquid to enter the heat exchanger at the required temperature.

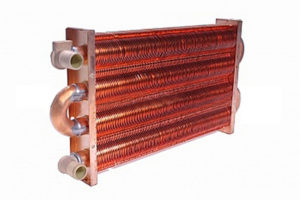

Copper heat exchanger has a number of advantages over cast iron and steel. First of all, low weight, correspondingly compact dimensions and small internal volume of the device. Compared to steel, it has high corrosion resistance. The copper heat exchanger requires less fuel to heat. The disadvantages include the high cost of the material.

Copper heat exchanger has a number of advantages over cast iron and steel. First of all, low weight, correspondingly compact dimensions and small internal volume of the device. Compared to steel, it has high corrosion resistance. The copper heat exchanger requires less fuel to heat. The disadvantages include the high cost of the material.

In double-circuit boilers, in addition to heating the coolant, the function of heating water for domestic needs is performed. There are two types of heat exchangers:

- Dual (bithermic).

- Separate, consisting of two heat exchangers, each of which performs its own function. The primary heats the coolant, and the secondary heats water for hot water supply.

Bithermic heat exchanger It is a “pipe-in-pipe” system in which the heating fluid flows along the outer circuit, and hot water is prepared in the inner circuit. It is located directly in the combustion chamber of the boiler.

Bithermic heat exchanger It is a “pipe-in-pipe” system in which the heating fluid flows along the outer circuit, and hot water is prepared in the inner circuit. It is located directly in the combustion chamber of the boiler.

In a separate heat exchanger The coolant from the primary heat exchanger heats the water in the secondary. The primary is located in the combustion chamber, and the secondary is located outside it. To operate a separate heat exchanger, a three-way valve is used, which directs the coolant flow depending on the task - either to the heating system or to prepare hot water.

In a separate heat exchanger The coolant from the primary heat exchanger heats the water in the secondary. The primary is located in the combustion chamber, and the secondary is located outside it. To operate a separate heat exchanger, a three-way valve is used, which directs the coolant flow depending on the task - either to the heating system or to prepare hot water.

A single-circuit boiler uses only one heat exchanger, which is responsible only for heating the coolant. In order to prepare hot water using a single-circuit boiler, it is necessary to install an indirect heating boiler, which is connected to the heating system.

Flushing the heat exchanger: step-by-step guide

- The heat exchanger is disconnected from the pipes, sensors and carefully removed from the gas boiler.

- After removing this element, they begin to inspect it. If deposits of soot and metal salts are detected on the outer parts, proceed to extremely careful removal of the deposits using a scraper and a metal brush, trying not to damage the heat-removing cells.

- If deposits cannot be removed mechanically, the external surface is cleaned with chemicals. The heat exchanger is immersed in a tank with an aqueous solution of special products; you can also use household chemicals to clean gas stoves, grills and ovens. After several hours of soaking in the solution, the heat exchanger is removed, cleaned of any remaining softened deposits and washed under running water.

- To clean a heat exchanger at home from internal scale on the tubes, the most suitable and affordable remedy is citric acid, as the most gentle chemical agent.

- To perform this work, service companies use special equipment - a booster, which is a pump with a container for a special flushing liquid and connecting hoses. But it is quite possible to make a booster at home. To do this, it is enough to have a circulation pump and a plastic tank of a suitable size. Operating principle: the element to be washed is placed in the tank, a hose connected to the circulation pump is inserted into one of the holes in the heat exchanger, the second hose coming out of the pump is tightly connected to the tank at the lowest point.The entire system is filled with a solution of water and citric acid preheated to 70 degrees in the proportion of 20–30 grams of acid per liter of water, and is started for 2–3 hours of continuous operation. After the process is completed, the heat exchanger is removed, washed with running water to remove any remaining active solution, dried and installed in place.

- In the absence of a booster, the heat exchanger is placed in a container with a hot solution of water and citric acid in the same proportion. In case of severe contamination, the proportion of citric acid can be increased or a descaling agent can be used; a hydrochloric acid solution can be used with caution, as well as a toilet cleaner such as Silite that removes plaque, but still citric acid is the most gentle means. The heat exchanger is periodically removed from the container, washed under running water and, if the cleaning process does not achieve the goal, it is placed back into the preheated solution.

- When the required cleaning result is achieved, the device, after thorough rinsing under running water, is dried and installed.

Important points for caring for boiler equipment

For long uninterrupted operation of the boiler it is necessary:

Regularly at least once a year, or better yet twice, after the end of the heating season and before it begins, clean the boiler from dust and dirt. These simple manipulations significantly extend the service life of boiler equipment.

Regularly at least once a year, or better yet twice, after the end of the heating season and before it begins, clean the boiler from dust and dirt. These simple manipulations significantly extend the service life of boiler equipment.- Once every two to three years, be sure to clean the heat exchanger and chimney, this will allow the boiler to operate at maximum efficiency.

- Once every three years, it is recommended to flush the entire heating system, thereby increasing the heat output of the radiators.

- If cleaning the boiler and heat exchanger is being carried out for the first time, it is recommended to take photos and video recordings of your actions, which will allow you to avoid mistakes during installation and assembly of the removed and cleaned boiler elements.

- An important detail is savings. Carrying out these procedures yourself allows you to save money and be sure that the work is done efficiently.