Operating principle of a pyrolysis boiler

Currently, several methods are used to heat private houses. Given their popularity, gas equipment comes first. But the ever-increasing cost of gas makes such systems less efficient. Electrical equipment is subject to the same shortcomings as gas equipment. Their main advantage is uninterrupted operation without human intervention.

Currently, several methods are used to heat private houses. Given their popularity, gas equipment comes first. But the ever-increasing cost of gas makes such systems less efficient. Electrical equipment is subject to the same shortcomings as gas equipment. Their main advantage is uninterrupted operation without human intervention.

Solid fuel equipment is cheaper. But you need to download them quite often. Therefore, long-burning boilers designed for daily operation are a good alternative to gas and electric.

The content of the article

What is a pyrolysis boiler?

These devices try to use automation when organizing the combustion process.

Important to remember! It is impossible to stop the combustion process. And further ignition of the boiler is possible only in manual mode.

The designers' task is to create a smoldering process that would not stop for a long time and at any moment could develop into a combustion process.

Operating principle of a long-burning pyrolysis boiler

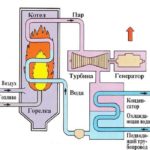

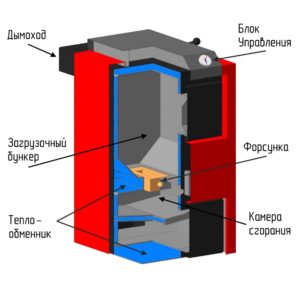

The boiler, based on the pyrolysis effect, is a boiler with a large loading chamber and two combustion chambers.In the first combustion chamber, if necessary, the smoldering mode is maintained, as well as the firewood ignition mode. The combustion process of wood is always incomplete. The exhaust gases released during this process enter the second chamber, where oxygen is mixed with them, and then the process of final combustion of this mixture occurs. The combustion temperature reaches 1100 degrees Celsius.

Features of the boiler

Long-burning pyrolysis boilers come with both top and bottom loading of fuel. Experts debate a lot about which option is better. Each of them has its own advantages and disadvantages. Top loading options have The advantage is that the process of smoldering and burning dries out the wood, which is preparing for combustion. The disadvantages of both options include the fact that the boiler cannot be loaded with firewood. Therefore, such options have a very large chamber for loading firewood and it must be loaded completely if the owner wants to achieve maximum operating time on one load.

Long-burning pyrolysis boilers come with both top and bottom loading of fuel. Experts debate a lot about which option is better. Each of them has its own advantages and disadvantages. Top loading options have The advantage is that the process of smoldering and burning dries out the wood, which is preparing for combustion. The disadvantages of both options include the fact that the boiler cannot be loaded with firewood. Therefore, such options have a very large chamber for loading firewood and it must be loaded completely if the owner wants to achieve maximum operating time on one load.

What you need to remember when using a pyrolysis boiler

What does the owner of such a system need to remember? The operating time of modern pyrolysis boilers can exceed 24 hours.

Important! To load the system, you need to choose a time so that in a day you can make the next load and service the boiler.

System maintenance includes removing ash and cleaning the boiler, as well as removing condensate. Also, one of the features of boilers of this type is the need to load firewood with a humidity percentage of at least 5. That is, it must be almost perfectly dry firewood. If this is not done, then such a boiler turns from a pyrolysis boiler into an ordinary one with an operating time of up to eight hours.When treated in this way, the efficiency of such a heating system is significantly reduced.

System maintenance includes removing ash and cleaning the boiler, as well as removing condensate. Also, one of the features of boilers of this type is the need to load firewood with a humidity percentage of at least 5. That is, it must be almost perfectly dry firewood. If this is not done, then such a boiler turns from a pyrolysis boiler into an ordinary one with an operating time of up to eight hours.When treated in this way, the efficiency of such a heating system is significantly reduced.

Are pyrolysis boilers safe?

The main disadvantage of such systems is the impossibility of automatic operation when the supply of electricity to the heating system is interrupted, since the fans and pumps of the system are powered. Therefore, it is important to provide for the ability to cool the system in the event of a power outage.