The principle of operation of a gas boiler

In the heating system, the key element is the gas boiler, which is designed to heat the coolant. Operation is cheaper than using an electric boiler or heating with wood. Compactly placed and easy to use. That is why gas heating is considered the best option for technological and comfortable heating of a room. To operate the equipment correctly, you need to understand how it works.

In the heating system, the key element is the gas boiler, which is designed to heat the coolant. Operation is cheaper than using an electric boiler or heating with wood. Compactly placed and easy to use. That is why gas heating is considered the best option for technological and comfortable heating of a room. To operate the equipment correctly, you need to understand how it works.

The content of the article

The principle of operation of a gas boiler

The main task of the boiler is to heat the coolant using direct transfer of thermal energy. Accordingly, heat passes through the combustion of gas. There are many varieties with different working processes. To know how a particular device works, you need to consider each:

- Single-circuit. The device is not capable of providing the required consumer share of water heating. Gas is supplied under pressure from the general network and then sent to the chamber where combustion occurs. The heat supply power is regulated using an automation system and sensors. During the combustion of the flame, a sufficient amount of heat is generated, which spreads through the entire heating structure of the heat exchanger. A fluid rotates inside to ensure operation. Due to the influence of a jet of burning gas, heating occurs from the outside. To make a single-circuit boiler, cast iron or copper is used.

- Dual-circuit. In addition to heating the room, it heats water.The operating principle is similar to the single-circuit one, but there are additional functions and elements. Hot water supply does not pass directly; to obtain hot water you need to maintain the temperature of the main circuit. In summer, you can heat the water separately; to do this, you need to install a tap that interrupts the circulation of the coolant.

- Wall. Most often used for heating small rooms. The principle of service is similar to single-circuit and double-circuit boilers. The wall-mounted device has smaller parts, due to which it has a compact size. Additional parts are used - a membrane tank, a circulation pump. It can be single-circuit or double-circuit, with a closed or open combustion chamber. The operating principle is concentrated on a complex automation device and requires proper maintenance. The automation system of the wall-mounted device is capricious in operation and often produces malfunctions. It is not recommended to repair it yourself; it is best to contact a specialist.

- Condensation. Applies additional force of water vapor. Equipped with a fan that regulates the number of revolutions. Due to these changes, the combustion chamber remains closed and regulates the gas to air ratio. A coaxial chimney releases used gases. For economical service of the device, you need to keep the temperature of the coolant in the opposite pipeline less than 57 degrees. A condensing device works better at a reduced constant temperature of the heating structure, so it is better to use heated floors together. A distinctive feature of this device is its large area. Condensation occurs in the heat exchanger, so it is made of stainless steel.

IMPORTANT! The operating principle of the equipment is almost the same, with the exception of a few details. The service process occurs as follows: water flows through the main line through the circulation pump directly to the heat exchanger. After which the gas valve opens, gas flows through the nozzles to the burner. The ignition electrode is activated and the gas is ignited. When the proper temperature is set, the fire goes out. Some models have an external thermostat, thanks to which automatic heating is turned on when the degrees drop. A three-way valve is used to switch from heating to domestic hot water. Combustion products are removed through the chimney.

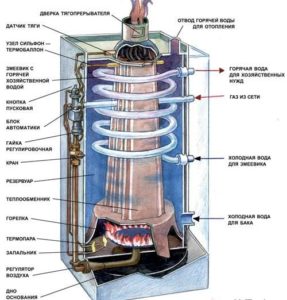

Gas boiler device

Difficulties may arise during operation. It is advisable to know what the equipment consists of. This knowledge will also allow you to choose the appropriate heating model. The main elements of the devices are:

Difficulties may arise during operation. It is advisable to know what the equipment consists of. This knowledge will also allow you to choose the appropriate heating model. The main elements of the devices are:

Burner. The design has a rectangular shape and is equipped with nozzles. Injectors are mechanical gas atomizers controlled either mechanically or by a valve. It is used to atomize fuel, which reaches the burner and is distributed. Due to this, the surface of the radiator is heated equally on all sides and along the surface. There are two types:

- Atmospheric. Air is drawn in to maintain the flame from the room. This burner does not require electricity, which is an advantage. When installing, it is necessary to have a window and natural ventilation. An atmospheric burner is installed near the chimney. This type is used in tabletop devices.

- Turbocharged. It works using a built-in fan that removes combustion products through a coaxial chimney. No chimney draft or ventilation is required.When operating a turbocharged burner, electricity is required, which is a disadvantage. Used in wall-mounted devices, the output is made through the wall.

Heat exchanger. The design has the shape of a box, with tubes distributed inside through which water flows. The heat exchanger assembly can be made of different materials, which affects the service life. A double-circuit device has two heat exchangers, and a single-circuit device has one. There are three types of design:

- Steel. Economical option. Steel is resistant to temperature fluctuations, has low thermal conductivity, and a short service life.

- Copper. Copper is resistant to temperature changes and rust. The material conducts heat better than steel. Therefore, a copper heat exchanger is more expensive. Has a limited heating temperature.

- Cast iron. The alloy is resistant to rust and high temperature. Is an excellent heat conductor. Due to its heavy weight, cast iron is used for floor-standing appliances.

Circulation pump. Designed to create structural pressure and constant water circulation. Not available on all models.

Expansion tank. Used for security purposes. The expansion tank absorbs excess heat when the coolant is very hot.

Smoke exhaust. The drainage system is of open and closed type. In an open chimney, used gases escape through the ventilation system. Turbine burners are of the closed type. The chimney air is supplied through the room without an auxiliary mechanism. The turbine burner has special pipelines for drawing air from the room.

Electronics. Includes control module, sensors, wiring, circuits. These elements allow the equipment to operate stably.

Operation of the gas boiler automation system

The automation system consists of sensors that ensure safe operation, control and maintain the set coolant temperature. Automatic safety allows you to stop the gas supply if the gas is turned off. During further operation, you must manually restart the system.

REFERENCE! Modern equipment is equipped with additional sensors and thermostats that provide energy-saving and anti-frost modes. Some also have self-diagnosis, which analyzes the state of the main components and displays detected faults on the screen. This system avoids malfunctions.

Types and classification of gas boilers

The operating principle of the equipment depends on the type and classification. For proper operation, you need to know the type of equipment.

According to the installation method, there are two types:

- wall-mounted, suitable for a small room;

- floor-mounted, suitable for large areas, simultaneously heats and provides hot water.

By type of chimney there are:

- open or atmospheric;

- closed or turbocharged.

By functionality:

- single-circuit with one radiator;

- double-circuit with two radiators.

By type of burner:

- simulated with automatic flame adjustment;

- normal, no adjustment.

By type of ignition:

- piezo ignition is started by pressing a button;

- electronic works automatically.

According to the principle of operation:

- convection includes the usual circuit, water coolant;

- Condensing uses conventional heat and the heat of water vapor.

The range of gas appliances is varied; to make the right choice, you should take into account all the nuances of further use and the area of the room.