Connecting the pump to the heating boiler

Of course, before installation it is necessary to decide on the area in which the actions will take place. Connecting the pump to the heating boiler requires certain knowledge. It is recommended to install after the boiler, that is, before the first branch.

The content of the article

Selecting the location for inserting the device into the system

If the house already has two branches (for example, on different floors), then two devices should be installed - on each separately. And also after the boiler. If one is directed upward, then much less fuel will be consumed, since the coolant will move less. There is no need to worry about damage to your stay as it is completely safe.

REFERENCE! Thanks to modern technologies and materials used in manufacturing, the device can easily withstand even the highest temperatures and is not afraid of water. Therefore, it can be installed both on the return pipeline and on the supply pipeline.

There are features that it is advisable to take into account:

- There should be no leakage above the selected location.

- It must be made accessible so that, if necessary, it is possible to carry out maintenance, preventative maintenance on the equipment or repair it.

- In addition to access for you, it should also be for the electrical network.

- The pump is positioned in the direction of movement of the coolant.

Installing a circulation pump in the heating circuit

In principle, the device works perfectly everywhere, regardless of the part of the heating circuit. But it is worth remembering the following when connecting to the boiler:

- The position of the bearing life determines the temperature of the carrier, that is, the lower the indicator of the first of them, the higher it is of the second.

- The tank, in turn, should be mounted so that it is close enough to laminar flow.

Basic rules for installing a circulation pump

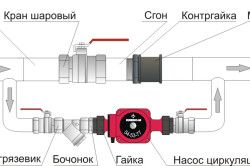

- The filter must cut in, as this protects the device from foreign particles.

- Carry out some steps to ground the outlet into which the device will be connected in the future. This should be done for your own safety.

- To avoid leaks, use sealant on threaded connections.

- When installing, follow the arrow. It moves in the direction of the coolant.

- Give fixation to the ball valves that are located on the sides of the structure.

- In order to increase the potential of work, it is necessary to carry out processing of all fasteners. In case of death, the surface of the unit faces various damages, and the whole process becomes meaningless.

- Observe the sequence of connections.

- There should be air valves on top of the bypass that remove air from the system.

How to install a pump for a heating system yourself

Once the location has already been selected, you can begin to install the device itself. The coolant must first be drained if the installation will take place in an existing network.During long-term use, it is necessary to clean it from possible blockages. To do this, run water through it several times.

The montage must be reproduced at the cutting location. This is done in accordance with the heating plan. After that, you need to connect the pump to the heating system - fill it with heating and water. Check the functionality, because it is better to detect defects at this stage, and if there are any, correct them. The next step involves removing excess air by opening the central screw, which appears on the housing cover. If the outcome is correct, you will notice water, this will mean that the air mass has been eliminated, which means that your actions are correct.

The montage must be reproduced at the cutting location. This is done in accordance with the heating plan. After that, you need to connect the pump to the heating system - fill it with heating and water. Check the functionality, because it is better to detect defects at this stage, and if there are any, correct them. The next step involves removing excess air by opening the central screw, which appears on the housing cover. If the outcome is correct, you will notice water, this will mean that the air mass has been eliminated, which means that your actions are correct.

ATTENTION! To ensure long-term operation of the unit, you can purchase an automatic pump.

Network connection

It is this pump that needs to be connected both to the differential machine and to the thermostat. There are also two more ways: connecting at the same time with an uninterruptible power supply unit, and using boiler automation.

- As for the scheme of the first of them, this is the best option, very simple and easy to use. You will only need wires, a differential switch (8A) and contacts. The first step is to cut the cable to the desired length and pull it through the corrugation. Together they are routed through the shield to the pump. The cable is connected using a phase wire (to L), and to N - neutral. It remains to connect the ground to the PE terminal.

- To automatically stop movement at low temperatures, a circulation pump with a thermostat is used. When cooling occurs, the power supply circuit is broken.For this to happen, you need to attach a thermostat to the pipeline. Also, it is best to connect it to a metal section of the highway so that it provides reliable information.