DIY pyrolysis boiler

Pyrolysis is the name given to the process in which fuel burns slowly. It is accompanied by the formation of a gaseous environment.

Pyrolysis is the name given to the process in which fuel burns slowly. It is accompanied by the formation of a gaseous environment.

This process underlies the operation of boiler equipment, which in its efficiency can be comparable to gas.

It is not necessary to buy a pyrolysis boiler: you can make it yourself. Below we will tell you in more detail how to do this.

The content of the article

The originality and peculiarity of the operation of pyrolysis boilers

Advantages of boilers

Boilers based on pyrolysis have a number of the following advantages.

- When fuel burns, there is no release of soot, soot and other combustion waste. Pyrolysis furnaces are one of the most environmentally friendly types of furnace equipment.

- Any dry fuel can be used as fuel, for example, sewing waste. Good quality fuel can ensure continuous operation of a boiler based on a pyrolysis furnace for 12 hours. That is, loading firewood can be done twice a day.

- Using such a stove allows you to reduce utility heating costs by 50–60% per year.The use of pyrolysis technology makes it possible to automate furnace control processes, and this accordingly increases the safety of the device as a whole.

Flaws

Meanwhile, boilers of this type also have certain disadvantages.

To purchase a finished boiler and put it into operation, you will need to invest a certain amount, but it is also worth noting that the efficiency of this device will be visible almost immediately.

Features of operation

One of the difficulties in operating such a device is due to the fact that the fuel that will be used must have a moisture content of about 20%. Otherwise, the combustion will stop. That is, the fuel must go through a drying procedure. This operation may add complexity to the device and reduce its performance.

In some cases, a pump powered by electricity is used to pump air, and the operation of the equipment becomes dependent on electricity.

This information must be kept in mind when starting to make your own boiler.

Materials and tools for manufacturing

Before you start creating a furnace of this type, you need to collect a fairly wide range of tools and materials.

Below is a sample list.

- Electric drill.

- Welding machine. Experience suggests that it is advisable to use a direct current model.

- Electrodes for welding work.

- Angle grinder.

- Cutting and grinding wheels with a diameter of 125 mm. If you cut the sheet for making the stove yourself, you will need a cutting wheel with a diameter of 230 mm.

The material for the manufacture of the furnace is usually given in the specification included in the set of working documentation.But in any case, a sheet with a thickness of 4 mm, profiled pipes with a wall thickness of 2 mm, and a certain amount of strip metal with different widths and thicknesses will be in demand. In addition to the metal from which the oven will ultimately be constructed, you will need a fan and a temperature sensor.

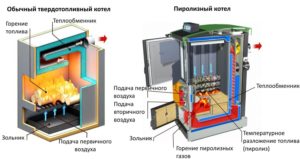

Important! A pyrolysis boiler differs from other equipment in that it burns not only fuel, but also the gas released during its combustion.

Scheme and drawings of a pyrolysis boiler

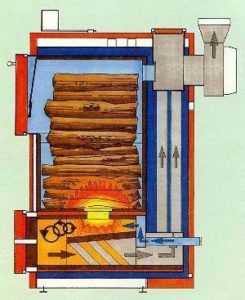

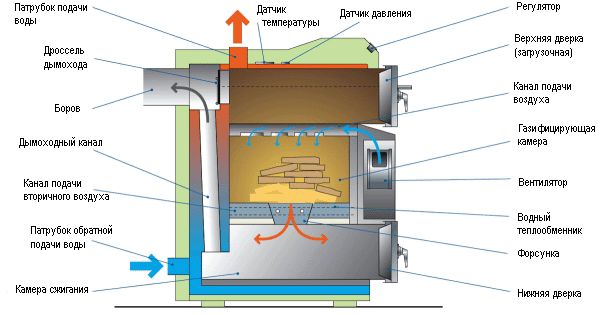

To better understand the operating principle of this equipment, it makes sense to understand how such a boiler works and disassemble its circuit diagram.

The pyrolysis furnace consists of the following parts.

- Gasification chambers.

- Afterburners.

- Air supply systems (primary, secondary).

- Water shirt.

- Grate.

In addition, the design of a pyrolysis boiler includes pipes for water supply, a combustion chamber, control equipment, a fan and some other components.

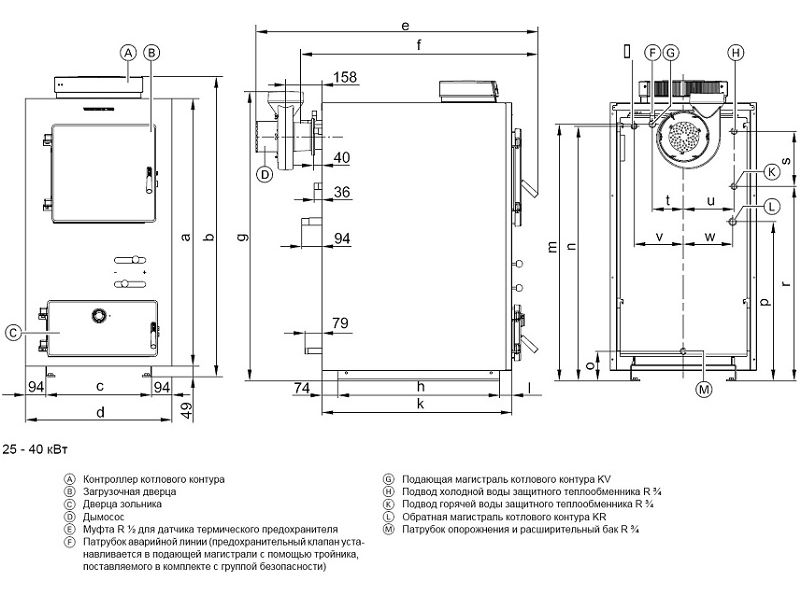

A pyrolysis boiler is a rather complex technical device. When producing it yourself, you must strictly comply with all the requirements of the working documentation.

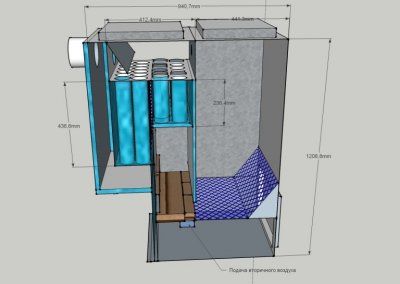

We offer a drawing of the boiler, which will be useful during manufacture.

The following diagram will help you understand the internal structure of the boiler.

As a rule, a boiler with a capacity of 40 kW is sufficient to heat a country house. If this indicator needs adjustment, then you can change some oven parameters.

In order to make a boiler, it is necessary to prepare its main structural elements.

Step-by-step instructions for making a pyrolysis boiler

Frame

Sheet steel is used to make the body of a long-burning boiler.

- Using an angle grinder, parts are prepared in accordance with the received drawings.

- Places are prepared in the walls for the ash pit doors and for loading fuel. The main thing when performing work is compliance with all requirements of the working documentation.

- A welding machine is used to connect sheet parts.

- After receiving the finished parts, the resulting seams must be cleaned of scale. To do this, use a small angle grinder with a grinding wheel installed.

- After this, the pipes are welded so that there are no gaps between the seams.

- A protective heat exchanger must be installed on the rear wall of the boiler.

- After it has been tested for leaks, a back wall made of heat-resistant steel can be installed.

- At the next stage of furnace manufacturing, it is necessary to install a partition that will separate the gasification and gas combustion chambers by making a grate made of cast iron.

- An air duct along with a damper is installed on top of the gasification chamber. An air duct is installed at the bottom of the chamber. After this, the firebox is immediately finished with fireclay (heat-resistant) bricks.

- Finishing is done on the bottom and sides.

Doors

For the boiler doors you will have to buy a sheet of heat-resistant steel.

To increase rigidity, they are reinforced with a steel angle, welding it to the inside.

Assembly

Such a boiler can be installed in non-residential premises.

Assembly is carried out in the following order.

- Attach the chimney.

- After this, pipes are attached to the boiler, through which the working fluid of the heating circuit will be transported.

- The installation is considered complete after installing the smoke pump.

Tips for making a pyrolysis boiler

- When manufacturing this equipment, it is necessary to strictly comply with the requirements of working drawings, and the work itself must be performed using high-quality tools.

- Since a grinding machine will be used during the work, when processing welds it is necessary to use personal protective equipment: goggles, gloves, a respirator.

- All work must be carried out in compliance with safety and labor protection requirements.

- Upon completion of work, it makes sense to apply a protective coating to the surface of the finished furnace to protect the furnace from corrosion.

- When making or purchasing a finished chimney, you must pay attention to the fact that it is made with a minimum number of bends. This will facilitate the passage of combustion products.

- A boiler operating using pyrolysis must be installed on a solid base. It is necessary to install a simple foundation under it, which does not need to be buried. It is enough to pour a flat area of concrete.