Solid fuel boiler piping

Heating private homes is of increasing interest among residents of the private sector, not only in villages, but even in large cities. Energy prices are constantly rising, and the economic crisis is forcing home owners to think about the efficiency of heating methods for their own buildings.

This article is intended for those who want to understand the wide variety of heating methods for residential buildings and, when choosing their own system, take into account the pros and cons of each of them.

The content of the article

How to connect a solid fuel boiler

Connecting a solid fuel heating boiler, the circuit of which is quite complicated for a beginner, requires familiarizing yourself with an overview of the energy resources that are present on the market today and the heating systems that operate on them.

Connecting a solid fuel heating boiler, the circuit of which is quite complicated for a beginner, requires familiarizing yourself with an overview of the energy resources that are present on the market today and the heating systems that operate on them.

- Natural gas is one of the most common energy carriers in the gasified part of the country. The advantages include the ability to create an automatic heating system that would not require human participation;

- Electricity is an equally common method of heating, but it requires a fairly powerful power supply to the house, preferably three-phase.And this condition is not always ensured, especially in rural areas;

- Coal, firewood and other fuels for solid fuel boilers require fairly frequent human presence and are difficult to automate. Heating automation is quite expensive;

- The sun, wind, and geothermal sources today are often exotic sources of energy and are available only to the wealthy.

If we talk about methods of coolant circulation, there are only two of them:

- Forced circulation;

- Natural circulation.

How to connect a solid fuel boiler to a heating system? Each of these methods has its own advantages and disadvantages. To choose one of them, you need to carefully weigh the possibilities of their use in certain situations. Let's take a closer look at each of them.

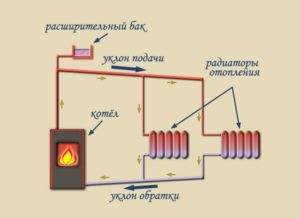

Scheme of operation of a natural circulation system

The simplest way to construct heating methods, the boiler piping is minimal. The advantages include:

The simplest way to construct heating methods, the boiler piping is minimal. The advantages include:

- Work without the use of electric pumps. That is, even if the power is completely turned off, the system will heat the room.

- Low cost of equipment.

- Easy to set up and maintain.

The disadvantages of installing solid fuel boilers include:

- Low efficiency and, accordingly, excessive fuel consumption.

- It is impossible to control the combustion and circulation process; the heating operates in manual control mode.

Scheme of operation of a forced circulation system

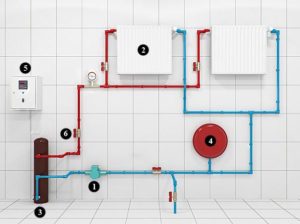

Pumps are used to pump coolant through pipes. Tying such a system is much more complicated and expensive. The advantages of the system include:

Pumps are used to pump coolant through pipes. Tying such a system is much more complicated and expensive. The advantages of the system include:

- High efficiency;

- Coolant temperature adjustment;

- Possibility of using automation;

- Possibility of using emergency and fire protection systems.

The disadvantages of such systems include:

- Impossibility of working without electricity;

- High cost of equipment.

Attention: An emergency shutdown of electricity can lead to equipment overheating and failure. Therefore, a backup power source is required.

There are not so many types of coolants. The most common is plain water. But when heated, scale forms in the pipes, and if it is drained from time to time, rust forms.

It is more expensive to use natural or mineral oil, such as spindle oil, as a coolant. But this method is quite expensive, although more effective.

How to make a harness cheaper

How to tie a solid fuel boiler with a closed system? The boiler piping is a set of various elements that ensure reliable and uninterrupted operation of the boiler and the delivery of coolant in a given quantity and the required temperature to the radiators in the premises.

How to tie a solid fuel boiler with a closed system? The boiler piping is a set of various elements that ensure reliable and uninterrupted operation of the boiler and the delivery of coolant in a given quantity and the required temperature to the radiators in the premises.

As a rule, piping a boiler costs much less than the boiler itself, and what is even more important is the comfortable conditions that it creates during the cold season. But when drawing up a piping diagram for solid fuel boilers, there is a temptation to save money not on the boiler, but on its piping, but you should understand the following:

- Buying cheaper harness elements leads to a decrease in reliability, especially if these elements are made in China;

- Simpler strapping methods reduce the efficiency of the system;

- If an emergency or extreme situation occurs, the equipment may be damaged.

When connecting a solid fuel boiler to a heating system, the piping elements can include several elements. Depending on the method of organizing the boiler equipment, the piping configuration may differ.But as a rule, certain strapping elements are required. These include:

- One or more pumps depending on the complexity of the system;

- Expansion tank;

- Three-way valve;

- Security group;

- Filters;

- Drain and ball valves.

How to properly wire a solid fuel heating boiler, what should the diagram be? Elements such as an expansion tank and a pump will be present in any scheme. But some elements are necessary for more convenient startup and maintenance of equipment, so their presence in the system is not necessary, but desirable. One of the optional elements of the system is a heat accumulator. Let's look at its operating principle and purpose.

How to connect two boilers

The heating scheme for a private house with a solid fuel boiler assumes the presence of a backup device. In the event of a failure of the main boiler or its transfer to routine maintenance, it is desirable that the backup boiler be switched on automatically. The appropriate piping of such a boiler should automatically disconnect the heating equipment from the main boiler and connect the backup one.

The heating scheme for a private house with a solid fuel boiler assumes the presence of a backup device. In the event of a failure of the main boiler or its transfer to routine maintenance, it is desirable that the backup boiler be switched on automatically. The appropriate piping of such a boiler should automatically disconnect the heating equipment from the main boiler and connect the backup one.

Important: The wiring diagram of a solid fuel boiler with a circulation pump does not indicate that there is a need to install a backup boiler with the same power as the main one, since its task is to keep the system in working order until the main boiler is started. Typically, such equipment is installed in rooms where uninterrupted heat supply is given special attention.

Connecting a solid fuel boiler with a heat accumulator

How to connect a solid fuel heating boiler with your own hands? A heat accumulator is usually called an additional container for coolant in which it can be stored for a long time and used to heat a room.It is an insulated thermos that can store one ton or more of coolant. The wiring diagram for a solid fuel boiler using a heat accumulator is one of the most complex.

How to connect a solid fuel heating boiler with your own hands? A heat accumulator is usually called an additional container for coolant in which it can be stored for a long time and used to heat a room.It is an insulated thermos that can store one ton or more of coolant. The wiring diagram for a solid fuel boiler using a heat accumulator is one of the most complex.

The connection diagram of the solid fuel boiler to the heating system is such that the system automatically selects the direction of movement of the hot coolant. There can be two options:

- In convectors located indoors;

- Into the heat accumulator.

The connection diagram of a solid fuel boiler is such that at the beginning of operation the heat accumulator is heated to a given temperature, and only then it switches to heating the premises itself.

The advantages of installing a solid fuel boiler in a private home include the following points:

- High efficiency of heat transfer from the boiler to heated rooms;

- Long time for heating the room even when the boiler is turned off;

- Possibility of creating a system for supplying premises with hot water without additional heating devices.

The disadvantages of piping a solid fuel heating boiler in a private house are:

- Large financial costs for organizing the piping of the boiler with a heat accumulator;

- Electricity is required to operate the equipment.

Piping the boiler with a heat accumulator

The wiring diagram for a solid fuel boiler with a heat accumulator assumes the presence of a three-way one. With its help, two heating circuits are created. The first is between the boiler and the heat accumulator and the second is between the heat accumulator and the heating devices of the house. A three-way valve controls the switching on and off of these circuits to efficiently heat the room. The wiring diagram for a solid fuel boiler with a battery tank is not complicated.

The wiring diagram for a solid fuel boiler with a heat accumulator assumes the presence of a three-way one. With its help, two heating circuits are created. The first is between the boiler and the heat accumulator and the second is between the heat accumulator and the heating devices of the house. A three-way valve controls the switching on and off of these circuits to efficiently heat the room. The wiring diagram for a solid fuel boiler with a battery tank is not complicated.

Trim with buffer tank

Piping diagram for a solid fuel boiler with a buffer tank: one of the mandatory elements of the heating system piping, the purpose of which is; maintain constant pressure in the heating system at changing coolant temperatures. The piping of a solid fuel boiler with a buffer tank is usually calculated in the amount of ten percent of the total coolant volume.

Piping diagram for a solid fuel boiler with a buffer tank: one of the mandatory elements of the heating system piping, the purpose of which is; maintain constant pressure in the heating system at changing coolant temperatures. The piping of a solid fuel boiler with a buffer tank is usually calculated in the amount of ten percent of the total coolant volume.

Connecting boilers with different energy sources

Since energy costs and availability are constantly changing, many homeowners have installed boiler rooms with multiple boiler power sources. The wiring diagram for a solid fuel heating boiler with a heat accumulator usually involves the presence of gas and electric boilers, which allows them to be used at the most appropriate time.

Since energy costs and availability are constantly changing, many homeowners have installed boiler rooms with multiple boiler power sources. The wiring diagram for a solid fuel heating boiler with a heat accumulator usually involves the presence of gas and electric boilers, which allows them to be used at the most appropriate time.

Features of connecting emergency systems

These elements of boiler equipment are designed to operate in emergency conditions, such as a power failure in a boiler room with a working solid fuel boiler that cannot be extinguished instantly. Such systems will allow cooling of the coolant until electricity appears. Or they will automatically turn on the backup power source, and the system will continue to operate as normal.

These elements of boiler equipment are designed to operate in emergency conditions, such as a power failure in a boiler room with a working solid fuel boiler that cannot be extinguished instantly. Such systems will allow cooling of the coolant until electricity appears. Or they will automatically turn on the backup power source, and the system will continue to operate as normal.