Tying a heating boiler with polypropylene schemes

Proper piping of the heating boiler is the key to long-lasting and efficient functioning of the heating system. Most often, polypropylene pipes are used for these purposes, since they are inexpensive and easy to install - their connection is made with a soldering iron, and there are guaranteed to be no leaks. Despite the apparent simplicity, there are certain requirements and compliance with the technology for performing the work. They may come as a surprise to an inexperienced person, because neglecting them can lead to disastrous consequences.

Proper piping of the heating boiler is the key to long-lasting and efficient functioning of the heating system. Most often, polypropylene pipes are used for these purposes, since they are inexpensive and easy to install - their connection is made with a soldering iron, and there are guaranteed to be no leaks. Despite the apparent simplicity, there are certain requirements and compliance with the technology for performing the work. They may come as a surprise to an inexperienced person, because neglecting them can lead to disastrous consequences.

The content of the article

Why do you need a heating boiler piping and what is it?

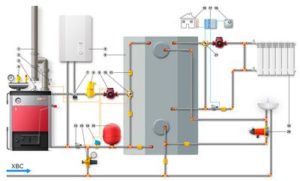

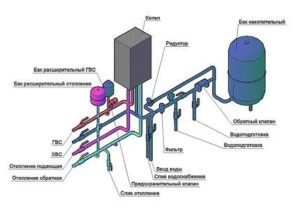

A piping is a set of equipment whose task is the uninterrupted operation of the heater and further transportation of the coolant to the radiators. The operation of the boiler, maintaining a comfortable temperature in the rooms and the reliability of the system as a whole depend on it, which is why the circuit requires accurate preliminary calculations. This is also due to the fact that there is no universal scheme that would be equally effective for all systems. For maximum efficiency of the heating network, the design is carried out individually, but in any scheme the following must be present:

A piping is a set of equipment whose task is the uninterrupted operation of the heater and further transportation of the coolant to the radiators. The operation of the boiler, maintaining a comfortable temperature in the rooms and the reliability of the system as a whole depend on it, which is why the circuit requires accurate preliminary calculations. This is also due to the fact that there is no universal scheme that would be equally effective for all systems. For maximum efficiency of the heating network, the design is carried out individually, but in any scheme the following must be present:

- single-circuit or double-circuit boiler;

- expansion tank;

- polypropylene pipes, fittings;

- batteries made of preferred material;

- bypasses to turn off certain devices, if necessary.

It is not without reason that polypropylene pipes have become so widespread. PIn addition to the fact that the structure using them is monolithic, it is resistant to heat, high speed of installation and its simplicity, low thermal conductivity, versatility and the absence of plaque accumulation on the internal walls. By choosing this material, you can be confident that the system will function properly for decades.

Methods for piping heating boilers

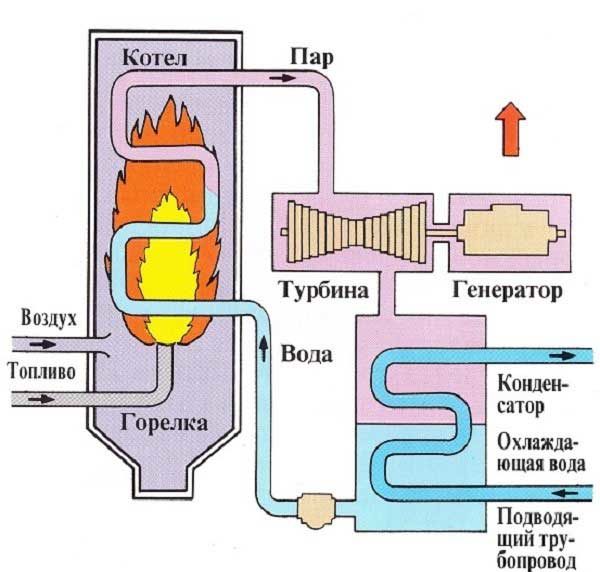

Depending on the principle of fluid circulation along the circuit, systems come with forced and natural movement. The latter is characteristic of the simplest heating schemes, in which the movement of hot and cold water occurs due to gravity. This makes it suitable for small buildings, but its use in large and multi-story buildings is unacceptable. Due to the fact that the effectiveness of such a piping cannot be influenced, a pump is often installed into it, which is used when necessary. The advantages of this type of heating include:

Depending on the principle of fluid circulation along the circuit, systems come with forced and natural movement. The latter is characteristic of the simplest heating schemes, in which the movement of hot and cold water occurs due to gravity. This makes it suitable for small buildings, but its use in large and multi-story buildings is unacceptable. Due to the fact that the effectiveness of such a piping cannot be influenced, a pump is often installed into it, which is used when necessary. The advantages of this type of heating include:

- ease of installation;

- uninterrupted operation due to independence from the power grid;

- low cost of installation and maintenance;

- absence of devices that can fail.

Disadvantages include the need for careful selection of pipe diameters, which affects the functionality of the circuit, as well as the aesthetics of the system, which is far from ideal.

The forced version is distinguished by the possibility of control and greater comfort, since the temperature can be adjusted individually for each room and maintained automatically.

ATTENTION! The functioning of the circuit directly depends on the electrical network and in the absence of electricity its operation is simply impossible.

In this case, the piping will be complex and involve the insertion of expensive equipment that requires regular maintenance. In addition, the devices will need to be balanced and installed by experienced craftsmen, whose services are not cheap. It is possible to use the principle of primary-secondary rings, due to which the number of devices in the network is reduced. Each ring will require a circular pump to ensure an even flow of coolant.

Schemes for various boilers

The versatility of polypropylene pipes makes it possible to use them for all types of coolant. They are resistant to corrosion and have smooth internal walls, which guarantees cleanliness throughout their entire service life.

IMPORTANT! Experts recommend using a metal pipe when installing the first meter of pipeline, and then connecting polypropylene to it. This is due to the fact that if the boiler malfunctions, a thermal shock is possible, which will cause the piping to burst.

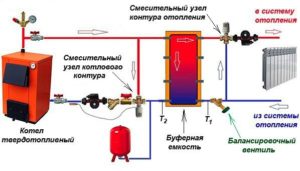

Solid fuel boilers

It differs in that the heating of the coolant will continue until the fuel in the firebox burns out completely, and this is unfavorable for polypropylene. In this regard, the use of metal when arranging the first meter of piping is mandatory and only polypropylene pipes should be connected to it.

It differs in that the heating of the coolant will continue until the fuel in the firebox burns out completely, and this is unfavorable for polypropylene. In this regard, the use of metal when arranging the first meter of piping is mandatory and only polypropylene pipes should be connected to it.

General recommendations:

- installation of an uninterruptible power supply is required for uninterrupted circulation, since heat must be constantly removed by the pump, despite electrical problems;

- It would not be superfluous to equip all batteries with bypasses, which will facilitate repairs in the event of a breakdown without the need to turn off the heating system;

- The solid fuel boiler must be covered with a protective casing that limits the heating of the boiler room; in addition, the maximum distance from the firebox to the collector and pipes must be ensured.

REFERENCE! Professionals advise making sure to install an additional water supply and drain it into the sewer system. This is necessary for efficient cooling of the heat exchanger.

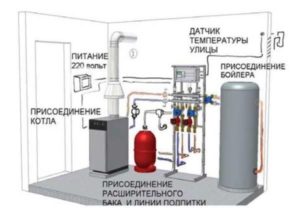

Gas boilers

For these models, the piping is performed with a manifold and a hydraulic arrow. Gas boilers are most often used in forced heating systems and are equipped with a built-in pump. From a safety point of view, it is advisable to install circulation equipment for the circuits behind the collector. In this case, the pump builds up pressure to the distributor, and then additional pumps are turned on, which play a key role in pumping hot water. A cast iron heat exchanger in conjunction with a gas boiler will require installation in a heat accumulator system to smooth out temperature changes in the water that have a detrimental effect on cast iron. For double-circuit models with parallel heating, the installation of cleaning filters will be required at the inlet to the water heater.

Boilers for liquid fuel and electricity

The piping is carried out according to the scheme used for solid fuel heaters - the maximum distance to the plastic pipes must be ensured. The latter are perfectly combined with electric boilers due to the automation that prevents the coolant from heating to an excessively high temperature. To avoid water hammer, the systems are equipped with overpressure relief valves and a hydraulic accumulator.

The piping is carried out according to the scheme used for solid fuel heaters - the maximum distance to the plastic pipes must be ensured. The latter are perfectly combined with electric boilers due to the automation that prevents the coolant from heating to an excessively high temperature. To avoid water hammer, the systems are equipped with overpressure relief valves and a hydraulic accumulator.

Most often, when installing polypropylene pipes, welding (hot or cold) is used. In the case of hot soldering, a soldering iron is used to soften the parts, which, when connected, form a monolithic structure.A threaded connection is simpler, but the cost is several times higher than a welded one.

IMPORTANT! At the junction of polypropylene pipes with metal ones, it is necessary to use exclusively the threaded method. We should not forget about sealing the joint.

Thus, piping the boiler with polypropylene pipes is not very difficult and is quite feasible even for an inexperienced craftsman. The key to successful work is simple - competent calculation, analysis of all the features of the building and following the advice and recommendations of professionals.