Gas boiler does not turn on

Gas boilers are the most economical, easy to install and operate. It is for these reasons that heat generators are used in heating systems. But, like any technical equipment, boilers sometimes break down, and the most common failure is burner extinguishing. To understand the causes of the problems, you need to get to know them in more detail.

Gas boilers are the most economical, easy to install and operate. It is for these reasons that heat generators are used in heating systems. But, like any technical equipment, boilers sometimes break down, and the most common failure is burner extinguishing. To understand the causes of the problems, you need to get to know them in more detail.

The content of the article

Why the gas boiler does not turn on: the main reasons

Heating equipment that runs on gas fuel comes in different models:

- parapet;

- chimneys with an open combustion chamber;

- turbocharged.

Equipment failure occurs for several reasons.

If a gas boiler goes out, there may be insufficient gas pressure in the pipes due to a malfunction in the distribution network. More often the pressure drops if the meter is faulty. In this case, there is no gas flow through it. A breakdown is indicated by sounds uncharacteristic of this part, as well as significantly low pressure inside the boiler.

Modern units are usually equipped with displays that display an error code determined by a self-diagnosis system, for example, in the Valliant, Baxi, Ferroli models. If there is no message on the display indicating the error code, you will have to look for the breakdown yourself.

The main malfunctions of gas equipment:

- the boiler does not turn on or turn off;

- the flame in the burner goes out;

- temperature does not rise.

Reasons why the boiler does not turn on

If the heating equipment does not light up at all, the reasons include the following factors:

- the ignition system has failed;

- the gas supply is stopped or the tap on the pipe supplying it is closed;

- too low or high gas pressure inside the pipe;

- The burner nozzle is clogged.

If it doesn't light up the first time

Failures of a gas heating unit, in which case they light up immediately, are caused by various factors. External:

- too low gas pressure level in the main pipeline;

- problem with the functioning of the chimney;

- voltage fluctuations;

- draft or low temperature inside the building where the boiler is located.

Internal ones include failure of electronics, pump, heat exchanger.

If the unit goes out and then does not immediately light up, the cause of this phenomenon may be a lack of ventilation in the room. This often happens with heating devices “Proterm”, “Navien”, etc., in which the combustion chamber is open. They take combustion air from the room.

Other faults

When the pressure in the line drops, the dual-circuit devices “AOGV” or “Vailant”, for example, are switched off. This also happens when the fuel supply fluctuates. If the igniter is incorrectly adjusted, the protection is triggered and the boiler stops working.

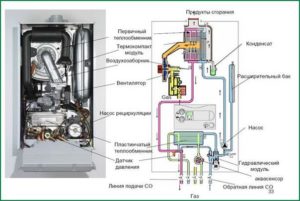

To determine other faults, knowledge of the device that requires repair is required. Each model has its own distinctive features. But more often than not, components, sensors or circulation pumps break down for all brands.If such a pump fails, the burner will not turn on and the boiler will not be able to supply hot water and heating. It happens that the pump hums, but there is no work. It's quite possible it's jammed.

Sometimes the whole house can hear how loud and hard the boiler is working. This is most often caused by a large amount of scale in the heat exchanger. This factor often leads to overheating of the heat exchanger.

Injectors can also make a whistling noise. This happens when the boiler is ignited. A whistle indicates the presence of air in the gas pipeline. To eliminate the whistling, it is enough to release the air.

If water or condensation gets on the main board, irreparable damage occurs inside it. If the cause is moisture, streaks are visible on the board.

Attention! For long service life of gas equipment, the board must be protected from water leaks and steam ingress.

How to solve a problem like this

Modern heating equipment that runs on gas fuel is equipped with a special control board with an information display or indicators. If there is no indication, you need to check whether power is supplied to this control panel. As a rule, the boiler is connected to the network through a separate channel, so it must be checked first to see if it is disconnected. You can verify this using a multimeter: the voltage on it should be 220V in the place where it is connected to the board. If there is no voltage, you need to localize the problem. Sometimes it is enough to insert a pulled plug into the socket.

There is also no voltage supplied to the panel due to the failure of the fuses.

If the device does not turn on due to poor ventilation, you must:

- organize good ventilation;

- install valves on window packages;

- open the window in the room with the boiler to ensure air flow

Important! Before turning on the boiler, you need to check whether there is draft inside the chamber. For this purpose, light a match and bring it to a window or chimney branch. If draft is present, the flame will deviate in the direction of air movement. And if it is absent, the flame of the match will be even.

If the device does not turn on the first time, you need to check the pipes for gas leaks, for which they are lubricated with a soapy foam layer. Bubbles will appear where there is a leak. In this case, it is necessary to turn off the valves, open the window and call the emergency gas service.

Something to remember! It is unacceptable to look for a gas leak by inspecting the pipe with an open flame (matches, lighter). A soap solution is required.

If the meter fails, its readings do not change, and noise is heard. You cannot eliminate such a malfunction on your own. A master is needed here.

Problems with improperly functioning traction leading to automatic shutdown of equipment. To prevent such phenomena from occurring, during installation it is necessary to take into account the requirements for the standard height of the chimney: it must be at least 50 cm above the ridge and at a distance on the roof of more than 1.5 m from it. Compliance with these conditions will avoid problems with traction operation.

Gas equipment is not equipped with a system that enhances draft, so in case of weak draft or its absence, debris gets into the chimney.

If the pump is jammed, the boiler should be stopped and the problem should be repaired.

If an attempt to turn on the boiler occurs after a long shutdown, you can use antifreeze as a coolant. It doesn't freeze if the temperature is too low.This will allow the system to start up after being idle.

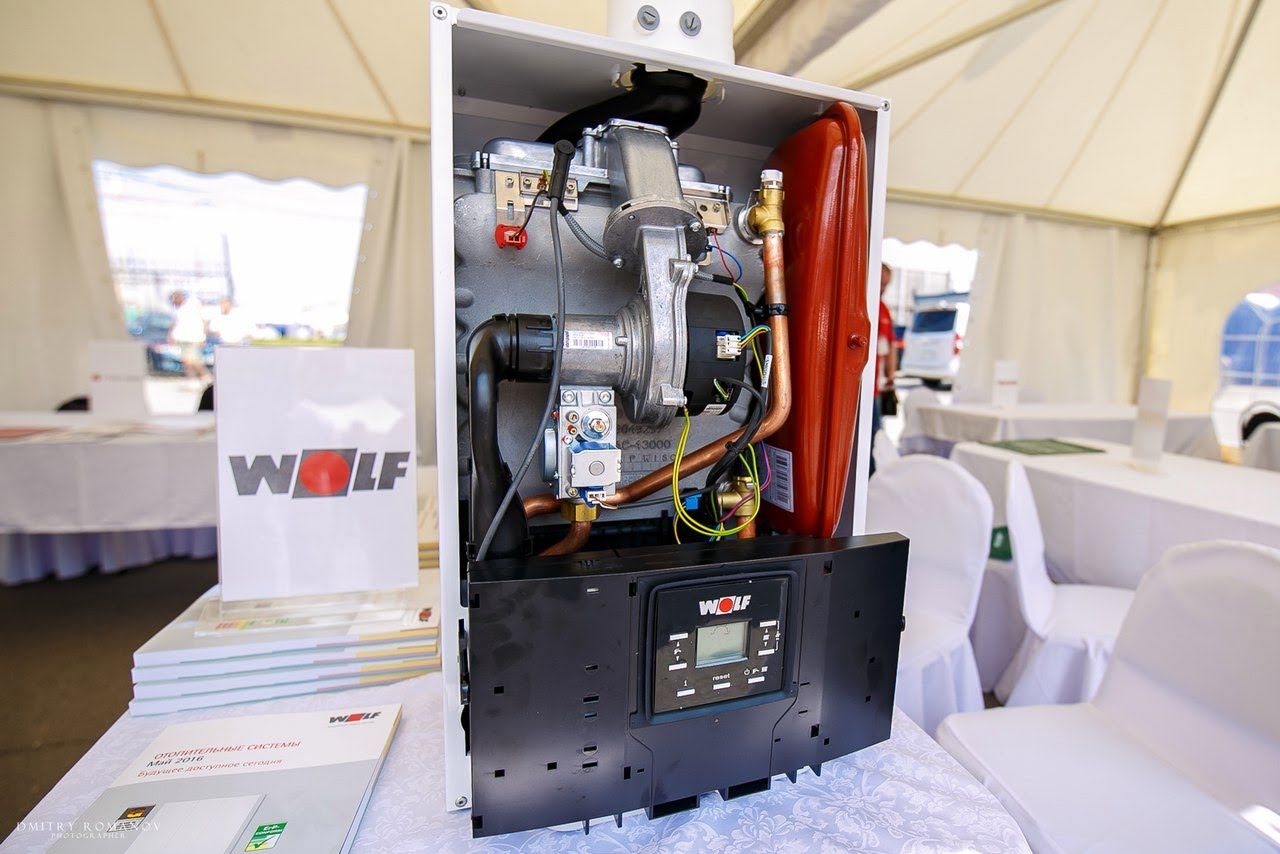

All boilers with a closed combustion chamber (for example, Buderus, Wolf and some other models) have fans installed. They are designed to remove combustion products. If you hear sounds indicating a malfunction of their operation, diagnosing and replacing the element in case of breakdown will help.

If the boiler turns off and does not turn on, you need to check the burner nozzle to see if it is clogged. The part is cleaned of dirt, the photocell of the sensor is cleaned, and then the procedure for turning on the device is repeated. Diagnostics and replacement are also carried out in case of breakdown of the thermocouple, pressure and draft sensors.

The remote control is also checked, batteries are replaced, and the display is inspected. If the remote control does not work, the controller is diagnosed.

Sometimes, when starting up gas equipment, you cannot hear its operation (noise) and you smell gas, although other appliances (stove or gas water heater) are functioning normally, and the temperature outside is above +10 degrees Celsius. The cause may be a clogged igniter, because not enough gas passes through the nozzle.

There are problems with turning on the heating if the quality of the gas supplied to the boiler is extremely low.

If the noise is caused by scale, the boiler is adjusted to maximum heating. If the noise intensifies, the cause is definitely scale. Then it is necessary to add a chemical that dissolves scale to the heat exchanger and rinse it.