DIY wood burning boiler

Despite the fact that our country is implementing a mass gasification program, wood-burning heating appliances have not lost their relevance. To this day, even in luxury country houses you can find boilers that burn wood.

Despite the fact that our country is implementing a mass gasification program, wood-burning heating appliances have not lost their relevance. To this day, even in luxury country houses you can find boilers that burn wood.

The content of the article

Features of manufacturing long-burning wood-burning boilers

Boiler equipment that runs on wood is a fairly popular way to provide autonomous heating for buildings and structures of various types. It is quite possible to make such devices yourself, This will require knowledge of welding, tools and a drawing.

How to make a wood-burning boiler for water heating with your own hands

Independent production of a wood-burning boiler for heating will require the master to carry out some preparatory measures. In particular, you will need to draw a sketch of the future product. He can imagine the upcoming scope of work and draw up a list of necessary materials and tools.

IMPORTANT!

TO MANUFACTURE THE BOILER CASING, IT IS APPROPRIATE TO USE STRUCTURAL STEEL WITH A THICKNESS OF 3–5 MM.THE USE OF SHEETS WITH A LOWER THICKNESS CAN LEAD TO DEFORMATION OF THE STRUCTURE ARISING OUT UNDER INFLUENCE OF HIGH TEMPERATURE.

Before starting assembly, except for the sketch you will need to calculate the slope, under which pipes supplying coolant and hot water will be installed. In addition, the homeowner must determine the location where the boiler will be installed. It must meet fire safety requirements. In particular, it is necessary to install heat-insulating gaskets between the boiler and the walls of a wooden building, and a sheet of metal will need to be laid on the floor in front of the firebox. An expansion tank can be installed in the boiler room; a certain distance must be left between the boiler and the tanks.

Before starting assembly, except for the sketch you will need to calculate the slope, under which pipes supplying coolant and hot water will be installed. In addition, the homeowner must determine the location where the boiler will be installed. It must meet fire safety requirements. In particular, it is necessary to install heat-insulating gaskets between the boiler and the walls of a wooden building, and a sheet of metal will need to be laid on the floor in front of the firebox. An expansion tank can be installed in the boiler room; a certain distance must be left between the boiler and the tanks.

To remove combustion waste it is necessary install a chimney.

In addition to the places for installing the boiler and expansion tank, the homeowner must determine a place to store fuel.

In addition to the places for installing the boiler and expansion tank, the homeowner must determine a place to store fuel.

What you need for work

To make your own heating boiler, you will need the following materials:

- steel sheet 3–5 mm thick;

- steel pipes;

- pre-purchased doors, grate, damper.

For the manufacture of complex boilers, it may be necessary to have certain shut-off valves - taps, valves, etc. To ensure control over the operating parameters of the boiler, the installation of pressure and temperature sensors will be required. To ensure the movement of the coolant, the use of a circulation pump must be provided.

For the manufacture of complex boilers, it may be necessary to have certain shut-off valves - taps, valves, etc. To ensure control over the operating parameters of the boiler, the installation of pressure and temperature sensors will be required. To ensure the movement of the coolant, the use of a circulation pump must be provided.

The tool you will need:

- welding machine and electrodes;

- an angle grinder, it will be needed for cutting sheet metal and cleaning welds;

- ruler, tape measure, locksmith corner.

Work on assembling the stove must be carried out in a prepared place. That is, nothing should interfere with the work.

Step-by-step guide to making a wood-burning boiler with a water circuit

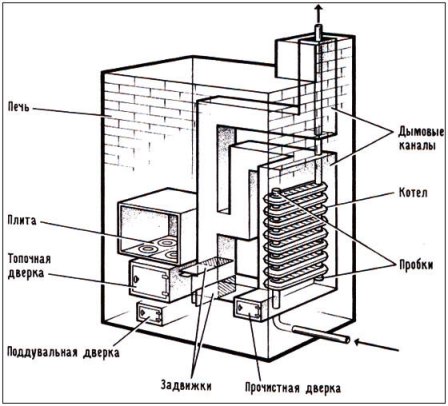

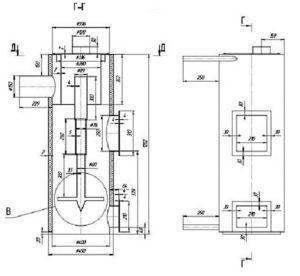

As an example, consider the manufacture of a boiler, which is shown in the figure.

Figure 1. Sketch.

The production of a boiler of this type can be divided into two phases.

- Making a firebox.

- Manufacturing of the body.

First of all, it is necessary to complete the preparations for making the boiler. To do this, you can use an angle grinder with a cutting wheel installed on it. But, cutting metal cannot provide the same quality of edges that cutting metal on mechanical shears (guillotine) can provide. Therefore, it makes sense to agree with the organization where the metal will be purchased about cutting the sheet to the required size.

When making a boiler from a sheet with a thickness of more than 4 mm, chamfering will be required on the edges. Their dimensions are defined in GOST; these data can be found in the mechanical engineering technologist's handbook. The presence of a chamfer will ensure the quality of the weld.

It makes sense to weld with an electrode with a diameter of 3–4 mm. The current strength is set on the control panel of the welding machine. It should be in the range of 180–200 A.

ON A NOTE!

WHEN PERFORMING THE WORK, YOU WILL NEED TO INVITE AN ASSISTANT, HIS TASK WILL INCLUDE HOLDING THE WORKS DURING WELDING.

Welding of sheets is carried out in two stages - first, a “tack” is performed and after checking, the sheets can be welded.

After welding, it is necessary to remove the slag and inspect them for quality of work.. There should be no bubbles, obvious lack of penetration, undercuts along the edges of the seam area or other defects on the surface of the seam.The quality of welds is defined in GOST 3242-79.

After welding, it is necessary to remove the slag and inspect them for quality of work.. There should be no bubbles, obvious lack of penetration, undercuts along the edges of the seam area or other defects on the surface of the seam.The quality of welds is defined in GOST 3242-79.

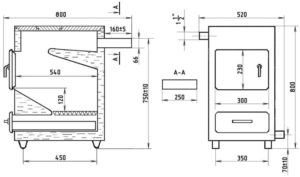

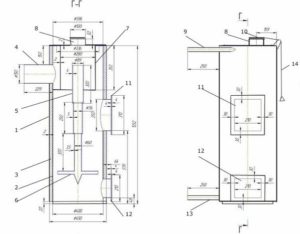

Drawings of options for making a wood-fired boiler

Engineering has no boundaries and therefore there are many different models of wood-burning boilers. Below are the most common boiler models used in households.

Important tips for making a wood-fired water boiler with your own hands

Not everyone can make a wood-burning boiler, but if you take it on, be careful and listen to the following tips:

Not everyone can make a wood-burning boiler, but if you take it on, be careful and listen to the following tips:

- If you do not have sufficient welding skills, entrust this work to a professional.

- Follow safety precautions when working with welding and metal.

- Before you start work, check the accuracy of the drawings - one small mistake can spoil the final result.

Overall, be careful and the results will be worth it.