DIY sauna boiler

It’s hard to argue with the fact that the boiler is one of the most important attributes in any bathhouse. Its main purpose is to achieve a certain air temperature, and also to create a special, unique atmosphere that can only be found in a bathhouse. The modern market offers a huge selection of boilers that operate on various types of fuel. If you want to save money, it’s quite possible to make a sauna boiler with your own hands.

The content of the article

How to make a cauldron for a sauna with your own hands

If you want to save money and have a desire to do something with your own hands, you can safely start making your own boiler for a sauna. There is nothing super difficult in this task; you will certainly cope with it. Pyou will need to prepare some materials and tools, draw drawings and you can start working.

What kind of boiler to make

In most cases, such designs come in two main types:

- Cylindrical.

- Rectangular.

It is easier to make the first design; to manufacture a rectangular boiler you will have to incur more significant financial costs, and labor costs will also increase, but they are more efficient in operation.

ADVICE. Before you start work, you need to prepare all the materials and draw drawings.For inspiration, you can look at photos of finished works.

Tools and materials

Most often, home craftsmen use metal pipes with fairly thick walls to assemble such structures. You can also use large-volume barrels. If you need a not very large and at the same time very compact boiler, prepare a pot one meter long and half a meter in diameter. From the tools:

- Metal welding machine.

- Angle grinder, the set will require special metal discs.

- Electrodes with a diameter of 3–4.

We use a metal pipe

Eat enough simple way, Can use Part pipes. This can be some piece of durable metal pipe; it must be of sufficient diameter, vertical and horizontal design is possible. Each of these methods has its pros and cons.

In order to assemble a horizontal boiler, a piece of pipe is placed in a horizontal position. A blind plug is installed on top. On the opposite side of this plug it is necessary to make a stove door. In order to additionally make a container for heating water, a jumper can be made near the plug. This container can also be placed in the upper section of such a stove. In order to increase the power of a homemade stove, you can make a heater in the side part, into which river stones will eventually be poured.

In order to assemble a horizontal boiler, a piece of pipe is placed in a horizontal position. A blind plug is installed on top. On the opposite side of this plug it is necessary to make a stove door. In order to additionally make a container for heating water, a jumper can be made near the plug. This container can also be placed in the upper section of such a stove. In order to increase the power of a homemade stove, you can make a heater in the side part, into which river stones will eventually be poured.

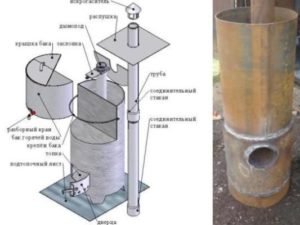

In order to assemble a vertical boiler, a piece of pipe is placed in a vertical position; perhaps this option will be more convenient and practical for you. In this case, the internal cavity of the pipe will be divided into two parts. At the bottom there is a firebox, and at the top there will be a tank for heating water. The hole for the stones can be made on the side.

The chimney pipe must be installed strictly in the center. All connections must be well welded. To increase the efficiency of such a stove, it is recommended to install an adjustable damper.

We use a metal barrel

This is a practical and economical method. The base is an old metal barrel.

IMPORTANT! New barrels are not suitable for such purposes. Since they are made of thin material.

It is necessary to cut out the top lid of the barrel. To do this, you can use a chisel and a hammer. Next, you will need to prepare a piece of metal pipe, this is about 15 cm for constructing the base of the chimney. Take another large barrel, about 200 liters in volume. Remove the bottom cover. In the center of this cover, make a hole with a diameter of 10 cm for the chimney pipe, then the pipe will need to be well welded. On the other hand, weld 4 sections from the channels.

From a metal sheet, cut out a lid for the boiler, which will be installed on top; it will also need a hole with a diameter of 10 cm. The assembled boiler is mounted to the chimney pipe.

IMPORTANT! Don't forget about insulating the boiler.

It is recommended to load such a boiler to no more than a third of its volume. Place a lid with a pipe on top of the firewood; it can be raised or lowered according to the height of the barrel. The structure must be covered with a top cover.

Long burn design

The most ordinary boiler, which runs on solid fuel, will operate on the firewood stored in it for no more than two to three hours. This seems like a lot, but often you want more. It is worth thinking about creating a boiler with a long-burning function.

This solution is undoubtedly very convenient. There is no need to add fuel regularly. To achieve the desired result, it is necessary to limit the air flow into the firebox.

REFERENCE! If a long-burning boiler is installed correctly, one load of firewood will burn for up to 20 hours.

The peculiarity of this design is very simple. The loading hatch should be located slightly above the middle of the body. It contains firewood that needs to be set on fire from above. An air restrictor should be installed above them; its conical edge rests on the firewood that will burn. When the firewood gradually burns out, this element will smoothly move down, which signals you to load a new batch of firewood.

The peculiarity of this design is very simple. The loading hatch should be located slightly above the middle of the body. It contains firewood that needs to be set on fire from above. An air restrictor should be installed above them; its conical edge rests on the firewood that will burn. When the firewood gradually burns out, this element will smoothly move down, which signals you to load a new batch of firewood.

REFERENCE. This scheme works and is effective due to the fact that the place where combustion occurs is limited by you and the fuel is gradually compressed, as a result of which the combustion processes occur more slowly.

By choosing this stove option, you can significantly reduce the amount of ash and soot produced when burning solid fuel. Now you know how to make boilers and you can safely build your own bathhouse.