Which chimney is better for a solid fuel boiler?

An integral part of an autonomous heating system is the chimney. Proper design and correct installation of a pipe for removing combustion products will help avoid the unpleasant smell of carbon monoxide when burning wood.

An integral part of an autonomous heating system is the chimney. Proper design and correct installation of a pipe for removing combustion products will help avoid the unpleasant smell of carbon monoxide when burning wood.

The content of the article

What should a chimney be like for a solid fuel boiler?

The main purpose of the smoke exhaust pipe is to remove waste gases after burning wood in the firebox. The ability to remove combustion products is characterized by the natural draft that the chimney creates due to air rarefaction when the height changes from the point of intake of combustible gases to the level of release into the atmosphere. The change in atmospheric pressure between the bottom and top of the pipe is measured in Pascals. This characteristic depends on the height and diameter of the gas outlet channel.

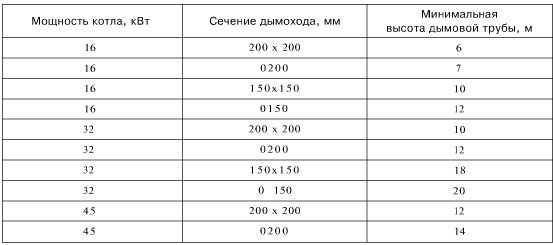

For uninterrupted operation of solid fuel equipment, boiler manufacturers indicate the vacuum value for the models they sell. Depending on the power of the heating unit, the requirements for the chimney change: the greater the performance, the higher the vacuum value. To save the consumer from complex calculations of the length and diameter of the chimney pipe, boiler manufacturers indicate the recommended diameter and height of the channel for removing combustion products.

ATTENTION! When making a heating boiler yourself, the size of the chimney is similar to that of industrial analogues in terms of power.

The main requirements for a smoke exhaust pipe are the correspondence of the length and cross-section of the channel to create the required draft. The cross-sectional shape also affects the quality of traction, but to a lesser extent. The channel material must withstand high temperatures and not be subject to corrosion. The condensate formed inside the pipe has destructive properties.

The main requirements for a smoke exhaust pipe are the correspondence of the length and cross-section of the channel to create the required draft. The cross-sectional shape also affects the quality of traction, but to a lesser extent. The channel material must withstand high temperatures and not be subject to corrosion. The condensate formed inside the pipe has destructive properties.

Is it possible to make a chimney for a solid fuel boiler with your own hands?

Installing a simple channel does not require high qualifications. It is important to observe correct assembly and monitor the tightness of the connections of the mounting structural elements.

A complex chimney, consisting of horizontal channels lined with brick, designed to use the heat of combustion products for heating purposes, will require the involvement of an experienced stove maker. Independent study of the features of laying brick chimneys will allow you to get the job done, but will take a lot of time.

A complex chimney, consisting of horizontal channels lined with brick, designed to use the heat of combustion products for heating purposes, will require the involvement of an experienced stove maker. Independent study of the features of laying brick chimneys will allow you to get the job done, but will take a lot of time.

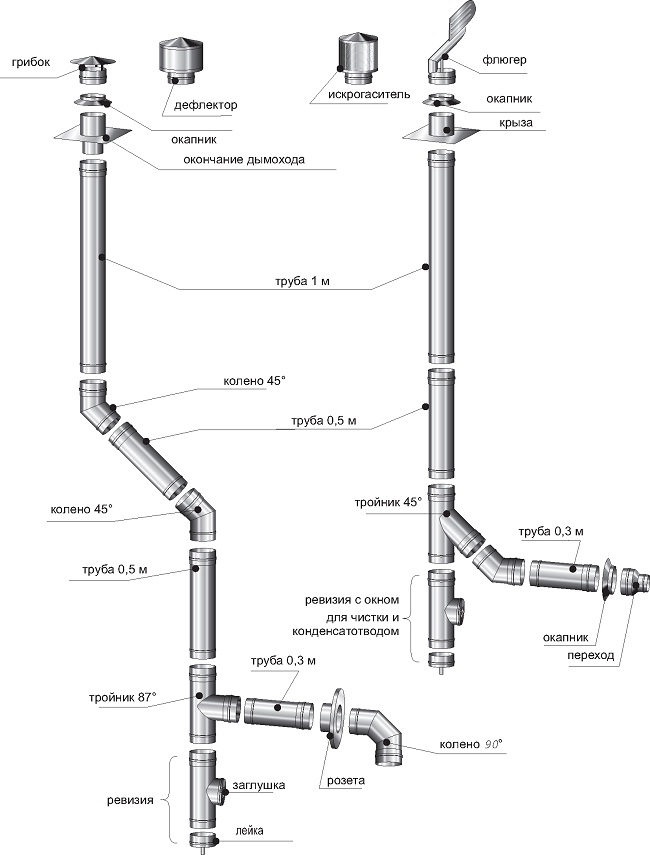

Installation of a smoke exhaust duct made of metal pipes will not take much time and will allow combustion products to be completely removed with the correct selection of diameter and height.Manufacturers of heating equipment offer a large selection of metal products for the removal of combustion products. They have different sizes and convenient fastening.

IMPORTANT! When installing connections, the upper element of the chimney is inserted into the lower one so that the condensate flows down the inner surface of the channel!

What material should the chimney be made of?

Modern smoke exhaust pipes are made from:

- asbestos;

- glass;

- ceramics;

- bricks;

- metal

Asbestos chimneys have long been used to remove combustion products. At the beginning of the 21st century, researchers identified the harmful effects of this material on human health when heated. Given their low cost, asbestos pipes are in demand to this day. They are connected to the boilers through metal adapters.

Asbestos chimneys have long been used to remove combustion products. At the beginning of the 21st century, researchers identified the harmful effects of this material on human health when heated. Given their low cost, asbestos pipes are in demand to this day. They are connected to the boilers through metal adapters.

Glass smoke exhaust ducts are very expensive. Ceramic pipes are difficult to install. Both of these materials are rarely used for exhaust gas removal, but due to the fact that the inner surface is very smooth, there are those who want to build such a chimney.

Glass smoke exhaust ducts are very expensive. Ceramic pipes are difficult to install. Both of these materials are rarely used for exhaust gas removal, but due to the fact that the inner surface is very smooth, there are those who want to build such a chimney.

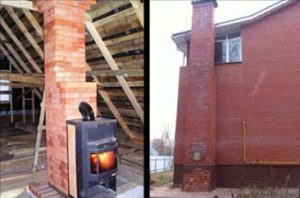

Brick chimneys are traditionally used in the construction of stoves. To connect the brick structure to the boiler, metal transitions and connecting elements are used.

The presence of condensate inside the chimney duct makes the use of steel pipes ineffective. They wear out quickly. A common material for smoke exhaust ducts is heat-resistant stainless steel. Systems made from this material are equipped with all kinds of adapters, turns and fasteners, which allow you to quickly and efficiently install pipes for the removal of combustion products.The smooth internal surface provides good traction and makes the system easy to maintain. The heat-resistant properties of the material allow it to withstand high temperatures when using coal.

The presence of condensate inside the chimney duct makes the use of steel pipes ineffective. They wear out quickly. A common material for smoke exhaust ducts is heat-resistant stainless steel. Systems made from this material are equipped with all kinds of adapters, turns and fasteners, which allow you to quickly and efficiently install pipes for the removal of combustion products.The smooth internal surface provides good traction and makes the system easy to maintain. The heat-resistant properties of the material allow it to withstand high temperatures when using coal.

What knowledge about a chimney is needed to make one with your own hands?

To independently carry out work on assembling a smoke exhaust duct, it is necessary to understand that an air flow must pass through the working hole, ensuring the required combustion mode of solid fuel equipment. This flow is measured in cubic meters. m/hour. The need to change the amount of hot air movement is determined by the thermal characteristics of the boiler.

The greater the boiler power, the greater the amount of air flow that must pass through the chimney. In other words, the draft is directly proportional to the power of the heating equipment. Usually, to determine the diameter and height of the smoke exhaust duct, they use special tables or select similar parameters recommended by boiler manufacturers.

REFERENCE! SNiPs provide for the calculation of the draft of heating equipment for exhaust gas removal. The calculation is due to a large number of initial data of the boiler, chimney materials and comes down to determining the vacuum expressed in Pascals. This calculation does not provide a clear definition of the pipe size.

What tools will you need?

To perform installation work on the installation of a chimney duct you will need:

- measuring devices;

- metalworking tools;

- drill, hammer drill;

- Bulgarian;

- rope;

- wooden bars.

IMPORTANT! When installing a smoke exhaust duct, the metal elements are connected using wooden spacers. It is prohibited to hit the end part of the pipes with a hammer.

How to make a chimney drawing

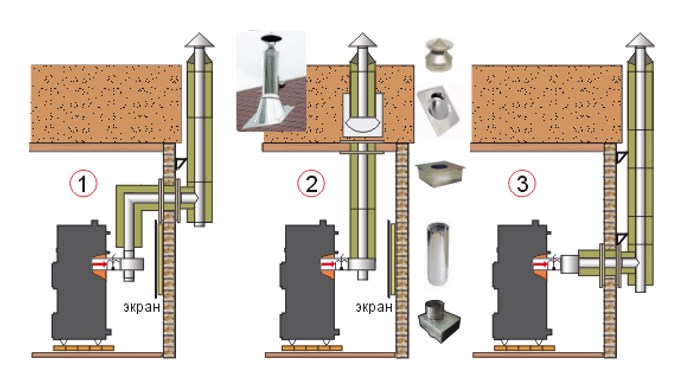

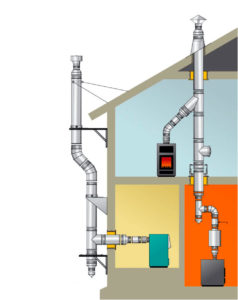

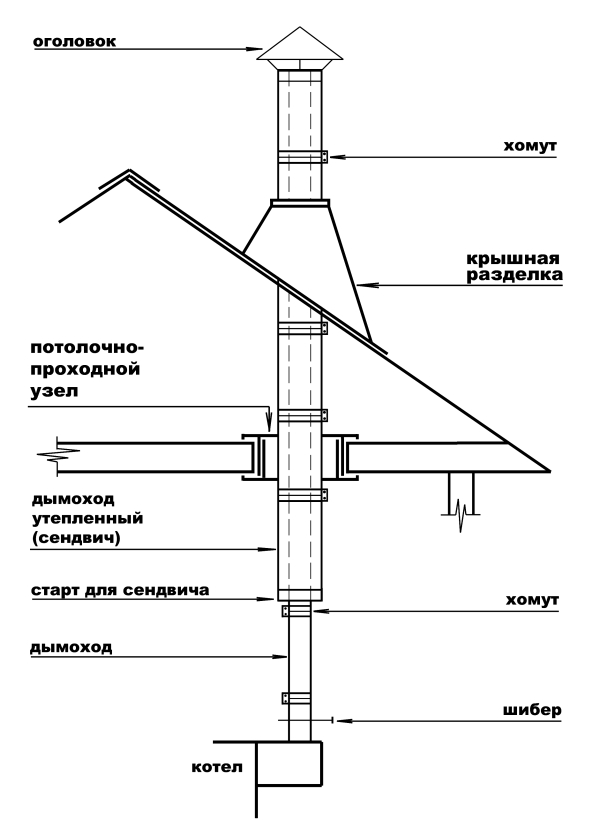

Before installing the smoke exhaust duct, it is necessary to make a sketch and make sure that the intended design is selected correctly. The drawing shows a side view of the house and outlines the gas exhaust pipe.

When the distance from the ridge to the pipe is less than 1.5 m, the chimney is designed 50 cm above the top line of the roof. When the position of the smoke exhaust duct changes to 3 m, the upper part is installed at the level of the ridge. And at a greater distance, draw a tangent line along the top point of the pipe and roof. The slope of the drawn straight line should have a deviation from the horizon of no more than 10 degrees.

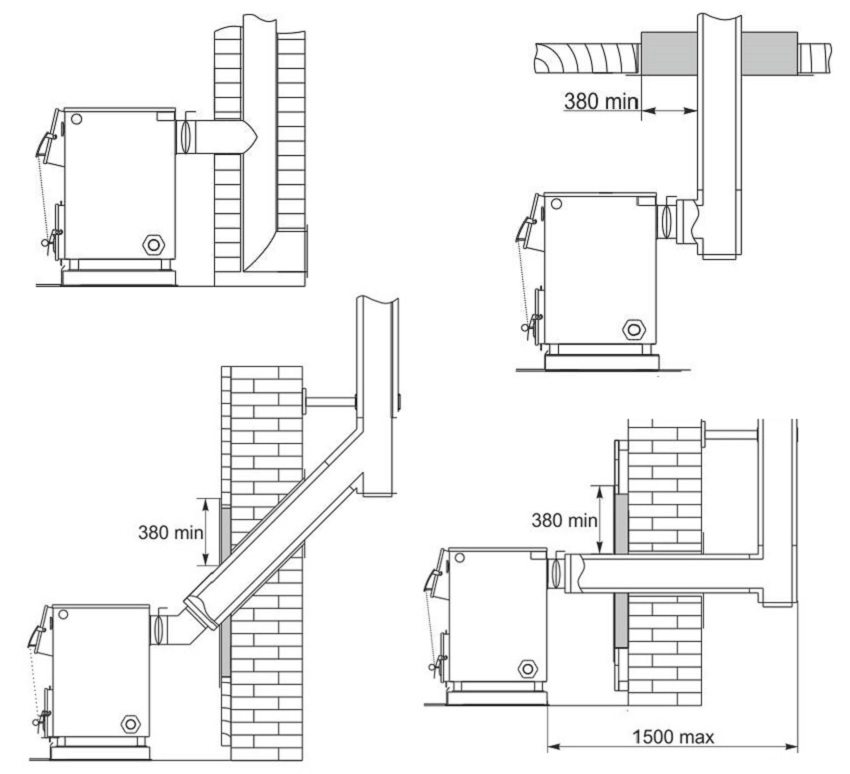

In addition to a sketch of the house with a depiction of a pipe for removing exhaust gases, a drawing of the passage of the channel through the roof, the ceiling of the floors and the connection to the heating equipment is made. It may be the same or a different drawing. The connection of the boiler to the chimney is made at a right or obtuse angle in the direction of movement of the combustion products.

ATTENTION! Connecting pipes through an acute angle will disrupt natural draft and will not allow the smoke exhaust system to function normally. There will always be a burning smell in the house, and to get rid of it, the connection will have to be redone.

The drawing indicates the height and diameter of the exhaust gas channel.

How to calculate the chimney height for a solid fuel boiler

When calculating the value of the pipe height (Wtr), a special formula is used that takes into account:

- boiler power, say, Mk = 30 kW;

- required static draft, St = 23 Pa (for domestic boilers with a power of 25-30 kW);

- exhaust gas temperature, Тg=530 K (for firewood);

- ambient temperature, To=290 K (for middle latitudes).

The formula uses calculated coefficients 3459 and 1.1, which are constant values.

Vtr = St*Tg*To/3459*(Tg-1.1*To) = 23*530*290/3459*(530-1.1*290) = 3535100/3459*211 = 3535100/729849 = 4, 84 m

The obtained value is calculated for the accepted values of static thrust and combustion temperature. All calculations are made in Kelvin.

ATTENTION! To calculate the pipe parameters of a coal-fired boiler, the temperature of the combustion products is taken to be 200-400 degrees higher (depending on the type of solid fuel).

Chimney diameter for solid fuel boiler

The diameter of the channels for exhaust gas removal is made no less than the size of the outlet pipe of the heating equipment. It is impossible to reduce or narrow the cross-section of pipes - this impairs draft and interferes with the combustion process. An increase in the passage size is acceptable, but with a small jump.

ATTENTION! When making a boiler yourself, the diameter of the pipe is made the same size as that of analogues from industrial manufacturers of heating equipment. The model of mass-produced units is selected according to power or similar size of the firebox and volume of the water jacket.

How to make a chimney for a solid fuel boiler yourself: step-by-step instructions

Having the skills to work with plumbing and power tools will allow you to easily install chimney pipes with your own hands. Let's consider the possibility of self-assembling a metal channel for removing combustion products.

Having the skills to work with plumbing and power tools will allow you to easily install chimney pipes with your own hands. Let's consider the possibility of self-assembling a metal channel for removing combustion products.

- First of all, prepare all the constituent elements: bends, transitions, extensions and fasteners.

- Cut a hole in the roof and ceiling using a grinder and install a fastening clamp at the bottom of the roof covering and under the ceiling.

- The upper chimney pipe is fixed in the designed location, having previously installed a protective umbrella and a water deflector on it.

- Assemble the required number of meter-long (standard length for individual elements) pipes from the roof surface to the ceiling. Connected to the top element and secured under the ceiling. When installing near a wall, each meter section of the chimney is secured with a clamp.

- After this, pipes are assembled with a tee, which is designed to connect to the boiler or extension cord. Then the upper part is inserted into the connecting socket of the chimney duct under the ceiling and the horizontal socket of the boiler is joined to the assembled structure. Using wooden spacers, tightly knock down the joints of the smoke exhaust system. After making sure that the individual elements are firmly seated, the assembled structure is secured with clamps.

ATTENTION! Before drilling holes for installing clamps, it is necessary to pre-assemble the chimney elements to ensure accurate drilling of holes.

The distance between horizontal sections should not be more than 1 meter. If the length of the connected pipe sections is longer, then inclined installation elements are used.

- The cavities around the pipes, at the intersections with the roof and ceiling, are filled with foam for tightness.

IMPORTANT! Only heat-resistant polyurethane foam is used. The temperature of the gases inside the channels reaches 400 degrees.

- After completing the work, check the tightness of the ceiling, and especially the roof. Water should not flow under the water deflector or seep through the pores of the mounting hole.

The chimney is ready for use.We can say with confidence that the use of heat-resistant stainless steel is the optimal solution for the construction of a chimney system. Compliance with all requirements, including fireproof ones, will allow the assembled structure to be used for a long period of time.