What should be the pressure in the heating boiler?

Water heating systems operate with or without pressure inside the lines. This is due to the design features of the heating complex as a whole and its individual elements. Pressure makes it possible to increase the efficiency of equipment use and requires installation of lines, which are called closed circuits, by qualified specialists. The operation of open heating systems (by gravity) is gradually becoming a thing of the past, but due to its simplicity, it still finds application in everyday life.

Water heating systems operate with or without pressure inside the lines. This is due to the design features of the heating complex as a whole and its individual elements. Pressure makes it possible to increase the efficiency of equipment use and requires installation of lines, which are called closed circuits, by qualified specialists. The operation of open heating systems (by gravity) is gradually becoming a thing of the past, but due to its simplicity, it still finds application in everyday life.

The content of the article

What pressure in the boiler is considered normal?

The value of this indicator in a heating system depends on the purpose of the lines and the heat sources used. For example, for a high-rise building, a pressure of 7–11 atmospheres (atm) is considered normal, and for an autonomous main line of a two-story private cottage, depending on the design of the boiler heat exchanger, a value of up to 3 atm will be acceptable.

The value depends on the equipment and the strength of the coil in which the coolant is heated. Modern household gas units are equipped with durable heat exchangers that can withstand 3 atmospheres. Manufacturers of solid fuel equipment recommend not exceeding 2 atm.

The given values indicate the maximum value for which the boiler is designed. There is no need to operate it in this mode at all. Moreover, when heated, pressure increases. An average value will be sufficient, which will ensure the required performance of the unit and radiators.

To determine the operational value, take into account the recommendations of the manufacturers of the boiler used and the installed heating devices. All of them come down to indicators from 0.5 to 1.5 atm. The pressure value of the autonomous system, which is within these limits, is considered normal!

ATTENTION! Some users of modern systems claim that the higher the pressure, the greater the efficiency of thermal equipment. Research shows that the differences between operation at 1 and 2 atm are insignificant when it comes to autonomous systems. At the same time, the wear of the connecting elements of the line increases by an order of magnitude!

Pressure fluctuations that occur when operating in heating mode will have less impact on components and devices at a lower value. Operation at 2 or more atmospheres will require additional load, as well as periodic operation of a closed expansion tank and safety valve.

Reasons for deviation from the norm

The need for heating occurs throughout the entire cold period of the year, which means 6 months of continuous heat supply (for mid-latitudes). During such a period of time, the system must uninterruptedly produce the required thermal power, and the pressure in the line must have a constant value. In practice it doesn't always happen this way. The influence of external and other factors causes interruptions in the operation of heating equipment. Let's consider the reasons that affect the parameters of autonomous systems.

Why do pressure readings drop?

The first and main reason for a decrease in the operating parameter is a coolant leak at the junctions of pipelines with heating equipment. To temporarily eliminate this deficiency, use a boost valve. If not, refill the line with coolant as the pressure drops, from the water supply network or well. Such measures will temporarily normalize the pressure force.

To completely eliminate the deficiency, you must:

- detect a leak;

- turn off the heat source;

- drain the coolant in the main section, having previously shut off the flow of water;

- repair the required unit;

- pump water, turn on the boiler.

IMPORTANT! If it is not possible to drain the coolant in a separate area, in autonomous systems the line is emptied, and after the malfunction is eliminated, it is refilled!

Leak detection is possible if there is a wet spot or droplets on the pipe connections. In cases where it is not possible to see a leak, first increase the pressure to 3 atmospheres and turn on the circulation pump. If this does not help, then drain the water and pump in air. The location of the air leak is determined by sound, and verified using soapy water, which will indicate the exact location of the defect.

The reason for the decrease in pressure may be wear and tear of heating equipment, the appearance of scale in the heat exchanger and system pipes. Another little-known reason for a decrease in operating parameters is a decrease in temperature. When an unheated house cools down in the cold season, and the coolant cools accordingly, the parameter value drops by 0.5 atm or more.In such a situation, maintain the lower limit of the value at 0.9-1.0 atm and prevent the coolant from freezing during periodic heating operation.

Why does blood pressure increase sharply?

A malfunction of the automation system that ensures automatic filling of the main line is often the reason for a rapid change in parameters. In addition, slowing down the circulation of coolant through the pipes leads to overheating, and accordingly to an increase in pressure. The reason may be air locks, as well as the presence of dirt in the filter or other system components.

To identify the reasons for the growth of the controlled parameter, all emerging factors are compared, and then conclusions are drawn. A simple method of eliminating a sudden increase in pressure is to bleed off excess coolant, forcefully turn on the pump, then pump up water, if necessary, to the set value. Repeating the procedure with a smaller amplitude of jumps and gradual leveling of the controlled parameter indicates the elimination of the air lock.

The inability to eliminate the cause using this method indicates the presence of “impenetrable” dirt that interferes with the normal operation of the boiler. To eliminate this reason, first clean the filter, and if that doesn’t help, clean the heat exchanger. Cleaning methods are used both mechanical and hydraulic. It is important not to damage the internal cavity and connecting pipes.

REFERENCE! When operating solid fuel boilers, especially during ignition, the pressure surge can change the value by 1-1.2 atm! It is important to compare the change in the controlled parameter with the increase in temperature. The direct dependence of the compared values indicates the need to slow down the ignition of the unit.

Monitoring and eliminating pressure surges in the heating system

To obtain objective information about the operation of the entire pipeline, it is equipped with several pressure gauges. The number of thermometers is always not enough to objectively assess the performance of individual sections. By comparing data from measuring instruments in different modes, the user can independently identify the location of unstable heat transfer and possible malfunction.

Reliable operation of the entire heating system is achieved by installing:

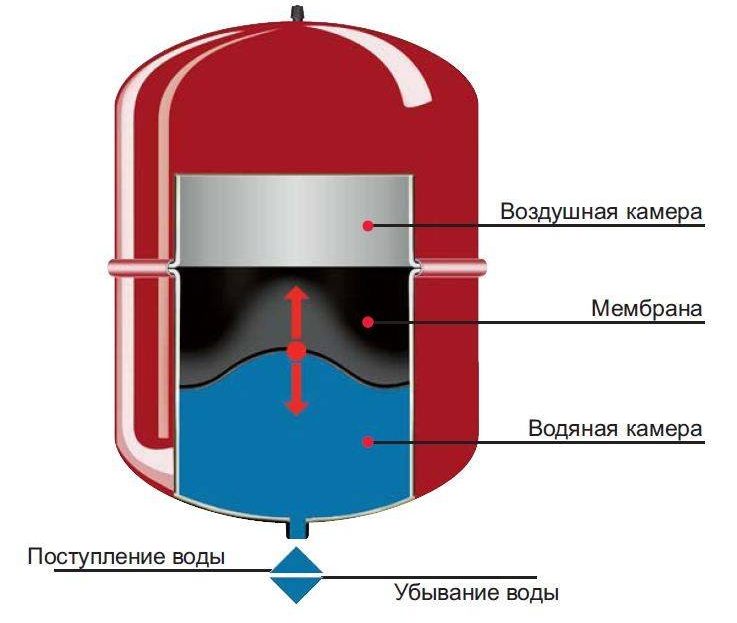

- a membrane expansion tank, which, when the pressure increases above 2 atm, compensates for its further increase;

- a safety group consisting of an automatic air vent, a pressure gauge and a valve set to a certain value, after which it opens and releases excess pressure.

The expansion tank is installed on the “return”, and the air vent with other devices is installed at the top point of the “supply” line. The presence of these attributes eliminates the possibility of pipeline ruptures and damage to the boiler heat exchanger.

ATTENTION! When installing an explosion-proof valve, its performance is checked by artificially creating high pressure!

After familiarizing yourself with the operating pressure parameters of the system, each autonomous heating user can independently diagnose the cause of the malfunction and, if desired, eliminate it.

Well, why are YOU the author writing like that about the air test?If no damage is detected during hydrotesting, then the proposal to hear the hiss of air and wash it again does not stand up to criticism?! Water is practically not compressible, unlike air, and everywhere GI is carried out with water, in exceptional cases when it is impossible to GI with water (street, frosty water. If the water freezes, air is used). Well, washing is the lot of the gas service.