How to install a draft regulator on a boiler

A heterogeneous and complex concept that includes several factors is traction force. This parameter must be at the highest level in order for the device to operate stably. The way energy is generated and fuel is burned is influenced by the standard deviation of traction force indicators. Most often, owners of solid fuel boilers encounter this problem if there are irregularities in installation work. Prudent people purchase a draft regulator along with the equipment in order not to encounter such a problem.

A heterogeneous and complex concept that includes several factors is traction force. This parameter must be at the highest level in order for the device to operate stably. The way energy is generated and fuel is burned is influenced by the standard deviation of traction force indicators. Most often, owners of solid fuel boilers encounter this problem if there are irregularities in installation work. Prudent people purchase a draft regulator along with the equipment in order not to encounter such a problem.

The content of the article

How to properly install a draft regulator on a boiler

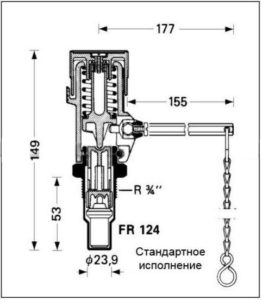

The thermostat is one of the most important elements in the draft regulator. It is located inside a cylindrical body, it has a mechanical connection with a lever and a chain. The thermostat looks like a sealed flask containing a heat-sensitive liquid that expands when heated. The element is located directly on the side that contacts the equipment.

What you need for installation

To install a draft regulator in a solid fuel boiler you will need:

- homemade or purchased draft regulator;

- solid fuel equipment;

- tools;

- self-tapping screws

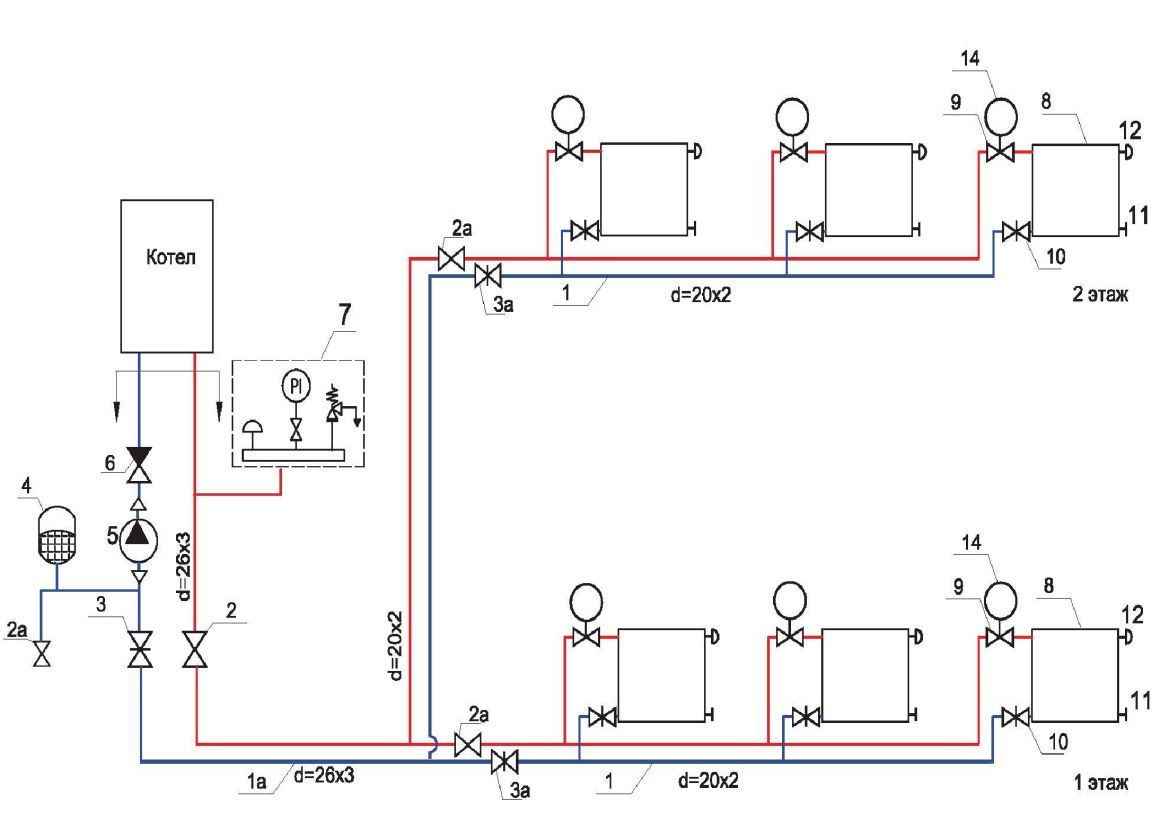

Regulator installation diagram

The regulator is connected to the fitting in the boiler with internal and external threads. A special sealant is used to seal the threads. Depending on where the tip of the rod is directed, the device is installed.

The transport pipe made of plastic is removed from the equipment. In its place, a hexagonal lever is installed on the front side. There shouldn't be a hole in it. When tightening the screw when fixing the rod, it is necessary to ensure that its shoulder is close to the horizontal hexagon, and the opposite end should be located above the boiler door chain. A large hook is inserted into the hole in the regulator lever, which is fixedly connected to the chain. The free hook should connect the remaining end of the chain. After this, it is checked (by turning the button) whether the lever and chain move freely. If you install the regulator horizontally, you must align it with the white scale. Use the red scale to guide you when installing the device in other positions.

Important! The device must be installed exactly as written in the instructions; there should be no middle solution under any circumstances.

How to configure the regulator after installation

In order to properly configure the device after installation, you must strictly follow the step-by-step instructions:

- Open the boiler door and do not close it with a chain. This is done in order to let air in.

- The locking screw on the adjustment handle is loosened.

- The handle is inserted at the required temperature, for example, 650WITH.

- The thermometer on the solid fuel boiler is monitored after the mark reaches 650C it is necessary to connect the chain wire to the damper.The main thing is not to close the damper completely. It should always be slightly open a couple of millimeters.

- The fixing screw is tightened.

Important! The chain has free play, but it should not exceed 1 mm.

After this, the device is checked in all modes, even at the maximum. The main thing to remember is that time must pass between checks, since the solid fuel boiler heats up and does not always have time to cool down. To obtain the most effective result, you need to wait for some time so that the temperature conditions do not go astray.

Coal or firewood fades gradually, so solid fuel thermogenerators need a little more time to cool down than other similar equipment.

How to choose the right draft regulator

The modern market offers a large number of models of solid fuel boilers. But not all of them are equipped with automation. In such models, the sleeve is mounted directly into the heat exchanger. Such boilers must be equipped with a draft regulator.

In order to choose the right mechanical traction device, you must adhere to the following instructions:

- To successfully lift the sash, it is necessary that its weight and the power of the thermostat match.

- Temperature range should be between 60-800WITH.

- The lever must have a rotation angle such that it is enough to completely close and open the sash.

- The threads in the boiler and the draft regulator must match each other in order to be connected.

Attention! The sleeve on the equipment may be located on the top or side, so it is very important to select a regulator with the correct operating mode. Models have been developed in which work can be done in any position.

Equipment functions

In a solid fuel boiler, temperature plays a very important role, so a thermostat is needed. This equipment is equipped with a water jacket. To prevent the water in the unit from boiling, it is necessary to install an automatic or mechanical draft regulator.

If water boils in such equipment, it may explode as pressure increases. When installing a mechanical regulator, you will have to constantly monitor it. If you install automatic equipment on a solid fuel boiler, then human intervention will not be required.