How to properly heat a solid fuel boiler with wood

It would seem, what does it mean to “properly” heat a boiler with wood? What's so complicated about it, throw your firewood into the firebox before the coals cool down, and the whole process. It turns out that it's not that simple. How efficiently a boiler operates does not primarily depend on its design. First of all, the result of its work, as well as its efficiency, depends on the quality of the fuel used. Not only the type of wood is important, but also whether it is dry or damp, and the condition of the valves and chokes. The nuances of operating solid fuel boilers will be discussed in the article.

It would seem, what does it mean to “properly” heat a boiler with wood? What's so complicated about it, throw your firewood into the firebox before the coals cool down, and the whole process. It turns out that it's not that simple. How efficiently a boiler operates does not primarily depend on its design. First of all, the result of its work, as well as its efficiency, depends on the quality of the fuel used. Not only the type of wood is important, but also whether it is dry or damp, and the condition of the valves and chokes. The nuances of operating solid fuel boilers will be discussed in the article.

The content of the article

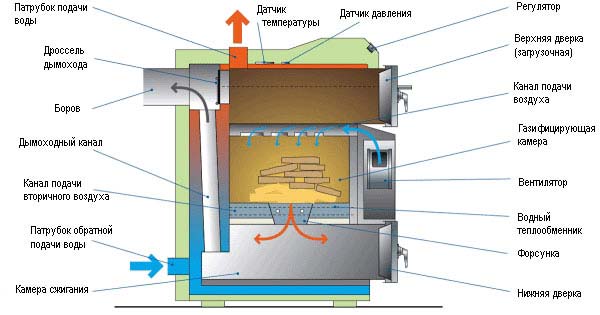

How does a solid fuel wood boiler work?

The boiler works as follows:

- As a result of the combustion of wood in the firebox, a certain amount of heat is released, different for different species.

- The heat is used to heat the water tank located above the firebox.

- Water circulates through a pipeline from the tank to the heating radiators and back in a closed circuit. Circulation can be either natural (when the pipes are located at a slight slope) or forced, through a circulation pump.

- Combustion products are discharged through a chimney to the street. In order for the draft to be normal, the vertical part of the chimney is made three or more meters high.

- The combustion intensity is regulated using the firebox and chimney dampers.

Important!

The heating unit is equipped with a safety system for emergency pressure relief in case of overheating. If this is not done, the boiler becomes dangerous to operate.

How to heat a solid fuel boiler with wood

Before you start heating, you need to properly make the kindling, but if you ignore it, smoke may begin to seep into your home. Different types of wood are better suited for different stages of the process; the size of the wood also matters in this case.

Which firewood to choose

It is recommended to burn with well-dried wood, and its varieties are worth dwelling on separately.

- Birch gives a lot of heat, burns for a long time, but during the combustion process it leaves a large amount of tar on the walls of the chimney.

- Alder produces one and a half times less heat than birch, but leaves virtually no soot. Well suited for kindling as it ignites easily.

- Aspen also does not produce soot and produces little heat; it is also advisable to use it as kindling.

- Pine burns hot, but contains a lot of resin and produces a large amount of soot. Spruce firewood burns hotter than pine firewood, while producing less soot.

- Poplar, releasing a lot of heat, burns out very quickly.

- Apple and pear produce a lot of heat, good coals, but knotty and difficult to prick.

- Oak, ash and beech are dense and hard, and are difficult to chip. When burned, they release a lot of heat and produce little soot. Rarely found on sale.

Taking into account the above properties, firewood is selected both for kindling and for directly heating the boiler.

Correct sequence of actions

The process begins with cleaning the ash pan and subsequent kindling. This stage can take about an hour.The purpose of kindling is to warm up the firebox and chimney to create sufficient draft. The complexity and duration of the process is determined by the shape of the chimney and the presence of horizontal sections in it.

The process begins with cleaning the ash pan and subsequent kindling. This stage can take about an hour.The purpose of kindling is to warm up the firebox and chimney to create sufficient draft. The complexity and duration of the process is determined by the shape of the chimney and the presence of horizontal sections in it.

Crumpled paper, bark, and small wood chips are used as kindling. Then thin logs are placed. After they are ignited, add wood little by little until the firebox is half loaded. The vent and chimney dampers are opened wide during the kindling process to ensure good air flow. It is also recommended to open the windows in the room to increase the flow of fresh air. After the flame burns well, close the dampers halfway.

Crumpled paper, bark, and small wood chips are used as kindling. Then thin logs are placed. After they are ignited, add wood little by little until the firebox is half loaded. The vent and chimney dampers are opened wide during the kindling process to ensure good air flow. It is also recommended to open the windows in the room to increase the flow of fresh air. After the flame burns well, close the dampers halfway.

After sufficient heating, full fillings begin, and the rate of their burning is determined by the type of wood and the position of the dampers.

On a note!

To automate the adjustment process, thermostatic draft regulators and fans with controllers equipped with a temperature sensor are used. These devices can significantly simplify temperature control and increase boiler efficiency.

Features of working with a wood-burning boiler

Unlike devices running on liquid fuel or gas, wood-burning boilers do not release heat into the room evenly, this is due to the peculiarity of the combustion process. In the middle of the process, significantly more heat is released than at the beginning and end. The dampers on the vent and on the chimney help more or less equalize the amount of heat produced.

Unlike devices running on liquid fuel or gas, wood-burning boilers do not release heat into the room evenly, this is due to the peculiarity of the combustion process. In the middle of the process, significantly more heat is released than at the beginning and end. The dampers on the vent and on the chimney help more or less equalize the amount of heat produced.