DIY gas boiler

When cold weather sets in, we often think about how to heat our home before the heating season begins or for the entire period. After all, the cost of purchasing and installing a boiler is very high, so you can make a gas boiler yourself.

When cold weather sets in, we often think about how to heat our home before the heating season begins or for the entire period. After all, the cost of purchasing and installing a boiler is very high, so you can make a gas boiler yourself.

The content of the article

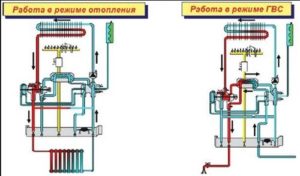

The principle of operation of a gas boiler

A gas boiler consists of the following components:

- gas burner;

- heat exchanger;

- pump;

- expansion tank;

- automation;

- fan;

- security systems;

- thermometer;

- pressure gauge;

- gas valve;

- air vent.

When this device is connected to the network, the gas burner lights up. It heats the heat exchanger with the contents to a certain temperature. Next, the pump starts working, which creates pressure. Under its influence, the coolant constantly circulates through the pipes, while releasing heat into the room using a radiator.

DIY boiler

To assemble a boiler with your own hands, you need to understand that you are taking on great responsibility as this process is unsafe. First, you will need a diagram in which each stage will be described in detail, then you need to calculate and prepare all the necessary parts for manufacturing.

IMPORTANT! The gas service does not approve of the installation of homemade equipment as it is contrary to the law.

From the geyser

A gas boiler can be made from a gas water heater. With its help you can heat a small room, such as a bathhouse. The column has high productivity, so it consumes a lot of natural gas. For this equipment, you will need to reduce the consumption of this substance by installing 2 gas burners made in China, making a hole in the nozzles measuring 1 mm. Instead of an expansion tank, a plastic tank or gas cylinder is often used. It is installed on the supply line so that no vacuum is created during pump operation. The pump is used new or taken from an old washing machine, the control unit is installed without a timer.

A gas boiler can be made from a gas water heater. With its help you can heat a small room, such as a bathhouse. The column has high productivity, so it consumes a lot of natural gas. For this equipment, you will need to reduce the consumption of this substance by installing 2 gas burners made in China, making a hole in the nozzles measuring 1 mm. Instead of an expansion tank, a plastic tank or gas cylinder is often used. It is installed on the supply line so that no vacuum is created during pump operation. The pump is used new or taken from an old washing machine, the control unit is installed without a timer.

From a gas stove

A metal tank filled with water is installed on the heating burner, which is connected to a pipeline made of plastic through the top. A pump is connected to the container below, with the help of which water is supplied to the batteries.

To make the device safe, an expansion tank is installed; a small gas cylinder is suitable for this. A safety valve is also installed to prevent all sorts of obstacles to the supply of electricity to it.

Such heating equipment will not have enough power to heat an apartment or house during frosts, but it is well suited for heating in the autumn or spring.

From a cylinder

To assemble this equipment from a cylinder, you should prepare the following tools:

- gas cylinder, 50 liters;

- Metal sheet;

- electrodes;

- welding machine;

- angle grinder.

To begin with, the top of the cylinder is cut off; in the future it will be used as a closing part with handles.Then a piston with a lower nozzle is placed in the middle of the container, which includes an empty pipe, with its help air from the atmosphere enters the middle for the combustion process. A “pancake” is welded to the bottom of the piston, the size of which is smaller than the cylinder itself. Blades in the form of an arc are attached to it to form a circular flow movement over the smoldering combustible substance. This element will not allow open fire to occur.

ATTENTION! This equipment will ensure that the fire burns slowly, while the gas moves upward and burns.

For the chimney, a hole is cut from the side of the cylinder, to which a drain pipe is welded and brought to the outside. This pipe is made of two parts, the diameters of which are 0.15 m and 0.2 m. Pipes of different diameters are used for longer combustion.

It will also be necessary to make a water jacket for heating.

IMPORTANT! It would be more economical to make a container with coolant around the chimney.

Heating pipes are connected to the jacket, and an expansion tank is installed on the upper supply pipe. Next, a pump is installed to ensure natural circulation.

From a solid fuel boiler

This type of boiler can be converted into a gas one, but it will need to be radically altered. This will require welding one-inch pipes made of metal over the burner of the equipment, which will allow thermal energy to circulate in the pipes.

This type of boiler can be converted into a gas one, but it will need to be radically altered. This will require welding one-inch pipes made of metal over the burner of the equipment, which will allow thermal energy to circulate in the pipes.

IMPORTANT! Having converted a solid fuel boiler, you will not be able to use it in the previous mode.

First, the existing boiler is disassembled. Next, pipes are installed, which are placed:

- at a height of 3 cm from the burner;

- at an angle so that the liquid in the pipes does not stagnate or boil;

- in three rows at a distance of about 15–20 mm from each other.

From the outside, an angle grinder is used to cut a hole in the water jacket of the boiler, slightly larger than necessary. Using a crown with Pobedite bits, holes are drilled in the metal for pipes.

IMPORTANT! To install pipes at an angle, it is necessary to select the diameter of the crown so that it is larger than the diameter of the pipes.

When drilling, it is recommended to periodically water the hole with a soap solution so that the heating tips do not break off. The pipes are welded with a gas torch.

Then the water jacket is sealed. In the middle you need to weld a pin from the fittings, which will prevent the boiler from swelling. At the end of the process, a hole is welded around the entire edge. Before installing the boiler, liquid is poured into it and checked for leaks. When identified, a hole is made again and the leak site is welded.