DIY electric boiler

Electric heating systems are extremely simple equipment that allow you to create optimal temperature conditions in the house, even when it is a severe and snowy winter outside. Such devices have impressive efficiency and operate stably for a long time. But few people know that to heat an apartment or house it is not at all necessary to purchase expensive equipment, and you can make an electric boiler with your own hands. It is this issue that we decided to pay detailed attention to in today’s article.

Electric heating systems are extremely simple equipment that allow you to create optimal temperature conditions in the house, even when it is a severe and snowy winter outside. Such devices have impressive efficiency and operate stably for a long time. But few people know that to heat an apartment or house it is not at all necessary to purchase expensive equipment, and you can make an electric boiler with your own hands. It is this issue that we decided to pay detailed attention to in today’s article.

The content of the article

Choosing the type of electric boiler

At the moment, there are three types of boilers, which differ in heating method:

- induction;

- electrode;

- models with heating element.

Now let's talk about each type.

Boiler with heating element. This is a classic that will probably never go out of style. The heating element in this device is the heating element, which transfers heat to the liquid, which, in turn, transfers it to the radiators.

Attention! Using water of high hardness can lead to the formation of deposits on the heating element, which will reduce the performance of the equipment.To prevent this, it is necessary to regularly treat the heating element with substances intended for this purpose.

Advantages of boilers with heating elements:

- extensive functionality;

- withstand a variety of damage;

- the heater shell is not connected to voltage;

- the system works perfectly with insufficient contact with the coolant.

Induction models. These devices appeared on the market relatively recently, but have already become very popular among consumers. They work quite simply: the equipment creates electromagnetic waves that interact with metal. The rest of the material is not affected, and therefore it is unlikely that you will get a burn when coming into contact with the equipment.

Induction models. These devices appeared on the market relatively recently, but have already become very popular among consumers. They work quite simply: the equipment creates electromagnetic waves that interact with metal. The rest of the material is not affected, and therefore it is unlikely that you will get a burn when coming into contact with the equipment.

The boiler includes a radiator and a pipeline with circulating liquid. She receives the radiation. The pipeline boasts impressive dimensions, and even if plaque forms on its walls, the performance indicator will not decrease.

The advantages of the models include:

- safety and reliable operation;

- excellent efficiency;

- rapid achievement of optimal temperatures;

- simple operation.

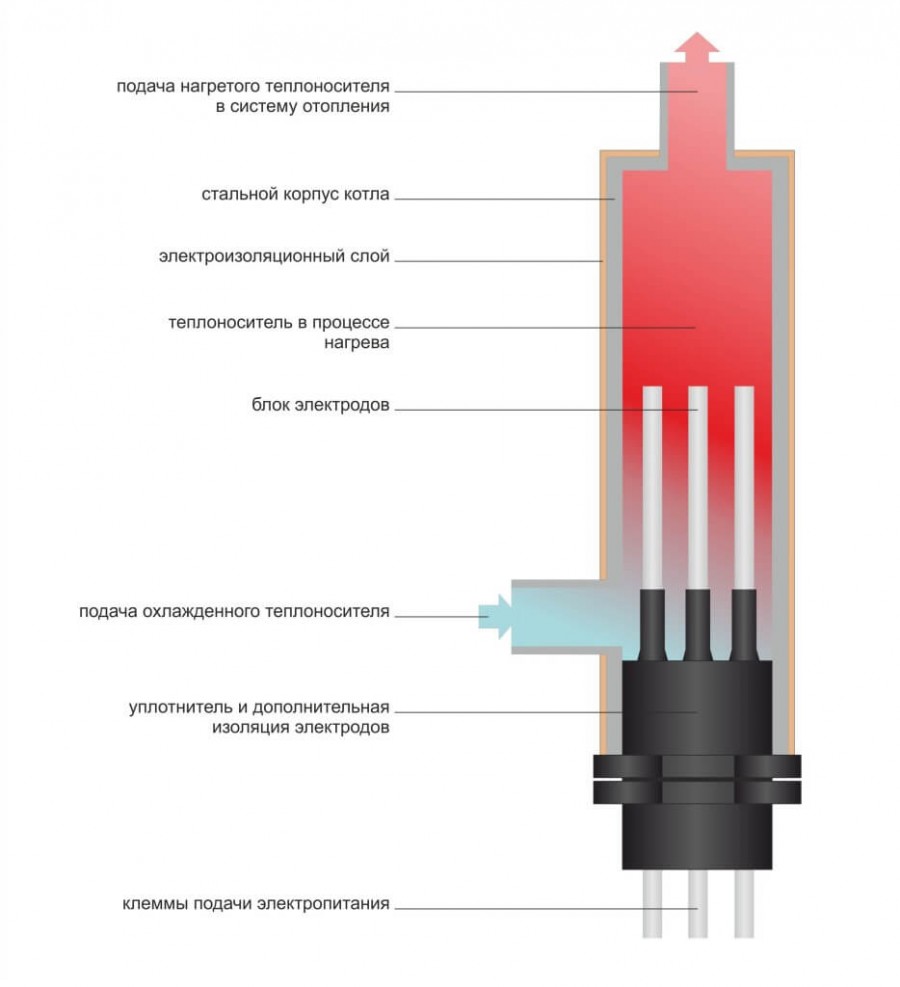

Electrode units. These devices are already in contact with the coolant fluid. The idea is that the device has a converter that influences the ions in the water. And, as a result, they begin to move chaotically and come into contact with other particles, releasing heat.

The main advantage of such models can be called complete immunity to circuit damage. When the ion chamber is left without coolant, it simply stops working. And this makes the operation of the boiler as safe as possible and helps prevent the formation of plaque.

How to make an electric heating boiler with your own hands

Electrical equipment does not include a mechanical component, which is why self-production can be called an extremely simple procedure. In addition, this factor eliminates the occurrence of a number of malfunctions that require expensive repairs.

Electrical equipment does not include a mechanical component, which is why self-production can be called an extremely simple procedure. In addition, this factor eliminates the occurrence of a number of malfunctions that require expensive repairs.

The design of such models implies the presence of temperature regulation. In view of the above, the system will be able to react in time to temperature changes that have occurred, and the boiler will either increase power or, on the contrary, reduce the temperature.

The boiler is powered from a regular outlet with a voltage of 220 V, and the average weight is 22 kg. Such a device can heat air up to 400 cubic meters.

Required Tools

To work you will need to prepare:

- grinder;

- welding equipment;

- grinding machine;

- multimeter

What materials will you need?

To work you need to take:

- sheet steel with a minimum thickness of 2 mm;

- adapters through which the device will be connected to the heating system;

- Heating elements (we buy 2 pieces in the store);

- steel pipe (the best option would be a pipe with a length of 50 to 60 cm and a diameter of 15.9 cm).

Making a homemade electric boiler

To make a good cauldron, follow these instructions:

- First, we prepare the pipes for connection to the heating system. We make them from pipes. A total of three pieces are needed - one with a diameter of 3 inches, and two of 1.25.

- Upon completion of the indicated step, we begin to manufacture the tank from stainless steel sheets. Next, we cut holes in it and weld the finished pipes. Afterwards, two circles are cut out of stainless steel, with a diameter larger than that of the pipe.This way you can weld them to the maximum quality.

- We weld the remaining pipe at the top, to which the heating element will be connected in the future. When the procedure is completed, we prepare the area for attaching the first heating element. For these purposes, 2 holes are made in the bottom of the container, and then they are polished and the part is placed in them.

- Now you can connect the equipment to the heating system and start it up.

Electric boiler diagram with heating element

Based on the information above, we can come to the conclusion that the boiler circuit includes:

- frame;

- a heating element;

- water inlet and outlet pipes;

- casing;

- mounting brackets.

How to connect a homemade electric boiler 220V

Before starting, you will need to once again inspect all connections, as well as wiring for damage.

Before starting, you will need to once again inspect all connections, as well as wiring for damage.

Important! It will be necessary to clean the structure from any contaminants, if any remain after assembling the boiler.

In addition, it is recommended to avoid voltage surges during the first start-up, which is why you need to install a protective exclusion device. After this, you can fill the system with water, connect it to the electrical network, and wait until it warms up to the desired temperature!