What is a boiler safety group

The piping complex for heating installations includes various elements, each of which is designed to implement a specific task. The so-called safety group is designed to prevent accidents when various emergency situations occur during boiler operation. What is its device and what is its operating principle?

The piping complex for heating installations includes various elements, each of which is designed to implement a specific task. The so-called safety group is designed to prevent accidents when various emergency situations occur during boiler operation. What is its device and what is its operating principle?

The content of the article

Design and principle of operation of a security group

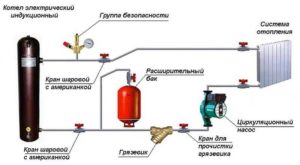

The heating boiler safety system group refers to devices responsible for the trouble-free provision of thermal energy to the consumer. The equipment set includes:

The heating boiler safety system group refers to devices responsible for the trouble-free provision of thermal energy to the consumer. The equipment set includes:

- device for automatic air exhaust;

- relief valve, safety valve;

- pressure gauge

Pressure control modules in the coolant system are installed in a metal housing equipped with threaded connectors. If the control equipment is installed in a cold room, then the choice should be a thermally insulated housing.

Air vent

According to the technical parameters of the heating boiler, a device for bleeding air, or a Mayevsky valve, is installed above the heater body to remove air released when heating the working environment of the system. Oxygen bubbles can also penetrate the line for a number of reasons:

- initial filling of the system with the working environment;

- replenishment of the pipeline with fresh coolant;

- defects in sealing gaskets;

- pipeline clogging with rust particles;

- poor-quality installation of the pipeline and equipment.

During the heating process, the working medium expands, releasing oxygen molecules that form an air plug, affecting the intensity of circulation of the working medium in the line. An automatic pressure relief device, the operating parameters of which can be adjusted without operator intervention, will help prevent pipe damage.

The process of adjusting pressure in the heating system is controlled by a float, rocker arm, and needle valve. The resulting air plug puts pressure on the float, the rocker opens the valve and bleeds the air. After the pressure in the system decreases, the valve returns to its original position.

safety valve

In order to increase the safety of the boiler room and all heating equipment, an expansion tank is installed along with automatic control devices. As an additional protection, the safety group includes a safety valve designed to discharge “excess” liquid into the sewer.

In order to increase the safety of the boiler room and all heating equipment, an expansion tank is installed along with automatic control devices. As an additional protection, the safety group includes a safety valve designed to discharge “excess” liquid into the sewer.

IMPORTANT! To ensure that the boiler room is always dry, it is recommended to connect the safety valve to the drain into the sewer.

The protective element of the safety group in thermal energy generators performs the function of monitoring the pressure in the line with steam installations in the event of an emergency:

- automation failure;

- increasing the volume of coolant in case of thermostat failure;

- violation of the fluid flow pressure in the pipeline line.

The design of the safety valve includes a diaphragm and a steel spring, enclosed in a brass module with a valve or handle. If the system malfunctions by more than 15%, up to 100 ml of liquid is released through the control device in one release.There are various models of safety devices on the consumer market; when choosing a component for a heating boiler for individual use, you need to buy a valve that can withstand a pressure of 3 atmospheres and a liquid temperature of 120 °C.

Pressure gauge

In addition to the safety and bleed valves, a pressure gauge included in the boiler safety group will help monitor the situation. The indications of a household appliance are clear to any user due to the presence of arrows of different colors: red and black. The operating values of the red arrow are set manually in accordance with the boiler recommendations (about 2 atmospheres). The black arrow is controlled by the pressure of the working fluid in the pipeline line. If the indicators of the black arrow exceed the position of the red one, then the system is on the verge of an accident.

In addition to the safety and bleed valves, a pressure gauge included in the boiler safety group will help monitor the situation. The indications of a household appliance are clear to any user due to the presence of arrows of different colors: red and black. The operating values of the red arrow are set manually in accordance with the boiler recommendations (about 2 atmospheres). The black arrow is controlled by the pressure of the working fluid in the pipeline line. If the indicators of the black arrow exceed the position of the red one, then the system is on the verge of an accident.

When choosing a turnout set, you must consider the following factors:

- dial size;

- measurement accuracy;

- allowable error;

- measurement units (bars or atmospheres);

- permissible pressure.

For a private boiler room, a pressure gauge with a scale of up to 4 atmospheres is suitable.

IMPORTANT! For a private boiler room, the pressure of the working environment should fluctuate within 2–3 atmospheres.

Why do you need a security group?

The equipment unit for the safe operation of a heating water system is responsible for maintaining the standard indicators developed for each type of boiler room. All elements are combined by a manifold, the safety unit operates in automatic mode. If there is an expansion tank in the heat pipe line, installing the module does not make sense; the medium pressure is adjusted by discharging “excess” liquid directly into the tank.

The equipment unit for the safe operation of a heating water system is responsible for maintaining the standard indicators developed for each type of boiler room. All elements are combined by a manifold, the safety unit operates in automatic mode. If there is an expansion tank in the heat pipe line, installing the module does not make sense; the medium pressure is adjusted by discharging “excess” liquid directly into the tank.

Types of Security Group

The units responsible for the trouble-free operation of heating devices come in several types, differing:

- configuration;

- location of control elements;

- type of equipment;

- system configuration;

- boiler brand;

- method of installing a thermal installation.

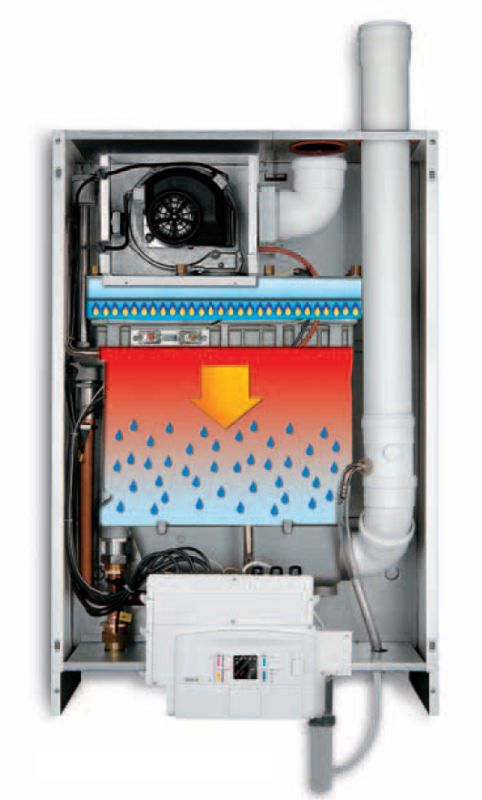

If a wall-mounted boiler is used for a private boiler room, then the safety unit is installed by the manufacturer on the rear panel of the equipment. For a floor-standing boiler, the safety group is selected individually.

Only a service technician can install and configure control devices correctly.