Do-it-yourself buffer tank for a solid fuel boiler

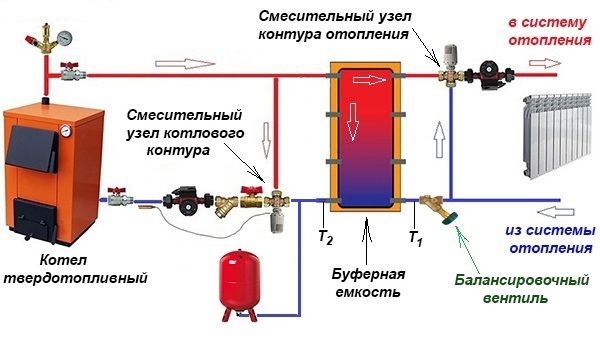

Solid fuel boilers are a good alternative to gas or electric. With all their advantages, they still have some disadvantages. Among them are uneven heat production and the impossibility of radically reducing the boiler power, which leads to irrational use of fuel. Also, especially during the cold period, the owner has to add firewood or coal to the firebox in the middle of the night, otherwise the heating will stop and the temperature in the room will drop noticeably. Installing a buffer tank in the system will help to cope with all these inconveniences.

Solid fuel boilers are a good alternative to gas or electric. With all their advantages, they still have some disadvantages. Among them are uneven heat production and the impossibility of radically reducing the boiler power, which leads to irrational use of fuel. Also, especially during the cold period, the owner has to add firewood or coal to the firebox in the middle of the night, otherwise the heating will stop and the temperature in the room will drop noticeably. Installing a buffer tank in the system will help to cope with all these inconveniences.

The content of the article

Why do you need a buffer tank?

The use of a buffer tank makes the heating system more autonomous and promotes rational consumption of solid fuel due to the accumulation of hot water in it. The main advantages of the installation include:

- Protects the system from damage due to overheating. Excess heat will be stored and used in the future.

- Economical and rational use of resources. The room will be heated evenly and there will be no need to open the windows if the temperature in it has risen above a comfortable one.

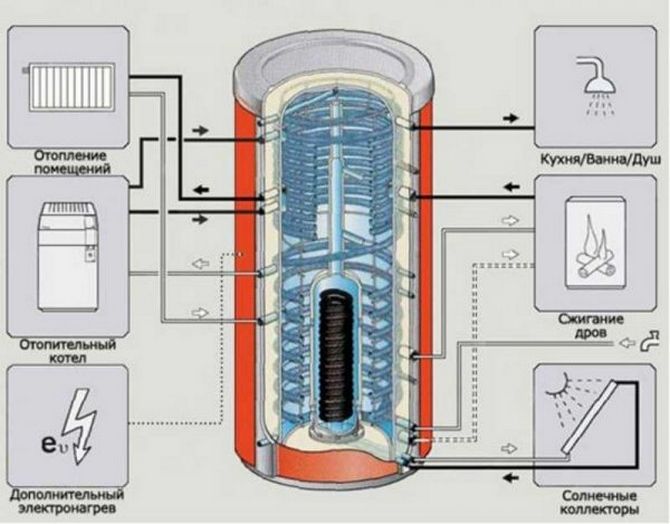

- The ability to easily connect other heat sources, for example, electric or gas boilers, into one system.

- Eliminates the need to get up in the middle of the night and add fuel. The accumulated heat will heat the room for some time.

IMPORTANT! Savings on energy consumption and overall efficiency when connecting a buffer tank to the heating system increase significantly. This happens without causing inconvenience or discomfort to residents.

There are also some disadvantages when using this device. The most significant of them are the rather high cost, heavy weight and dimensions. This complicates installation and requires a lot of space next to the boiler.

Calculation of buffer capacity

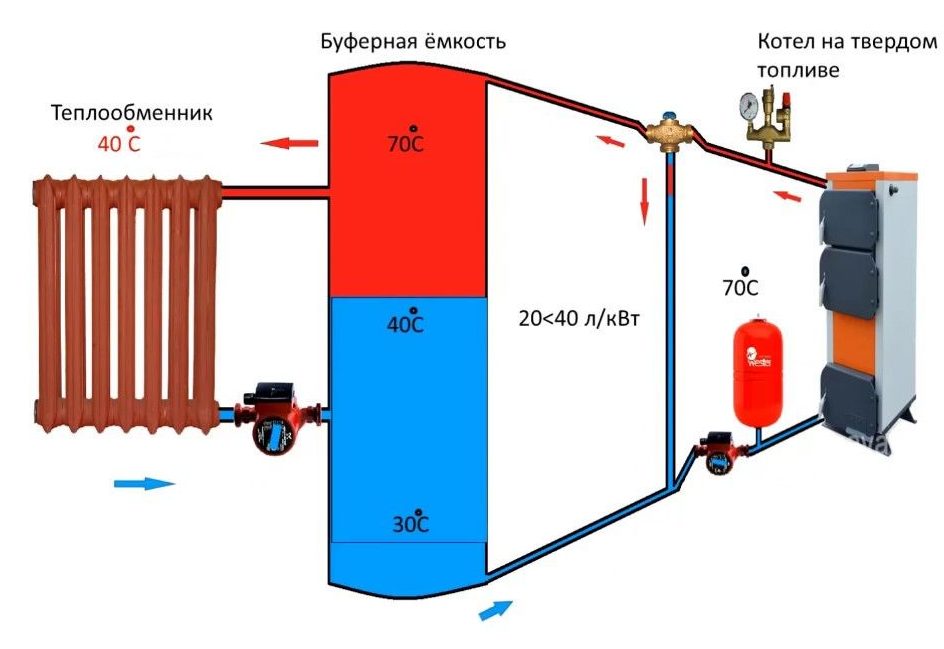

For maximum efficiency, it is important to choose the correct volume of the buffer tank. In this case, first of all, you should take into account the power of the boiler. The climate in the region is also an important factor. When calculating the volume of the future heat accumulator, you should be guided by the following nuances:

- The temperature of the coolant in the tank during complete combustion of one fill should not rise above forty degrees. To do this, the capacity should be approximately 20 to 55 liters per 1 kW of boiler power.

- You need to consider whether the container will fit in the room next to the boiler. If not, then you will have to make it less, but preferably more than 25 liters per kilowatt of power.

- It is important to pay attention to system downtime without a heat source. Determine the required supply of accumulated hot water in the tank so that it is enough for this time.

It is impossible to accurately calculate the capacity without special programs. Ideally, it would be good to hire a specialist for this.But if this is not possible, then you can approximately calculate it, you can know the heat capacity of water - 4.187 kJ/kg*C, the system downtime - in most cases up to 8 hours and the boiler power - most often it is 25 kilowatts per hour. IN In this case, the calculation will be as follows: with a temperature difference in the tank and the system of 25 degrees (25*3600) / (4.187*25) ≈ 0.86 m³ (860 liters). With a cylindrical shape, the tank should be approximately 100 cm in height and 104 cm in diameter.

Do-it-yourself buffer tank for a solid fuel boiler

Due to the high cost of factory-made analogues, many are considering the option of creating it themselves. This task is very non-trivial and will require a good knowledge of thermal and hydraulic engineering, as well as a high level of welding skills. Among the tools, you cannot do without welding equipment, an angle grinder, measuring instruments and a drill. You will also need a large amount of materials.

Materials

Since the project is complex and the size of the future storage tank is considerable, it will be quite expensive. You can't do without the following:

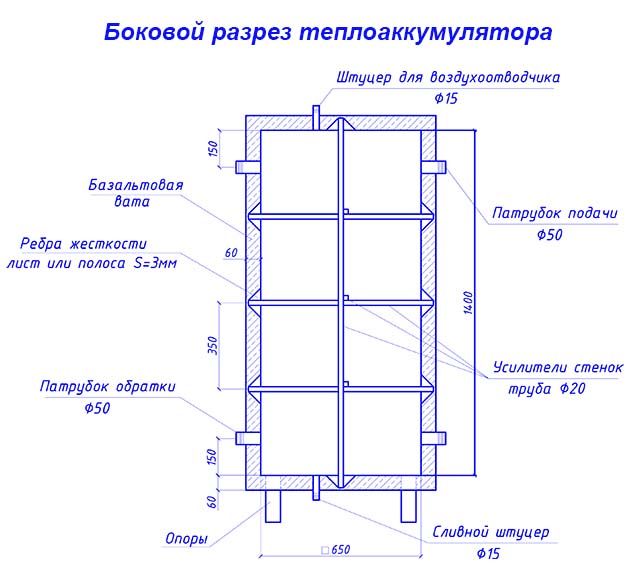

- If you decide to make it in the shape of a cylinder, you will need metal barrels (2 pieces). For a rectangular one, you will need a sheet, preferably stainless steel. It is important to pay attention to the thickness of this material, which should not be less than 1.5 (in the case of stainless steel) or 2 millimeters (with regular steel).

- Corner, profile pipe (5 by 5 centimeters). They will be used for the legs and stiffening ribs of the structure.

- Copper tube or stainless steel with a diameter of 12 mm. At least 10 meters will be required.

- Sleeves and fittings.

- Heat-resistant insulation. The best choice would be basalt wool, as it is easy to install and does not emit toxic substances when heated.

- Metal for cladding, preferably galvanized.

You will also need paint that is resistant to high temperatures.

Making a cylindrical container

To create a cylinder-shaped structure, 2 gas cylinders are suitable. They are easy to get, they have sufficient thickness and quality of metal.

ATTENTION! Before working with cylinders, make sure that any remaining gas is removed. Start cutting only after completely filling them with water to avoid explosion.

Main manufacturing stages:

- Cut barrels or cylinders. Cut off the covers.

- Weld inside the brackets on which the tube (heat exchanger) will be attached.

- Place the barrels on top of each other and connect them together by welding.

- Pass through the holes and install a coil made of copper or corrugated steel tube.

- Weld the bottom and lid. Into which there are pipes embedded for connecting the air release valve (top), drain valve (bottom).

- Attach fastenings for the outer cladding by welding. It is advisable to have different lengths (so that it turns out to be in the shape of a rectangle - this will be more convenient and the appearance will be more aesthetic).

It will not be possible to make a cylindrical tank from thick sheet steel without special equipment.

Creating a rectangular container

Produced in the following stages:

- Sheets of steel are marked according to the selected volume and pre-created drawings. Welding seams also have their own thickness, which should be taken into account.

- Cutting is done using a grinder.

- The sheets are installed and tacked by welding. For the correct angle of 90 degrees, you need to use measuring instruments and fix the parts.

- All sheets are welded. For reliability on both (internal and external) sides.

- Using the same scheme as with a cylindrical container, the lid and bottom are made.

- Fastenings for the sheathing, legs, and additional stiffening ribs are welded.

Installation of pipes

The pipes are mounted in holes prepared in advance for this purpose. They should be placed as follows:

- three fittings should be installed evenly along the entire height of the structure - thermometers are connected to them;

- a pipe is mounted to the top cover through a hole, to which the air release valve will be connected;

- at a distance of 30–50 cm from the bottom, 2 fittings are connected - through one of them hot water will flow into the tank, and through the second it will enter the heating system;

- near the bottom, respectively, there are also 2 pipes (one for returning the coolant to the boiler, the second from the system to the container);

- A tap is connected to the bottom to drain water if necessary.

Final stage

The last steps before starting operation will be:

- Cleaning, priming and painting the inside of the tank. It should be primed and painted several times.

- Afterwards, pre-prepared coils (heat exchangers) are connected.

- The tightness and reliability of the structure is checked. This is done using pressurized water.

- The outside of the tank is painted.

- Thermal insulation material is installed. The outer casing made of galvanized steel sheet is mounted on pre-prepared fastenings.

If it is possible to entrust this matter to professionals or buy a factory buffer tank, it is better to do so. Since its independent production requires extensive experience in welding and skills in thermal and hydraulic engineering. In addition, this will require a lot of resources, effort and time.