Gas convector using bottled gas gas consumption

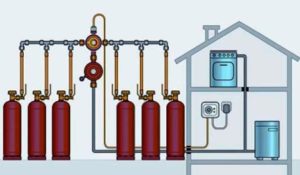

The issue of heating a living space today is solved by a number of different devices, unique in design and operating principle. So, when heating country houses and country houses, a bottled gas convector is best suited in terms of gas consumption.

The issue of heating a living space today is solved by a number of different devices, unique in design and operating principle. So, when heating country houses and country houses, a bottled gas convector is best suited in terms of gas consumption.

The content of the article

Features of the functioning of a convector using bottled gas

The operation of a gas convector using bottled gas is based on the phenomenon of convection - the process of transferring internal heat to the environment by flows of liquid or gas.

What does the device consist of?

To understand the principle of operation of the unit, you need to know what design parts it includes:

- Gas-burner. It burns the supplied gas and transfers the resulting heat to the heat exchanger;

- Heat exchanger. Air masses enter here and are further heated;

- Control module. Here the temperature is controlled and the gas supply volume is regulated;

- Chimney or coaxial pipe. From here, combustion products are released into the external environment.

- Frame.

Operating principle and distinctive features

Heating of the air in the convector occurs due to the movement of air masses inside the heat exchanger under the influence of forced or natural convection.In general, the operation of a heating apparatus can be described as follows:

- Gas enters the burner through a line or an attached cylinder, burns and heats the heat exchanger;

- Cold air entering the heat exchanger from below is heated and released through a special window or fan;

- The exhaust manifold traps combustion products and releases them through a chimney or coaxial pipe to the outside. From here, oxygen is also supplied in reverse order, necessary to maintain the combustion process.

All gas convectors are built on these principles.

Attention! Various technical solutions and the development of new design functionalities are designed to improve the quality of work and expand the scope of application of this device.

The heating equipment market offers a wide range of gas heating appliances, differing from each other in certain ways. When choosing a gas convector, you should pay attention to the following criteria:

- The material from which the heat exchanger is made. The service life of the unit as a whole depends on what material the heat exchanger is made of. The main materials are steel and cast iron. Models with a steel heat exchanger are cheaper than cast iron counterparts. This is due to the low rust resistance of steel and the simplicity of the production process. Proper operation of a device with a cast iron heat exchanger guarantees long-term operation for a period of 40-50 years.

- The amount of heat released. You need to choose a convector on the basis that, on average, at 10 m2 1 kW of heat energy is required. The larger the area of the room, the higher the efficiency value and the amount of heat generated should be.

- Combustion chamber type.There are two combustion chamber options: closed and open. Today, greater preference is given to the closed type. The difference between the closed and open type is that in the first case, a coaxial pipe is used instead of a chimney. It allows combustion products to be vented outside and fresh air to be taken in for the burner to operate. This technical solution significantly increases the cost of the device. In the usual version, instead of a pipe, a regular chimney is used, which removes carbon dioxide to the outside, and the flow of fresh air is ensured by ventilating the room.

- Characteristics of the energy carrier. The amount of heat released during the combustion of natural fuel also depends on its composition and chemical properties. Liquefied propane gas is in greatest demand.

- Installation method. According to the installation method, all models can be divided into floor-mounted and wall-mounted. The first type is characterized by increased weight, since they have a fairly voluminous heat exchanger installed. A wall-mounted convector weighs less than a floor-mounted one, takes up less space and develops a power of up to 10 kW.

- Convection type. The use of additional fans in the design increases the speed of distribution of warm air masses in the room. The principle of forced convection works here, when fans artificially move air inside the heat exchanger. With natural convection, the heating rate is low, but the operation of the device is practically inaudible, relieving the hearing of possible irritating sounds.

- Automation of device operation control. Many modern gas convectors are equipped with electronic control devices.With their help, you can regulate the air temperature and set the desired heating mode.

Important! When choosing a gas convector, before purchasing, be sure to check the chimney or coaxial pipe for serviceability. During the inspection, no visible mechanical damage or signs thereof should be detected.

Calculation of power and gas consumption

Calculation of power and gas consumption depends on many parameters and factors related to both the characteristics of the device and environmental conditions.

Power

There is a special formula that allows you to calculate the average power of a gas convector. It looks like this: P = k*S, where:

- P – power;

- k – coefficient taking into account the type of system and operating conditions. Also called correction factor;

- S – area of the room.

The k value for balloon heating is taken as 0.1. If the only source of heat in the room is a gas convector, then this value is 0.12. In walk-through and infrequently visited premises, the coefficient is 0.15.

Consumption

When calculating gas consumption, the following parameters are taken into account:

- room size;

- operating mode;

- thermal insulation.

Thus, for 1 kW of output power when a convector is operating, there is usually 0.11 m3 natural gas or 0.09 kg of bottled gas (in our case).

Important! If we analyze the calculations, it turns out that the energy consumption of electric convectors is much higher than the consumption of gas convectors that consume gas through special lines, which is their distinctive advantage.

However, the benefits of using convectors running on bottled gas are negligible in terms of energy consumption.It is recommended to use such devices for autonomous provision of heat to rooms.