Do-it-yourself vibrating plate: how easy and realistic is it to do?

A do-it-yourself vibrating plate is usually made using an electric motor. It is not as productive, but it does not emit emissions and is not so noisy. In addition, it is quite suitable for household purposes, and the cost is not that expensive. How to draw up a drawing and correctly assemble the unit is described step by step in this material.

The content of the article

Device and drawing

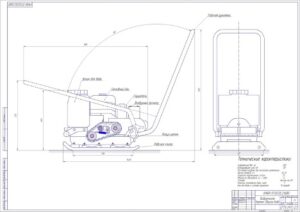

Before creating a vibrating plate with your own hands with an electric motor, you need to familiarize yourself with the structure of the mechanism and draw up a drawing. The tamper consists of several elements, as shown in the diagram.

Manufacturing begins with a metal base. You can use a steel part as a basis - cast iron is not used because it can crack. In addition, it cannot be welded; the material is fragile. To understand how to make a vibrating screed, you need to take a sheet of steel, the thickness of which is at least 8 mm. Several elements must be attached to it to increase the mass.

If you make a high-quality vibrating screed with your own hands, you need to understand that its efficiency is directly related to its weight, base area and shaft rotation. The surface may be too large - then the pressure will be insufficient. And if the area turns out to be small, then the impact force will be point-like. If the vibration is too intense, the tool will quickly fail.

Therefore, before starting work, you should decide on the dimensions of each element.You can take a ready-made drawing as a basis and, if necessary, modify it to suit your case. A do-it-yourself vibrating screed for concrete (using the example of a gasoline model) can be made according to this scheme.

Materials and tools

Also at the preparatory stage you need to figure out what materials and tools will be needed. First of all, you need to think about the engine. At home, a homemade vibrating plate is often powered by an electric motor. It is not as powerful compared to petrol or diesel. But the unit is less noisy and does not produce any emissions. If necessary, it can also be used indoors.

Standard vibrators that can be purchased in almost any store are models IV-98 and IV-99. On average they cost 7,000-10,000 rubles. When choosing a power supply, it is better to focus on the standard voltage of 220 V. Also, an electric vibrating plate can be made with your own hands using the following available materials and tools:

- a piece of steel sheet from 8 mm (you can use a piece from a machine);

- 2 channels for the engine;

- fastening element - bolts;

- metal pipe (cuts);

- material that absorbs vibration (the handle needs to be insulated);

- wheels;

- hammer;

- Bulgarian;

- welding machine;

- construction tape.

Step-by-step instruction

After drawing up the drawing and purchasing the engine, as well as the necessary materials, you can proceed directly to the manufacture of the tool. A vibrating plate for soil compaction is made in several stages:

- The metal sheet is cut to a depth of 5 mm with a margin of 1 cm from the edges.

- The edges are folded using a hammer. As a result, the “wings” should be located at an angle of approximately 25 degrees.If you make a vibrating plate with your own hands with a gasoline engine, this rule is also observed. Thanks to the “wings” the surface does not get buried in sand or other material during operation.

- The cuts are immediately fixed by welding, otherwise the bent parts may fall off.

- Next, you need to understand how to make a vibrating plate with your own hands. At the next stage, they work with a welding machine. With its help, 2 channels are fixed directly in the center. They are located along parallel straight lines with an interval of 7-8 cm. In this case, both fragments run perpendicular to the slab itself. The result is a blank like this.

- Drill several holes for bolts on the surface of the channels - M10 or M20 are suitable for these purposes.

- Now it’s easy to understand how to make a tamper with your own hands. At this stage, the vibrator is attached to the plate and the bolts are screwed in.

- Now you need to secure the handles. They can be installed directly on the stove, but your hands get tired pretty quickly during operation. Therefore, it is better to install cushion pads.

- At the intermediate stage, the workpiece will look like this.

- The handle is welded from a metal pipe. In this case, you need to take into account the drawing, as well as your height. The place where the hands will be is wrapped, laying soft material. If you don't have one, you can simply make a rope loop.

- Since the finished unit must weigh at least 60 kg, wheels must also be installed. First, a small fragment is cut from the metal pipe and welded to the plate. If you use a homemade vibrating plate with a gasoline engine as a basis, it is better to take metal wheels - plastic ones may not withstand it.

Thus, a do-it-yourself tamper can be quite easily made at home using available materials and equipment. The biggest cost will be on the engine.But even taking this into account, your own tool will cost much less. In addition, you can customize it specifically for yourself by making a handle of the desired height.