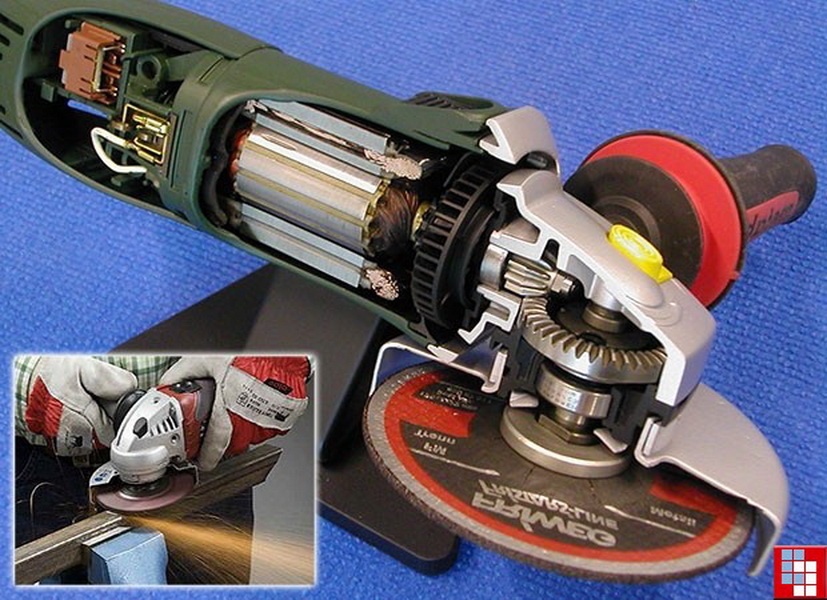

The device of the grinder

Almost every man has an angle grinder in his household. This is a very common, versatile and highly sought after tool. During operation, it experiences serious stress, and it is used often. All this leads to the fact that sometimes she begins to behave in strange ways. When starting, there are jerks, there is a smell of burning, and other manifestations of abnormal operation appear. All this makes you think that the device is faulty. But it’s too early to despair and buy a new one. Many failures can be eliminated on your own. The main thing is to know what and how this device works.

The content of the article

The structure of the grinder, its main parts

Like any power tool, an angle grinder includes several elements. These are the housing, engine, gearbox, coupling and others. Let's look at the main ones.

Frame

It is made of durable plastic. Consists of two parts that are connected by bolts. To cool the engine, holes are made in the housing.

Engine

It consists of the following components:

- Stator. It is represented by two-pole coils with a copper winding. They are coated with a strictly defined number of turns of copper wire. It is indicated in the technical documentation for the product.

- Rotor. Located in the stator. Attached with bearings. The first bearing is located inside the gearbox housing, and the second is mounted on a plastic housing and is located near the manifold.The rotor is made of special electrical metal. It has slots in which the winding wires are located. The speed of rotation directly depends on the number of slots and the pitch of the winding.

- Electric brushes. Thanks to them, electrical energy flows through the cable to the collector. If they function properly, then their even glow can be seen through the ventilation holes. Otherwise, it becomes intermittent or not visible at all.

Gearbox

The housing for this element is made of strong aluminum alloy; it has good thermal conductivity. The remaining elements are fixed on it. It has a hole for a second handle to make it more convenient to use the grinder.

Electrical energy is supplied from the armature, which is in rotation to the cutting wheel through the editor. How many revolutions the cutting disc makes depends on the gearbox.

It consists of the following elements:

- A pair of bearings are installed on the axis, thanks to which the driven planetary gear rotates.

- On one side of the shaft there is a thread onto which a nut is screwed to hold the cutting disc.

- A gear is installed on the anchor axis, which plays a leading role for the bevel one.

Other elements

These include:

- Release clutch. This device prevents kickback if the cutting disc becomes stuck. It looks like two disks that are pressed very tightly against each other. This prevents the rotor shaft from stopping abruptly during rotation.

- Spindle speed regulator. This device is optional and is not installed on every model.

- Engine start and soft start switch.Thanks to this button, after putting the tool into action, the stroke does not increase immediately, but gradually. This reduces the load on the engine and also reduces the likelihood of injury.

- SJS system. Designed to protect the motor from overloads. The latter are natural in cases where the cutting disc gets stuck in the material. But such a system is not installed in every grinding machine.

- Button for quick replacement of cutting disc. Blocks the gear of the gearbox when the fixing nut is unscrewed.

- Nut securing the circle. To clamp the disk, you must use a special key.

Principle of operation

No matter how different the Bulgarians may be in appearance, they operate on the same principle.

As soon as the start button is pressed, electric current is supplied to the motor and the rotor begins to move. From it, rotation goes to the rotor shaft gear. The latter, through the large gear of the gearbox, rotates the axis ninety degrees. The gear of the gearbox is fixed inside its housing. It is thanks to this that the gear, rotating, sets the cutting disc in motion.