How to harden an ax at home?

Ax hardening is a heat treatment that involves heating the metal to a very high temperature and then rapidly cooling it. The purpose of the procedure is to improve such material characteristics, both hardness and strength, reduce its ductility. It requires adherence to certain technology, but overall it is a simple process. If necessary, you can do it yourself.

The content of the article

How to understand whether hardening is needed

First, you should check whether such a procedure is required. Not all manufacturers produce high quality products. It happens that the purchased ax was either not hardened at all, or it was carried out in violation of the process:

- in the first case, the material of the tool will be too soft, and this leads to the appearance of dents and nicks, as well as to rapid dulling during use;

- a violation of technology, as a rule, consists in excluding the tempering stage after heating from the process - the metal is brittle and quickly becomes covered with cracks.

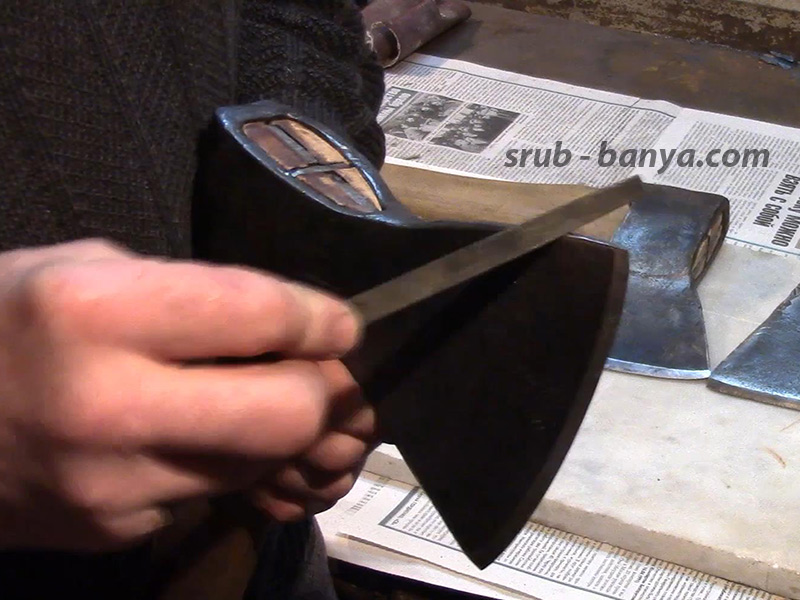

Compliance with quality requirements is checked using a flat file. You need to take it with a fine notch. If it glides freely over the surface without catching it or leaving marks, this indicates the high hardness of the alloy.

If, by all indications, the tool needs to be hardened, it is necessary to determine what kind of steel was used to make it. This is necessary for proper processing.

The best steel used for a quality ax is carbon. It is marked U7, U8, U8A.

How to harden an ax yourself

Heat treatment consists of several stages.

The metal has a non-uniform crystal lattice. When it goes through the stages of heating and forging, the crystals are destroyed and their structure changes.

In order for steel to acquire hardness, it is necessary to achieve a special arrangement of carbon molecules in the crystal lattice. This structure is called stressed or martensitic.

Annealing

During this procedure, under the influence of very high temperatures, a metal characterized by a homogeneous structure is obtained. Its peculiarity is the absence of tension in the crystal lattice. The material becomes soft and becomes “pliable” for mechanical processing. An ordinary brick oven is suitable for annealing.

Before proceeding directly to annealing, you need to remove the cutting edge by grinding so that its thickness becomes 1 mm. Under thermal influence, the sharpening will still melt. Now you can start heating.

The process looks like this:

- The ax is heated until red (this corresponds to a temperature above 750-800 degrees) - in a furnace or forge.

- Then the instrument is allowed to cool, along with the stove or coals.

After annealing, the alloy can be easily processed with metal-cutting tools.

Hardening stage

Hardening involves heating and rapid cooling in water or oil (pure diesel).

Depending on the brand of alloy that became the raw material for the working part of the tool, the temperature regime may differ slightly. Information about this is available in reference books on metallurgy. Heating of products marked U7 and U8 is increased to 800 degrees.

A magnet will help determine the temperature. Steel stops being magnetic at 760 degrees.

Further:

- After the alloy has stopped reacting to the magnet, it is heated for a few more minutes. The product being processed should turn bright red. To determine heating temperatures by shade, you can use a table.

- A hot tool is cooled by immersion in water. It should not be too cold - the optimal temperature is 30 degrees. Immerse the cutting edge for a couple of seconds. In this case, the ax must be moved so that the so-called fur coat of steam does not appear.

- Then the instrument is completely immersed in oil, the temperature of which should be 50-60 degrees. Precautions must be taken as the liquid may ignite. You need to wait until the product cools down and remove it.

For hardening, sometimes only oil is used. Scale deposits are removed with an iron brush.

Vacation

The procedure relieves excess stress in the metal. Then it becomes viscous. The process takes place at 300 degrees. It takes about an hour, then the blade cools in the air.

An oven with the ability to set the temperature is best suited for the process. The instrument is placed in a chamber where the temperature is 300 °C.

If the processing is carried out correctly, the alloy should turn blue.

To check the effectiveness of all procedures, you need to use a file - how to do this was described above. Hardening an ax requires care, caution, and adherence to technology. However, in general it is quite simple and can be done by many people.