How to sharpen an ax with a grinder

The condition of any tool determines the quality and efficiency of its use. Blade sharpness is the main indicator that affects normal operation ax. To ensure this, regular and correct sharpening is important. There are various ways to edit the main working element of the tool - using an electric sharpener, sandpaper, an abrasive stone, or an angle grinder. Let's look into the nuances of using the latter at home.

The content of the article

Sharpening an ax with a grinder: the right steps

To ensure the safety and efficiency of the process you should:

- Make sure you have a special disc designed for sharpening - the use of a cutting wheel is prohibited.

- Fix the grinding wheel - it is necessary to remove the casing and use special fasteners to tighten it.

- Place the angle grinder in a vice and securely fasten it.

- Treat the surfaces of the blade, alternately passing through different planes.

Attention! Before starting work, you should protect yourself by using personal protective equipment.

A grinder is used for processing the working elements of axes if the latter are made of high-quality steel. The disadvantage of this method is that it is not possible to regulate the rotation speed. This leads to overheating of the edge and a change in the properties of the material.

If you neglect to fix the angle grinder, the risk of wheel runout will increase and the angle will not be maintained.The blade will be damaged and the thickness will vary in different areas.

What to consider to ensure sharpening is correct

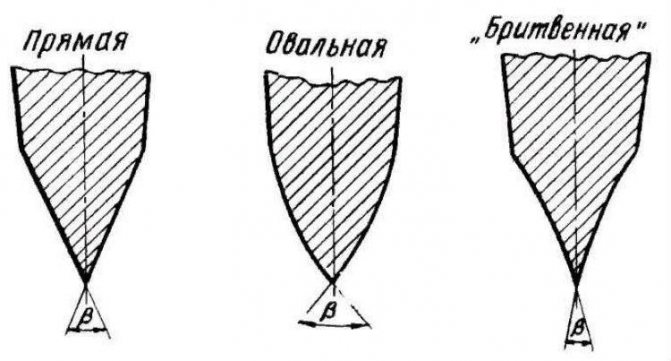

The optimal method for editing the working part depends on several parameters. In particular, on the scope of application. Sharpening can be:

- straight - suitable for rough work, which includes chopping wood and cutting down trees;

- oval - ideal for precise manipulations, called universal because it is suitable for many types of use;

- razor - for highly specialized tools.

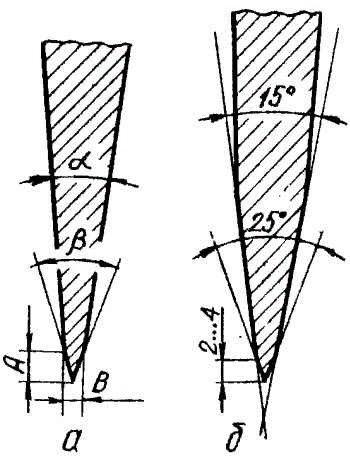

The sharpness of the working part depends on two main indicators: the sharpening angle and the width of the chamfers.

Angle options

Before you start processing, it is worth making a sample of the correct angle. To do this you need:

- take a piece of hard material and apply markings;

- cut out the desired shape using metal scissors;

- attach it to the edge, mark the areas on the blade for editing.

According to GOST, the sharpening angle should be different if the tool is used for different types of work - carpentry, construction. Taking this into account, the values should be 45° or up to 30°, respectively.

The given parameters are not considered rigid and may change.

The sharpness directly depends on the angle of sharpening - the smaller it is, the sharper it is. However, excessive sharpening of the working surface can lead to its rapid dulling. In addition, the tool will get stuck in the wood pulp when chopping firewood.

Chamfer width

This parameter represents the distance from the cutting section to the side surface. The service life of the tool depends on its size, as well as how sharp the blade is.

If the chamfer wears out during operation, a rebound from the surface of the barrel may occur. To edit the working part and ensure efficient use, a double escapement is used.This is a processing method when the first angle is 15°, and further sharpening is carried out in accordance with the purpose of the tool.

Using an angle grinder for such work is quite dangerous. You must be careful, take precautions and use personal protective equipment.

Grinder - angle grinder! There is a special machine for sharpening tools - it’s called a sharpening machine! Well, buy it already if you are so good at sharpening angles! Or do it yourself! But, probably, the author is very economical. And the next article will be “how to shave with an ax sharpened by a grinder”!